Pre-desiliconisation method for ore concentration of bauxite

A bauxite and pre-desilication technology, applied in the field of desiliconization, can solve the problems affecting the desiliconization efficiency of bauxite and eliminate aggregation, so as to improve the separation efficiency of aluminum and silicon, simplify the process flow and improve the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

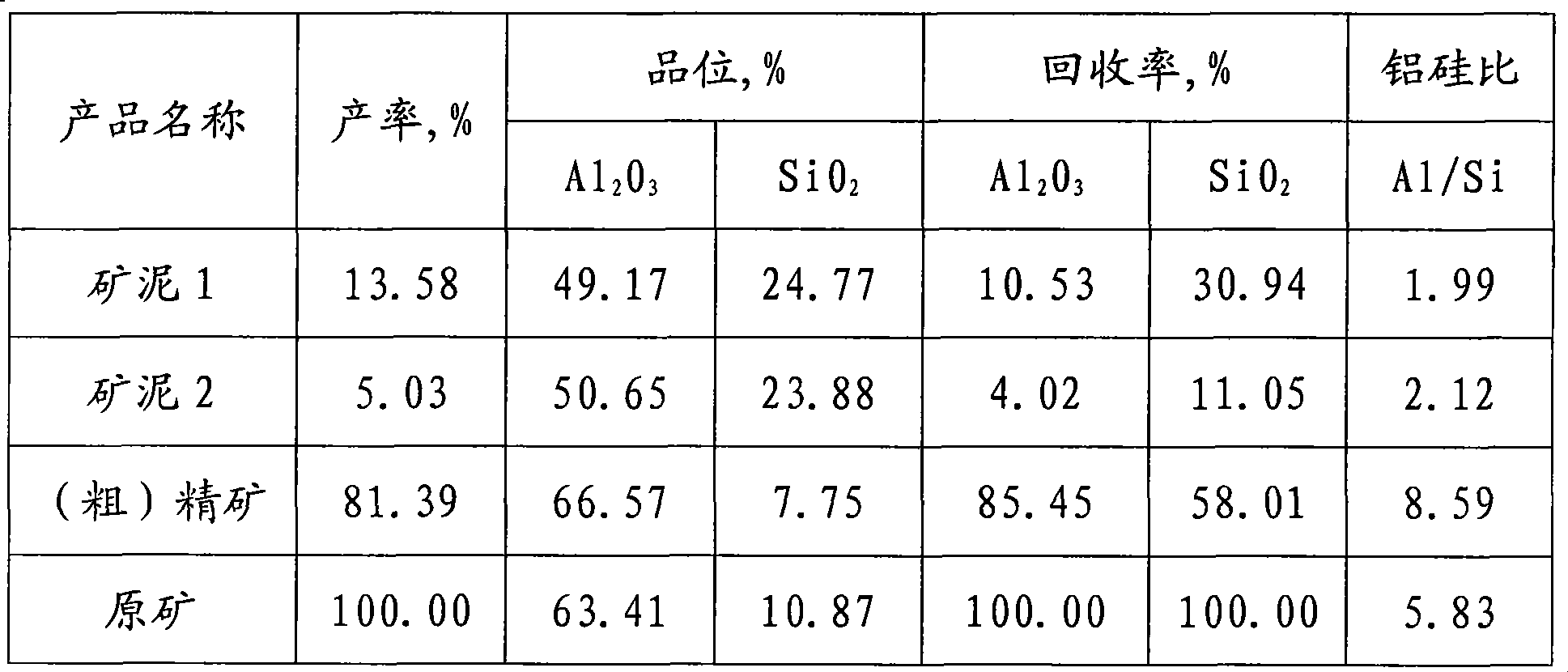

[0024] Bauxite raw ore contains Al 2 o 3 63.41%, SiO 2 is 10.87%, and the aluminum-silicon ratio (A / S) is 5.83.

[0025] Grind the raw bauxite ore, add 3kg / t of dispersant sodium carbonate during the grinding process, realize the enhanced dispersion of bauxite pulp, and obtain grinding products with a particle size of less than 0.074mm accounting for 90% of the grinding products, and feed them to the grinding Add flocculant sodium polyacrylate 10g / t to the mineral products, settle and separate after pulping, and extract the upper suspension (slime 1). Add 2 kg / t of dispersant sodium carbonate and water to the obtained sedimentation product to adjust the slurry, after vigorously stirring and scrubbing at 1000 rpm, settle and separate, and extract the upper layer suspension (sludge 2). The sedimentation product is concentrate (or coarse concentrate), and the test indicators are shown in Table 1.

[0026] The results in Table 1 show that, with the new method of the present in...

Embodiment 2

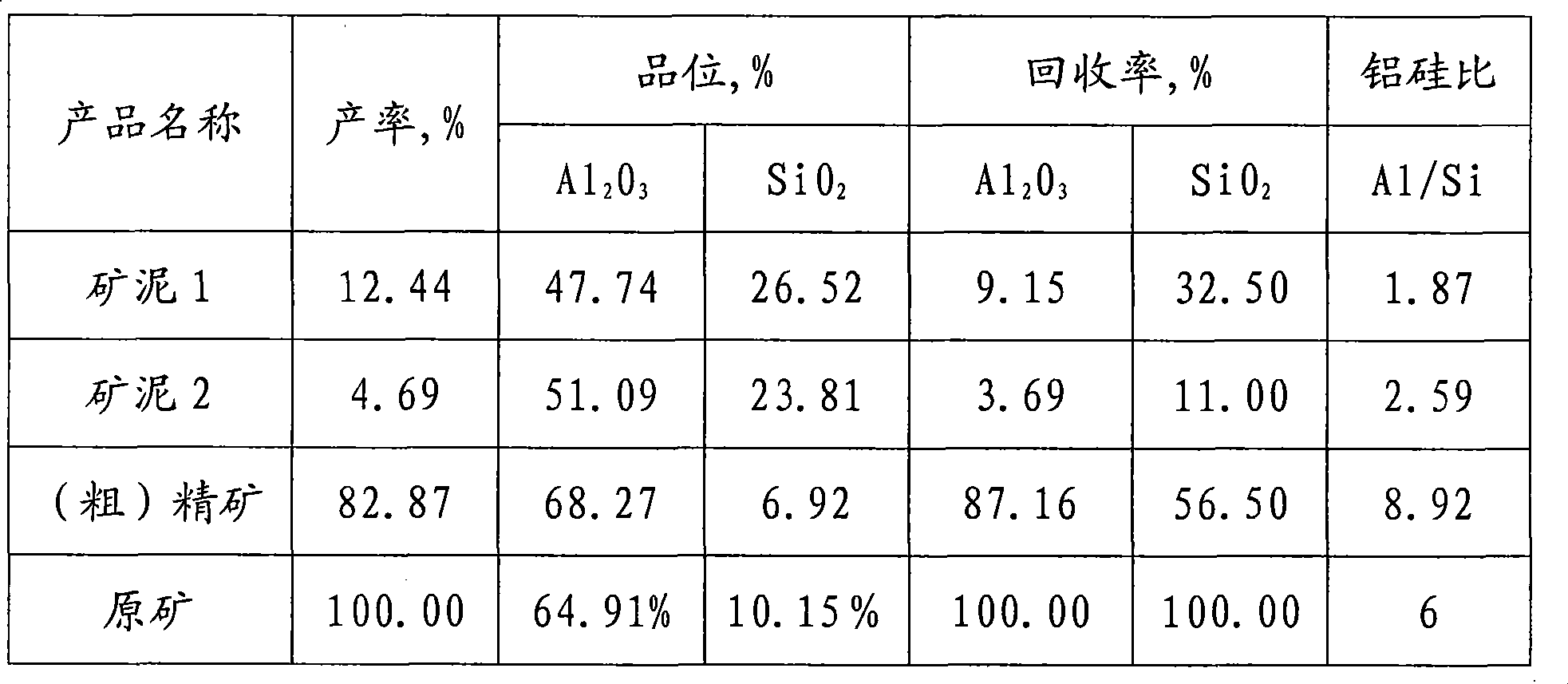

[0030] Bauxite raw ore contains Al 2 o 3 64.91%, SiO 2 is 10.15%, and the aluminum-silicon ratio (A / S) is 6.

[0031] Grinding the raw bauxite ore, adding 2kg / t sodium hexametaphosphate as a dispersant during the grinding process, to achieve enhanced dispersion of bauxite pulp, and to obtain grinding products with a particle size of less than 0.074mm accounting for 70% of the grinding products, Add flocculant carboxymethyl cellulose 2g / t to the grinding product, settling and separating after slurry adjustment, and extract the upper suspension (sludge 1). Add 1 kg / t of sodium hexametaphosphate as a dispersant and water to adjust the slurry to the obtained sedimentation product. After vigorously stirring and scrubbing at 1600 rpm, settle and separate, and extract the upper suspension (sludge 2). The sedimentation product is concentrate (or coarse concentrate), and the test indicators are shown in Table 2.

[0032] The results in Table 2 show that, with the new method of the ...

Embodiment 3

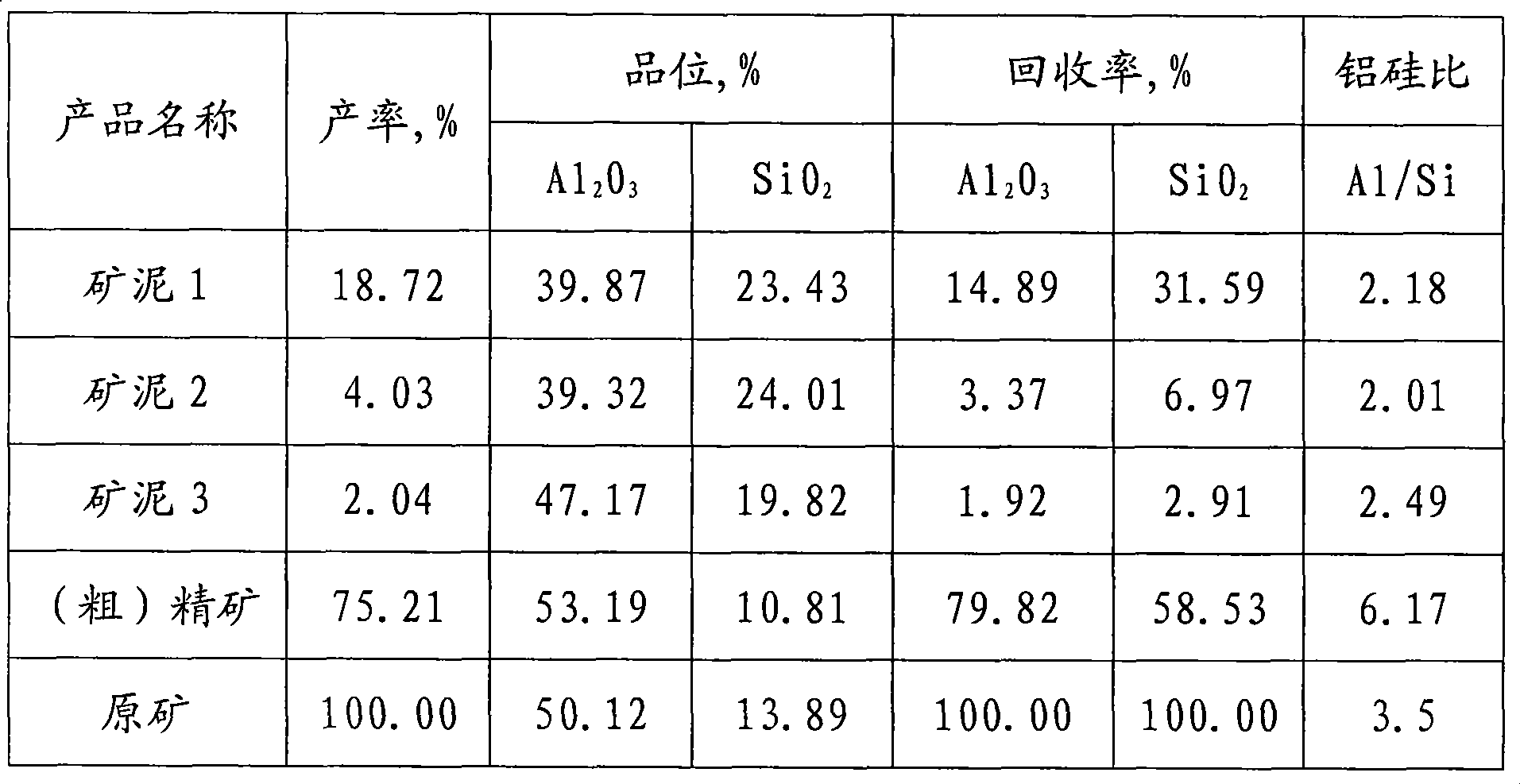

[0036] Bauxite raw ore contains Al 2 o 3 50.12%, SiO 2 It is 13.89%, and the aluminum-silicon ratio (A / S) is 3.5.

[0037] Grind the raw bauxite ore, add 7kg / t of dispersant sodium carbonate during the grinding process, realize the enhanced dispersion of bauxite slurry, and obtain the grinding product with a particle size of less than 0.074mm accounting for 55% of the grinding product, and feed it to the grinding Add flocculant sodium polyacrylate 15g / t to the mineral product, settling and separating after slurry adjustment, and extract the upper suspension (sludge 1). Add 5 kg / t of dispersant sodium carbonate and water to the obtained sedimentation product to adjust the slurry, after vigorously stirring and scrubbing at 1200 rpm, settle and separate, and extract the upper suspension (slime 2). Add 5 kg / t of dispersing agent sodium carbonate to obtain the sedimentation product, after 1200 rev / min strong stirring and scrubbing for the second time to adjust the slurry, sedime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com