Crushing and cleaning equipment for metal packaging container

A technology for cleaning equipment and metal packaging, used in transportation and packaging, lighting and heating equipment, chemical instruments and methods, etc., to achieve high production efficiency, reduce impurity content, and avoid fire.

Pending Publication Date: 2022-06-10

HUANCHUANG XIAMEN TECH

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, due to the inevitable generation of a large amount of dust in processes such as crushing and sorting, air pollution is caused.

In addition, the existing crushing and cleaning equipment for metal packaging containers usually first directly crush the metal packaging containers. The impurity rate is relatively high, and it is easy to catch fire during crushing, especially when the sorted materials contain more flammable non-metallic substances or flammable liquids, it is more likely to catch fire, which has certain safety hazards, and because the sorted materials The impurity content is relatively high, and the cleaning difficulty is relatively high, and if it is not cleaned, it will affect the quality of the recycled metal aggregate

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

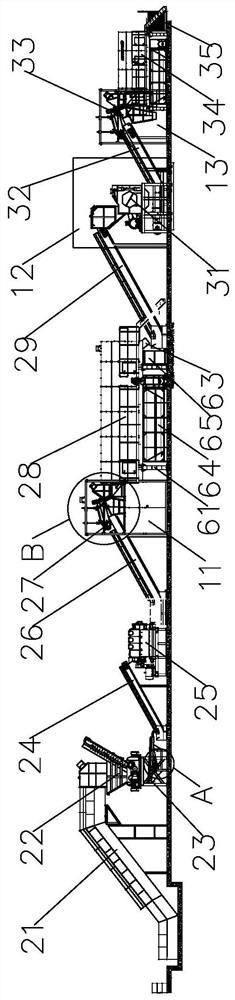

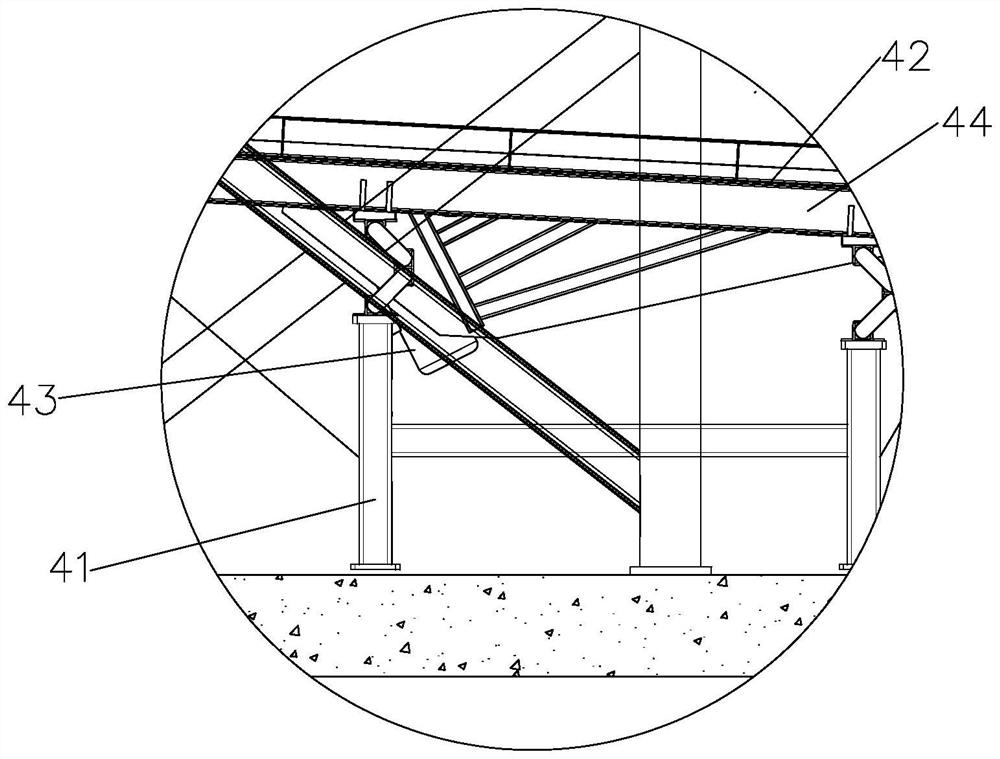

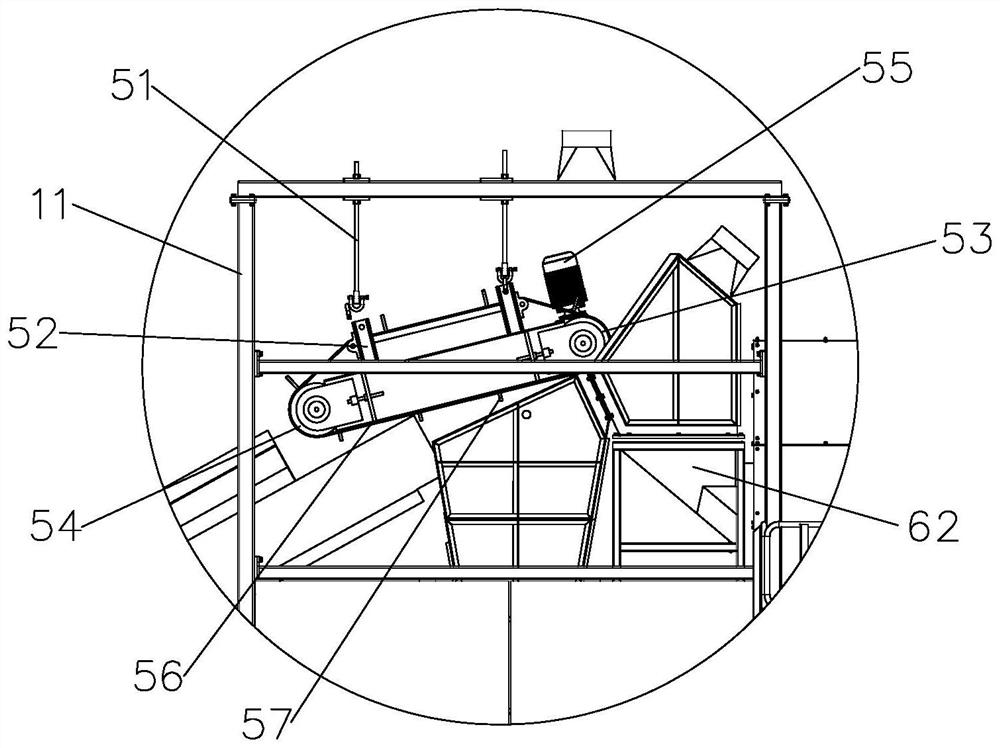

The invention provides metal packaging container crushing and cleaning equipment which comprises a first sealing room, a second sealing room and a third sealing room. The feeding chain scraper conveyor, the double-shaft shredding machine, the vibration feeder, the separation chain scraper conveyor, the roller dehydrator, the cleaning chain scraper conveyor, the first magnetic separator, the first roller cleaning machine, the crushing chain scraper conveyor, the hammer crusher, the belt conveyor, the second magnetic separator, the second roller cleaning machine and the collecting frame are connected in sequence. By arranging the machine tables which are connected in sequence, automatic production can be achieved, and the production efficiency is relatively high; a plurality of cover bodies and sealing rooms are arranged and are connected with a negative pressure fan, so that dust is not easy to drift into the air, and the air is not easy to pollute; meanwhile, the vibration feeder and the roller dehydrator are arranged, and the roller cleaning machines are arranged in front of and behind the hammer crusher respectively, so that the impurity rate of the materials is effectively reduced, fire is not prone to occurring in the crushing process, the safety is relatively good, and the quality of the recycled metal aggregate is relatively good.

Description

technical field [0001] The invention relates to a metal waste treatment equipment, in particular to a broken cleaning equipment for metal packaging containers. Background technique [0002] At present, there are products on the market that need to be packaged in metal packaging containers, such as oil barrels, tea cans, etc. After recycling such metal packaging containers, they usually need to be broken and cleaned. In the traditional recycling process of metal packaging containers, Processes such as sorting and cleaning are usually carried out independently, requiring manual transfer of materials between various stations, and the production efficiency is relatively low. [0003] In order to improve production efficiency, some metal packaging container recycling companies use conveying devices to connect the processing devices of each station in series to form an assembly-line metal packaging container crushing and cleaning equipment, which effectively improves production ef...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B09B3/35B02C21/00B02C23/14F26B5/08B03C1/02B08B3/04B08B3/02B08B7/02B08B13/00B09B101/10

CPCB09B3/00B02C21/00B02C23/14F26B5/08B03C1/02B08B3/04B08B3/02B08B7/02B08B13/00

Inventor 郭子成谢榭叶冠雄吴学斌

Owner HUANCHUANG XIAMEN TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com