Welding method of stainless steel sheet

A thin plate welding and stainless steel technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of affecting mechanical rigidity, difficulty in increasing welding speed, and over-burning of weld structure, so as to avoid over-burning of weld structure, The effect of improving the quality of arc welding and increasing the welding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

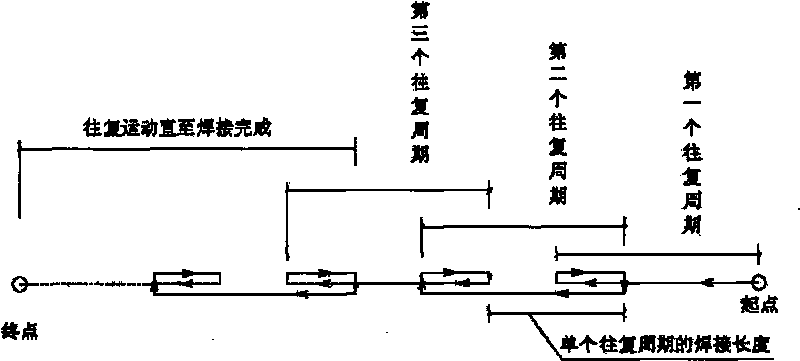

[0023] Embodiment 1, for the stainless steel car body of a rail vehicle, a linear reciprocating welding trajectory is adopted in the welding process of the thin plate corner butt weld.

[0024] Along the direction of the corner butt weld, control the torch to take such image 3 The linear reciprocating motion trajectory shown.

[0025] During the whole welding operation process, including several end-to-end reciprocating motion cycles, the same welding speed is used in each motion cycle.

[0026] In each movement cycle, the welding method is to weld forward and then backward repeatedly.

[0027] The ratio of the forward welding distance to the backward repeated welding distance is 3:1, that is, the movement of the welding spot is "three forwards and one backward".

[0028] Certain welding parameters are selected according to the shape and size of the stainless steel sheet used. Under this premise, controlling the number of reciprocating motion cycles, that is, the motion fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com