A kind of manufacturing method of bamboo fiber non-iron shirt

A production method and bamboo fiber technology, applied in the field of garment processing, can solve the problems of easy shrinkage, easy wrinkling, easy deformation, etc., and achieve the effect of not easy to shrink, not easy to yellow, and maintain strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

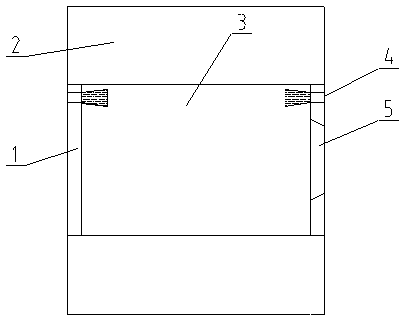

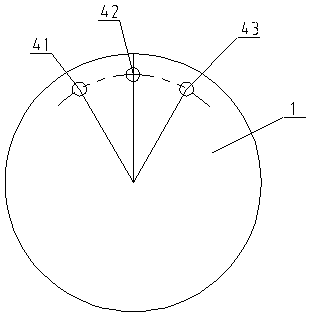

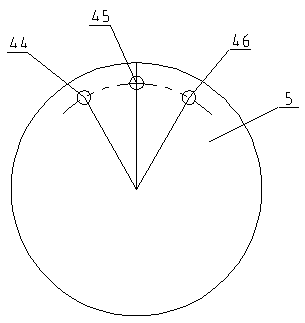

Image

Examples

Embodiment 1

[0022] The concrete steps of this embodiment are as follows:

[0023] 1. The processing of bamboo fiber fabrics: first put the bamboo fiber fabrics into the bleaching liquid and boil for 30min. Sodium acid sodium 5g / L, penetrating agent 5g / L, scouring agent 3g / L and oxygen bleaching stabilizer 5g / L, rinse twice with cold water after boiling and bleaching, and then wash with hot water at 100°C until the bamboo fiber fabric is boiled and bleached. The liquid is neutral, and then rinsed with cold water and dried for later use. The penetrating agent is JFC, the refining agent is ZJ-CH60 low-temperature refining agent, and the oxygen bleaching agent includes the following components by weight: ethylenediamine 5 parts of sodium tetraacetate, 8 parts of sodium hexametasulfate, 2 parts of hydroxyethylene diphosphate, 3 parts of boric acid, 2 parts of acrylic acid, 2 parts of magnesium sulfate, 2 parts of marmic acid, 0.5 parts of acrylamide, 100 parts of water;

[0024] 2. Garment ma...

Embodiment 2

[0036] The concrete steps of this embodiment are as follows:

[0037] 1. The processing of bamboo fiber fabrics: first put bamboo fiber fabrics into the bleaching liquid and boil for 45min, the bleaching temperature is 95°C, the bath ratio is 1:32, and the bleaching liquid contains 30% hydrogen peroxide 8g / L, silicon Sodium acid 7.5g / L, penetrating agent 6g / L, scouring agent 4g / L and oxygen bleaching stabilizer 6g / L, rinse with cold water for 2-3 times after boiling and bleaching, and then wash with hot water at 95℃ to the bamboo fiber fabric The decoction and bleaching liquid is neutral, and then rinsed with cold water and dried for later use. The penetrating agent is JFC, and the refining agent is ZJ-CH60 low-temperature refining agent. The oxygen bleaching agent includes the following components by weight: B 8 parts of sodium diamine tetraacetate, 3 parts of sodium hexametasulfate, 4 parts of hydroxyethylene diphosphate, 4 parts of boric acid, 2.5 parts of acrylic acid, 2.5...

Embodiment 3

[0050] The concrete steps of this embodiment are as follows:

[0051] 1. The processing of bamboo fiber fabrics: first put bamboo fiber fabrics into the bleaching liquid and boil for 60min, the bleaching temperature is 90°C, the bath ratio is 1:35, and the bleaching liquid contains 30% hydrogen peroxide 10g / L, silicon Sodium acid sodium 10g / L, penetrating agent 8g / L, scouring agent 5g / L and oxygen bleaching stabilizer 8g / L, rinse with cold water for 2 to 3 times after boiling and bleaching, and then wash with hot water at 90°C until the bamboo fiber fabric is clean. The bleaching liquid is neutral, and then rinsed with cold water and dried for later use. The penetrant is JFC, the refining agent is ZJ-CH60 low-temperature refining agent, and the oxygen bleaching agent includes the following components by weight: 10 parts of sodium amine tetraacetate, 3 parts of sodium hexametasulfate, 2 parts of hydroxyethylene diphosphate, 5 parts of boric acid, 3 parts of acrylic acid, 3 part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com