Single-bar, single-mesh and anti-crack type precast concrete pavement slab convenient to carry, disassemble and assemble and using method of precast concrete pavement slab

A technology of prefabricated concrete and pavement, which is applied to pavements, roads, roads and other directions paved with prefabricated blocks, can solve problems such as high cost, environmental pollution, increase urban environmental pollution, etc., and achieve the effect of preventing horizontal displacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

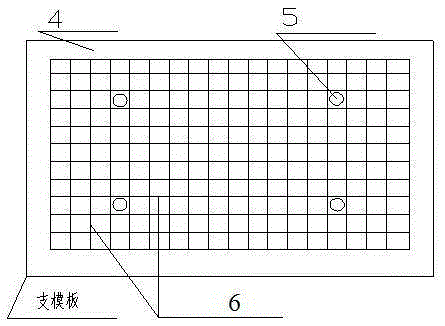

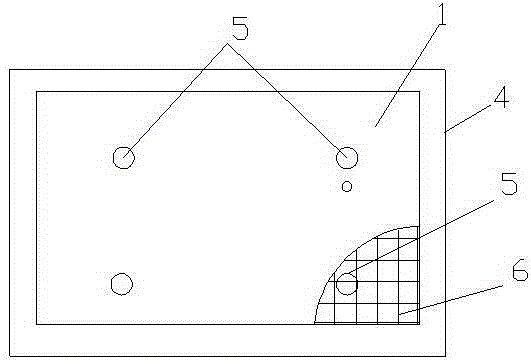

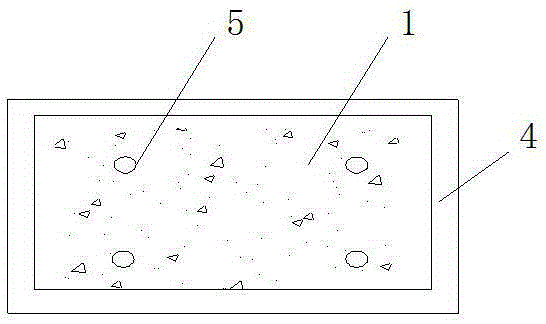

[0029] like Figure 1-8 As shown, the portable disassembled single-reinforcement, single-network, crack-resistant precast concrete road slab includes slab main body 1, bottom layer 2, surface layer 3, pre-embedded angle steel 4, pre-embedded steel pipe 5, slab main body 1 is made of concrete It is poured and the concrete is C20 grade concrete. The shape of the main body 1 of the slab is rectangular or fan-shaped, and the prefabricated concrete slab can meet the requirements of a 90° or 45° turn of the road on the construction site. A pipe 11 of Φ50 is pre-buried in the main body 1 of the panel along the length side, and a surface layer 3 is arranged above the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com