A heating furnace heating bar material anti-adhesion conveying device

A conveying device and anti-adhesion technology, which is applied in the direction of conveyor control devices, conveyors, conveyor objects, etc., can solve problems that affect the stability of conveying, the work of the next process cannot be carried out smoothly, and the state of the bar cannot be stabilized. Achieve the effect of simple structure and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings.

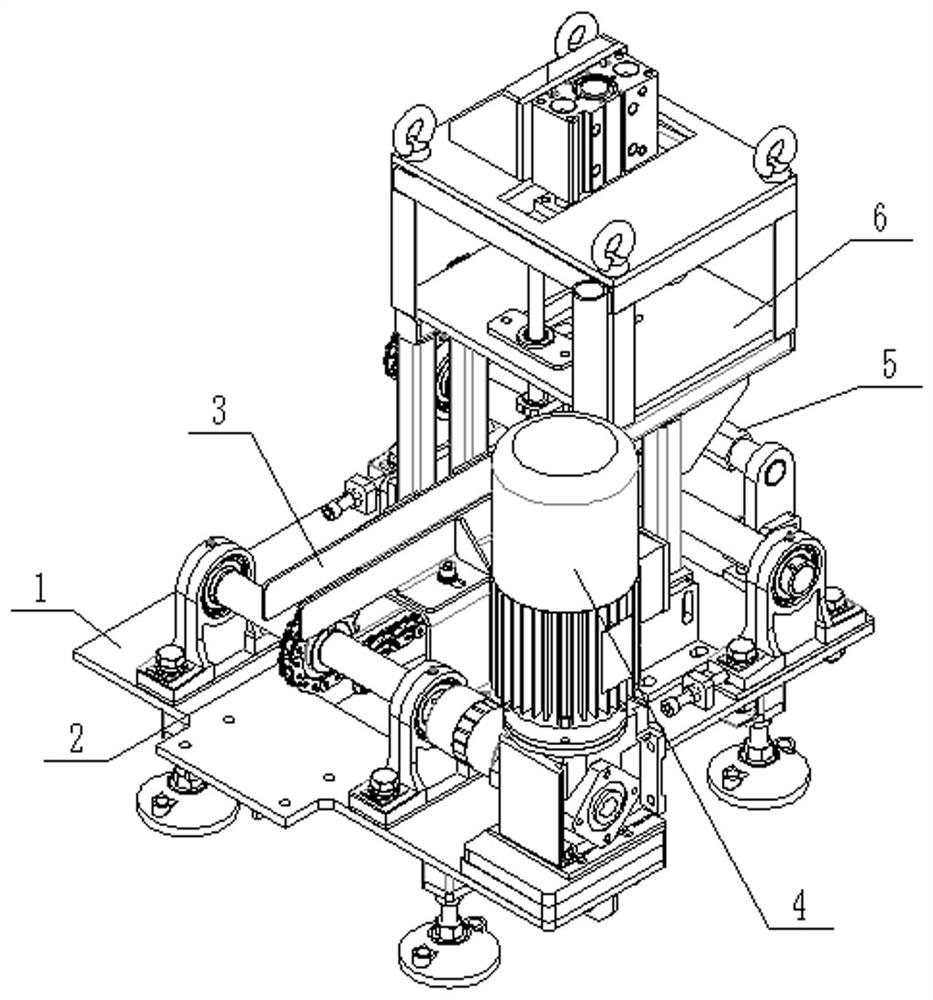

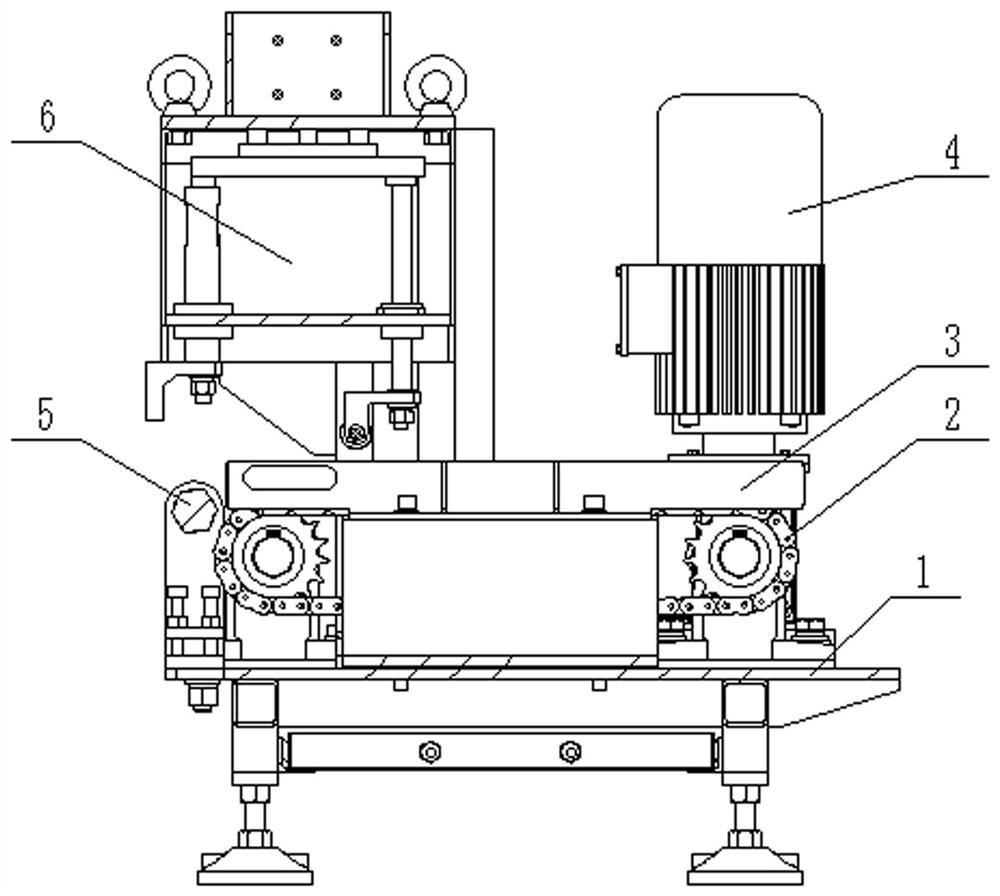

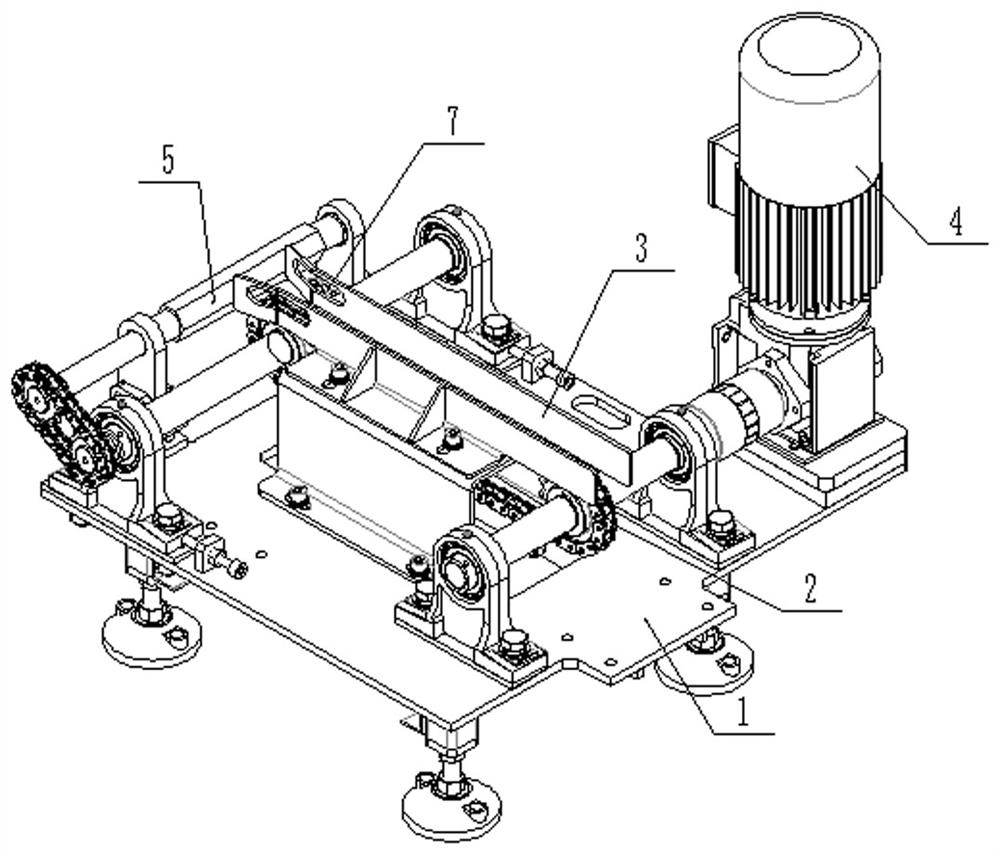

[0030] Such as Figure 1 to Figure 6 As shown, an anti-adhesion conveying device for heated bars in a heating furnace is arranged in the output direction of the bar heating furnace, and includes a base 1 and a motor 4. A conveyor chain 2 is provided above the base 1 to transport the heated bars from the heating furnace. The motor 4 Drive the conveyor chain 2 to rotate through the sprocket;

[0031] Both sides above the conveyor chain 2 are provided with conveyor baffles 3, and one end of the conveyor chain 2 in the input direction is longitudinally provided with polygonal rollers 5. Higher than the top surface of the conveying chain 2, if the bar is conveyed on the polygonal roller 5, the bar will be bumped as a whole, and the bar will be separated due to the problem of sticking together due to burr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com