Shock absorbing system for forging hammer

A shock absorption system and forging hammer technology, applied in construction, infrastructure engineering and other directions, can solve the problems of poor shock absorption effect, not very good damping effect, large impact vibration of forging hammer, etc., to achieve easy installation and maintenance, shock absorption effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

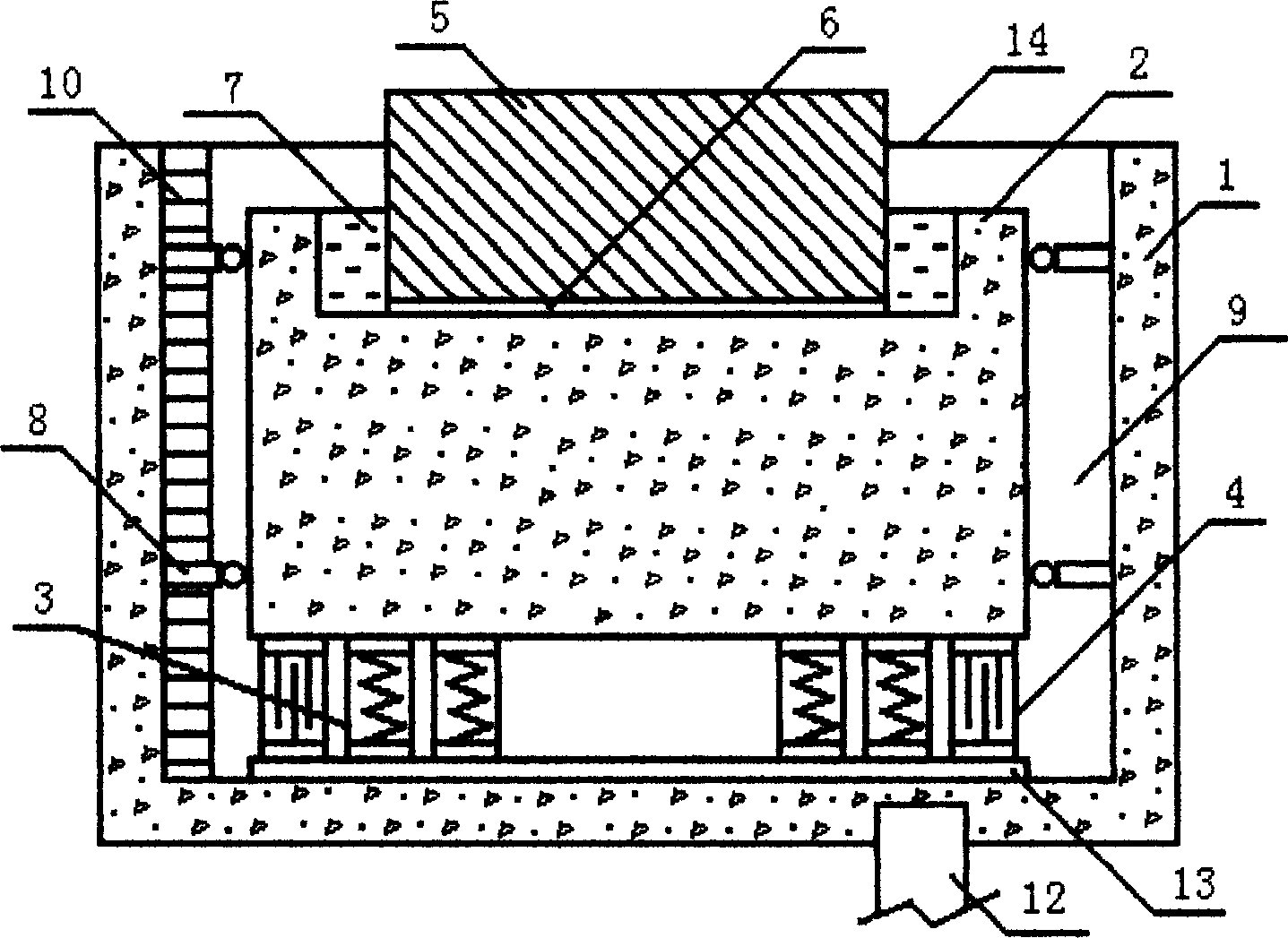

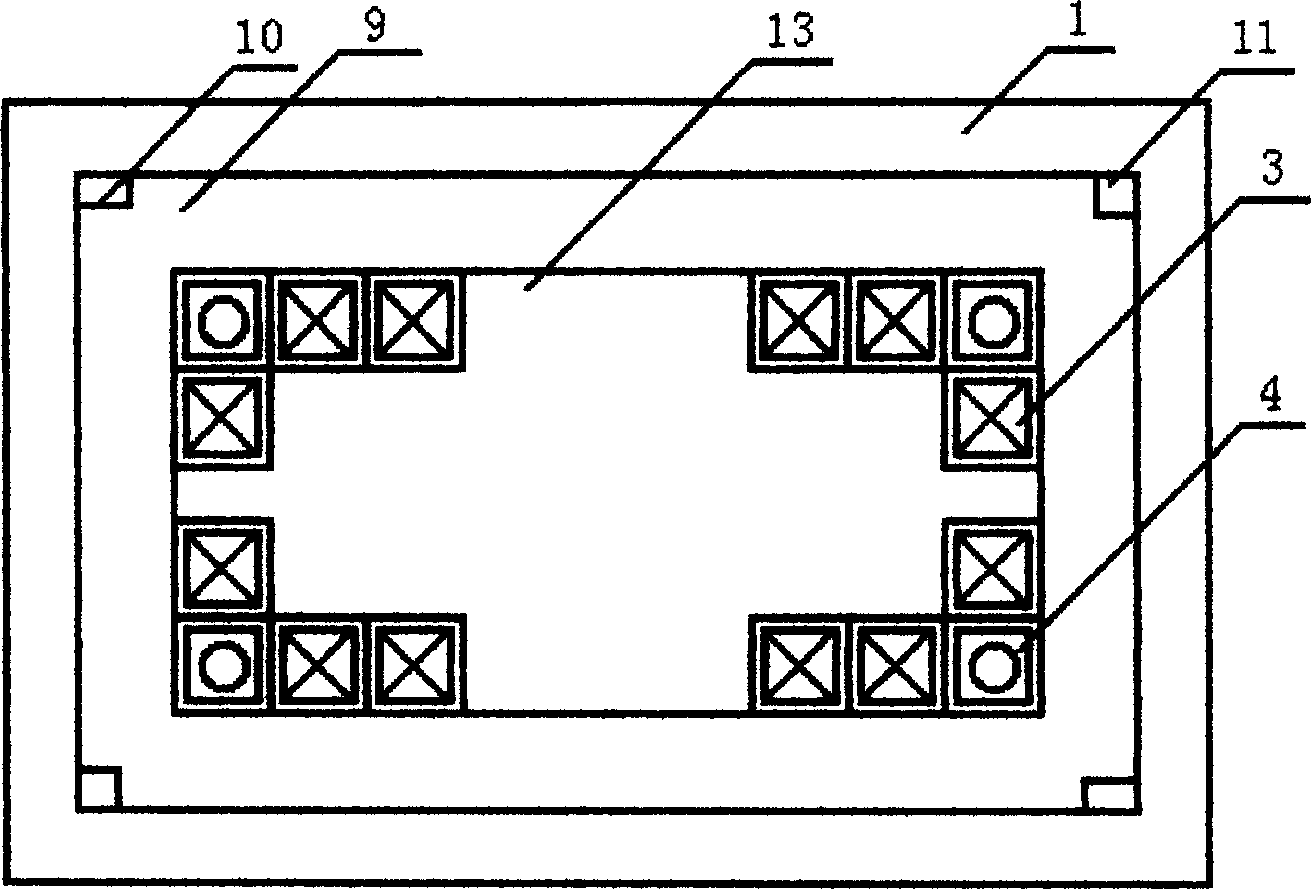

[0013] Such as figure 1 , 2 As shown, the forging hammer damping system is composed of large foundation 1, small foundation 2, shock absorber 3, and damper 4. The large foundation 1 and small foundation 2 are reinforced concrete structures, and the shock absorber 3 and damper 4 are located on the large foundation. Between 1 and small foundation 2, there is a groove on the small foundation 2, the anvil 5 is located in the groove, there is a rubber pad 6 between the anvil 5 and the small foundation 2, and the surrounding is filled with clay 7 and compacted, and the small foundation 2 is limited Bit 8.

[0014] Steel spacer 13 is arranged under shock absorber 3, damper 4.

[0015] There is a maintenance well 9 between the large foundation 1 and the small foundation 2, and a ladder 10 is arranged in the maintenance well 9.

[0016] There is a sump 11 at the bottom of the large foundation 1 .

[0017] There are reinforced concrete piles 12 deep into the underground rock layer a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com