Purification process of 1,2-benzisothiazolin-3-ketone

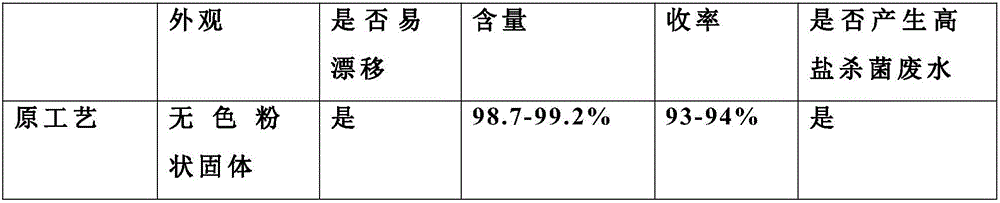

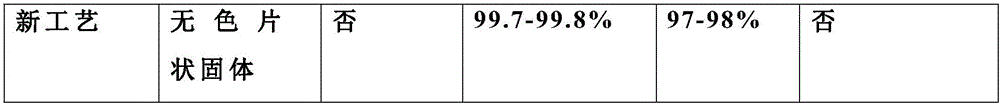

A benzisothiazoline and process technology, which is applied in the field of 1,2-benzisothiazoline-3-one purification technology, can solve the problems of allergy, easy drift, low yield and the like of staff, and achieves less allergic, The effect of not easy to drift and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045]Mix 100g of 1,2-benzisothiazolin-3-one with 297g of butyl acetate, 3g of N,N-dimethylformamide, and 0.5g of nickel chloride, then raise the temperature to 110°C, keep it warm for 2 hours, then cool down to 80°C ℃, filter, the filtrate is stirred and crystallized, the stirring speed is controlled at 20 rpm, the temperature is lowered to 0-5 ℃, 1,2-benzisothiazolin-3-one crystals are precipitated, filtered, washed with water, and dried to obtain 97.8gBIT, content 99.7%, yield 97.8%.

Embodiment 2

[0047] Mix 100g of 1,2-benzisothiazolin-3-one with 280g of xylene, 20g of N,N-diethylbenzamide, and 1.5g of copper nitrate, then heat it up to 120°C, keep it warm for 2 hours, then cool it down to 90°C , filtered, the filtrate was stirred and crystallized, the stirring speed was controlled at 20 rpm, the temperature was lowered to 0-5°C, 1,2-benzisothiazolin-3-one crystals were precipitated, filtered, washed with water, and dried to obtain 97.0g BIT with a content of 99.7 %, yield 97.0%.

Embodiment 3

[0049] Mix 100g of 1,2-benzisothiazolin-3-one with 290g of chlorobenzene, 10g of N-methylpyrrolidone, and 1g of zinc nitrate, then heat up to 120°C, keep warm for 2 hours, cool down to 85°C, filter, and the filtrate is stirred and crystallized , the stirring speed was controlled at 20 rpm, and the temperature was lowered to 0-5°C to precipitate 1,2-benzisothiazolin-3-one crystals, filtered, washed with water, and dried to obtain 96.8g of BIT, with a content of 99.8% and a yield of 96.8% .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com