Ultra-low wall loss submicron terminal virtual impactor

A virtual impactor and sub-micron technology, applied in scientific instruments, measuring devices, particle size analysis, etc., can solve the problems of large content of small-sized particles, insufficient separation accuracy, and large wall loss of aerosol particles, so as to reduce wall loss. , The effect of low wall loss and improved separation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings of the specification.

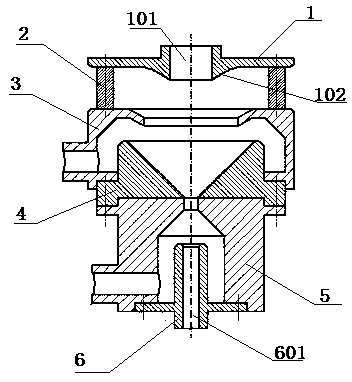

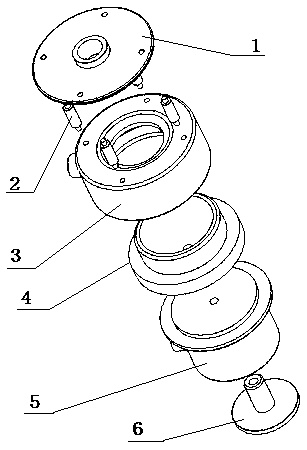

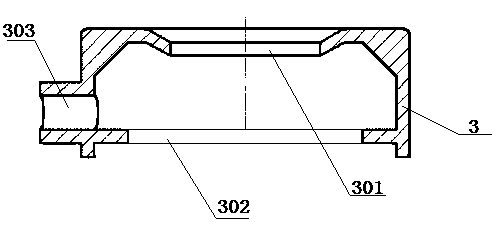

[0025] Such as figure 1 , figure 2 , image 3 As shown, an ultra-low wall loss sub-micron terminal virtual impactor includes: internal flow inlet 1, positioning stud 2, side flow cavity 3, acceleration nozzle 4, small particle size particle collection cavity 5, large particle size particle collection In the cavity 6, the inner flow inlet 1 is fixedly connected to the top wall of the side flow cavity 3 through the positioning stud 2, and the bottom wall of the side flow cavity 3 is fixedly connected to the acceleration nozzle 4, and the upper end of the acceleration nozzle 4 is located inside the side flow cavity 3 to accelerate The lower end of the nozzle 4 is fixedly connected to the upper end of the small particle collection chamber 5, the lower end of the small particle collection chamber 5 is fixedly connected to the large particle colle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com