Point discharge micro-plasma atomic emission spectrum analysis device in argon-hydrogen flame

A technology of atomic emission spectroscopy and micro plasma, which is applied in the field of atomic emission spectroscopy analysis, can solve the problems of limited excitation efficiency and achieve the effects of low cost, low energy consumption and reduced impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

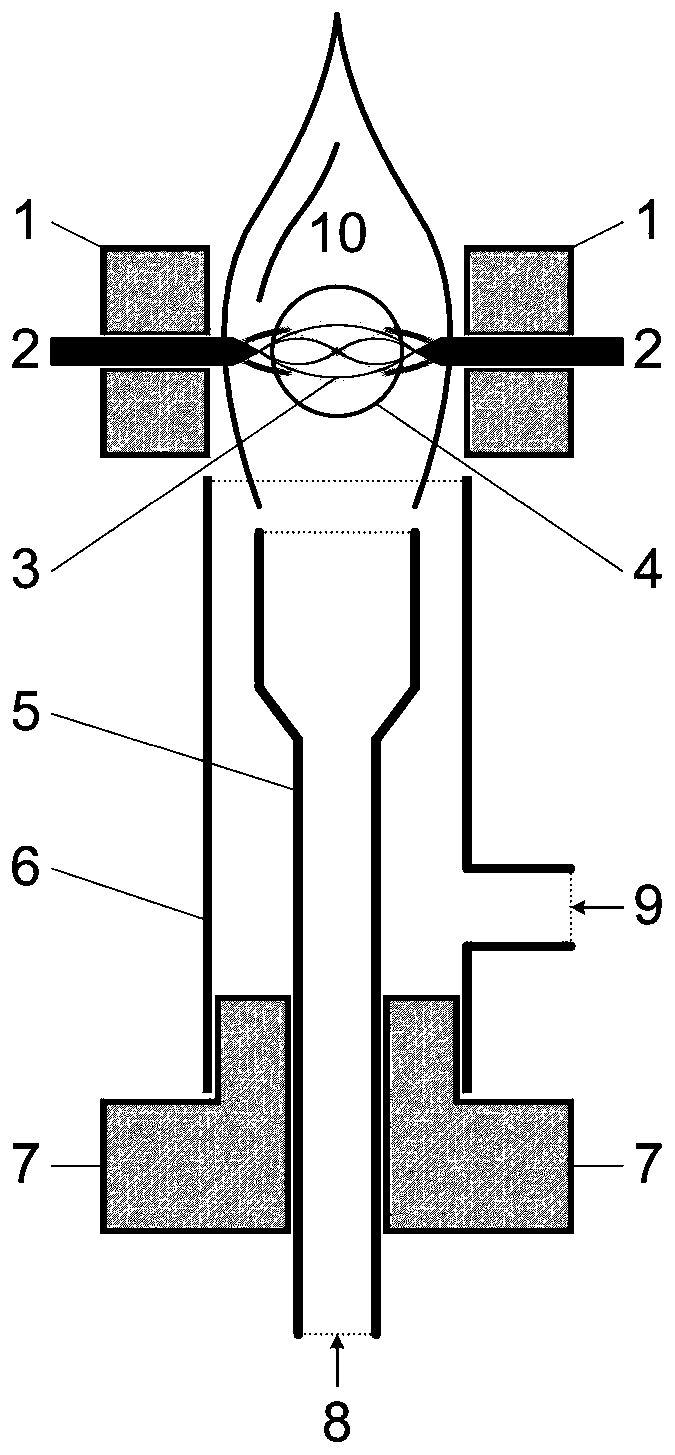

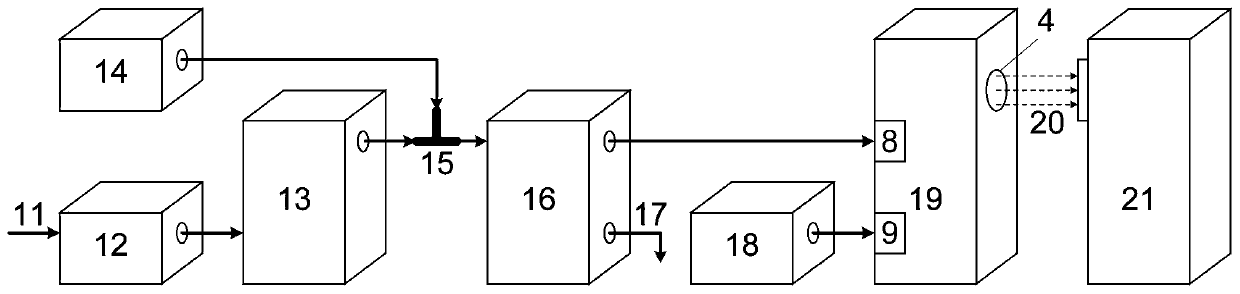

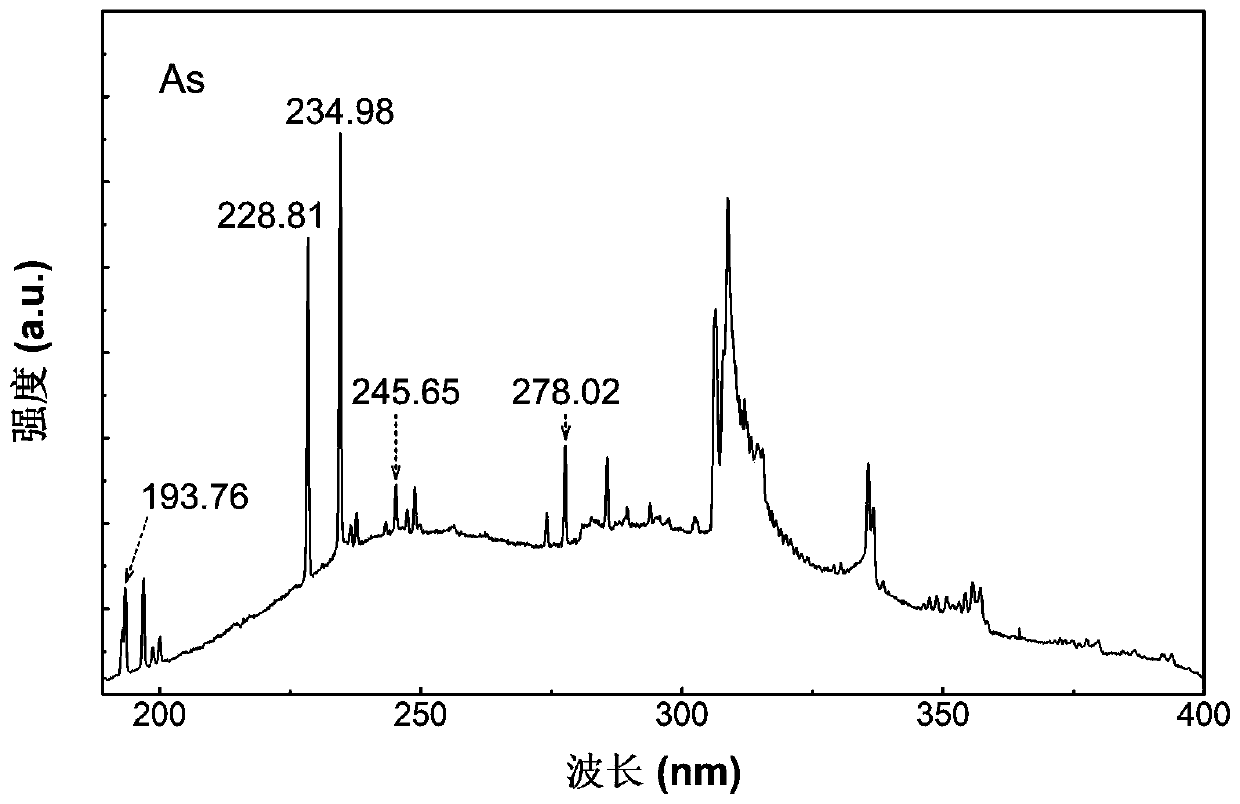

[0056] Embodiment 1: the tip discharge micro-plasma atomic emission spectrum excitation source and analysis device (such as figure 1 with 2 shown), the sample solution containing arsenic (As) (containing low-concentration hydrochloric acid) and the hydride generating reagent (containing low-concentration borohydride) are pumped into the chemical vapor generating reactor 13 through the peristaltic pump 12 to merge and react to produce Volatile hydride, the reaction solution is mixed with the working carrier gas of the working carrier gas system 14 through the three-way mixer 15 at the rear end of the chemical vapor generating reactor 13, and then enters the gas-liquid separator 16 to realize gas-liquid separation, and the waste liquid It is discharged from the waste liquid outlet 17. The separated sample vapor continues to be brought into the atomic emission spectrometry excitation source 19 by the working carrier gas, and first further removes moisture and matrix in the argon...

Embodiment 2

[0057] Embodiment 2: Similar to Example 1, the sample solution containing bismuth (Bi) passes through the tip discharge micro-plasma atomic emission spectrum excitation source and analysis device (such as in the argon-hydrogen flame of the present invention) figure 1 with 2 Shown) is analyzed, and the characteristic atomic emission spectrogram finally obtained, such as Figure 4 shown.

Embodiment 3

[0058] Embodiment 3: Similar to Example 1, the sample solution containing germanium (Ge) passes through the tip discharge micro-plasma atomic emission spectrum excitation source and analysis device (such as in the argon hydrogen flame of the present invention) figure 1 with 2 Shown) is analyzed, and the characteristic atomic emission spectrogram finally obtained, such as Figure 5 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com