Method and equipment for integrated stack gas desulfurization and dust removal of circulating fluid bed in damp dry type

A circulating fluidized bed, desulfurization and dust removal technology, which is applied in the field of flue gas purification, can solve the problems of unevenness of large-diameter desulfurization towers, the influence of desulfurization agent utilization, and large amount of discharged flue gas, and achieves compact structure, optimized distribution mode, The effect of dealing with a large amount of flue gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

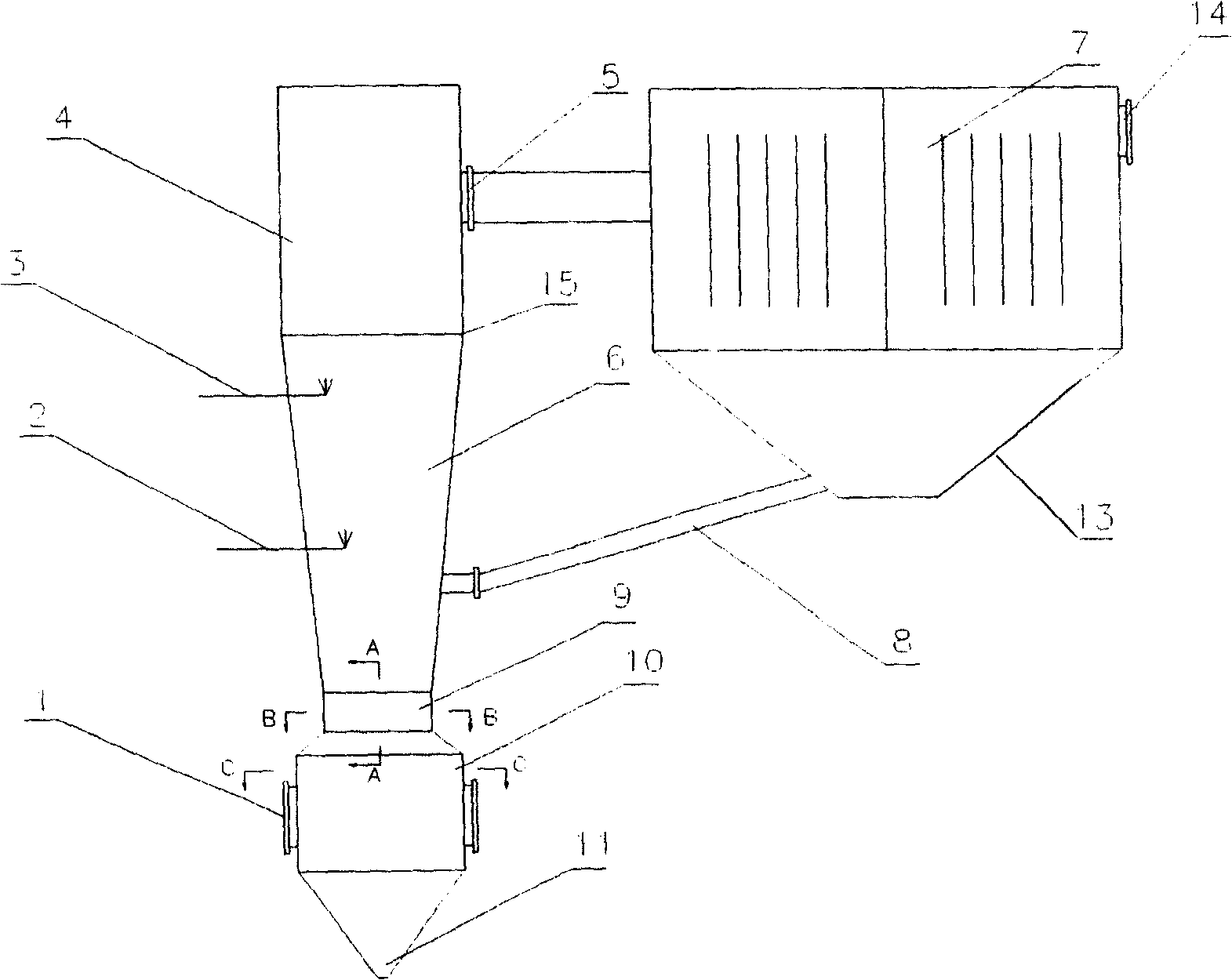

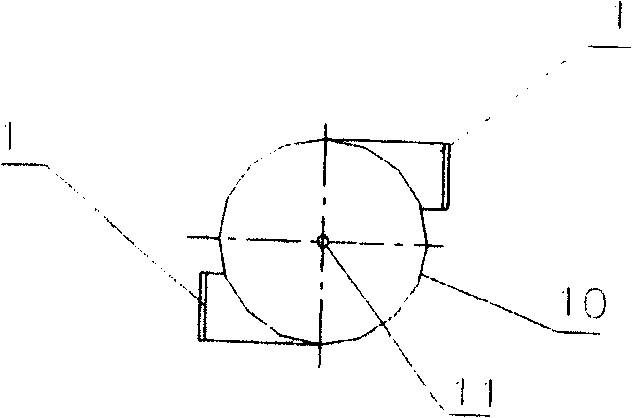

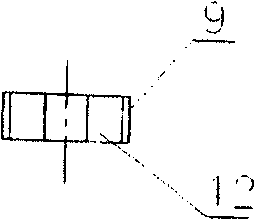

[0028] see Figure 1 to Figure 4 , The device of the present invention includes a pre-separation chamber 10 , a desulfurization tower 15 and a bag filter 7 . The desulfurization tower 15 is formed by connecting the straight cylinder section 4 and the conical cylinder section 6 , and the bottom of the conical cylinder section 6 is connected with the pre-separation chamber 10 through the provided transition section 9 . Five to nine through pipes are built in the transition section 9, and each through pipe is placed in the tube bundle 12, and the tube bundle 12 and the inner wall of the transition section 9 are welded and supported. The bottom of the pre-separation chamber 10 is provided with a conical bottom with an ash outlet 11, and its two-way sides are provided with a flue gas inlet 1 in the form of tangential rotary air intake. There are two layers of spraying mechanism 1 2 and spraying mechanism 2 3 in the cone-cylinder section 6, which can inject different flow rates of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com