Blade hole type prewhirl nozzle for prewhirl cooling system

A pre-rotating nozzle and cooling system technology, which is applied to the cooling of the engine, the cooling of the turbine/propulsion device, engine components, etc., can solve the problems of difficult processing and installation, and poor applicability of nozzle engineering, so as to achieve easy design and Machining, guarantee of acceleration and deflection performance, effect of small flow loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

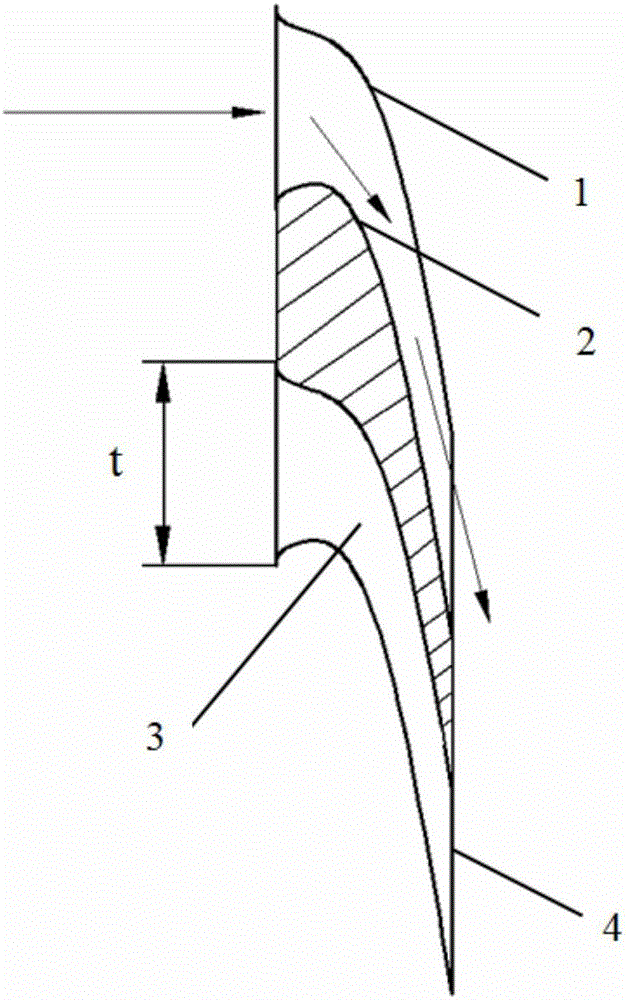

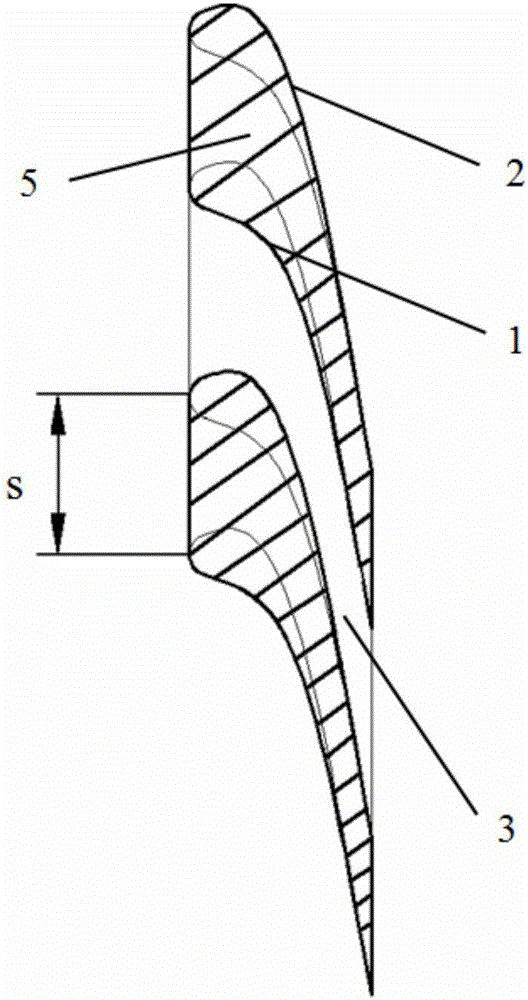

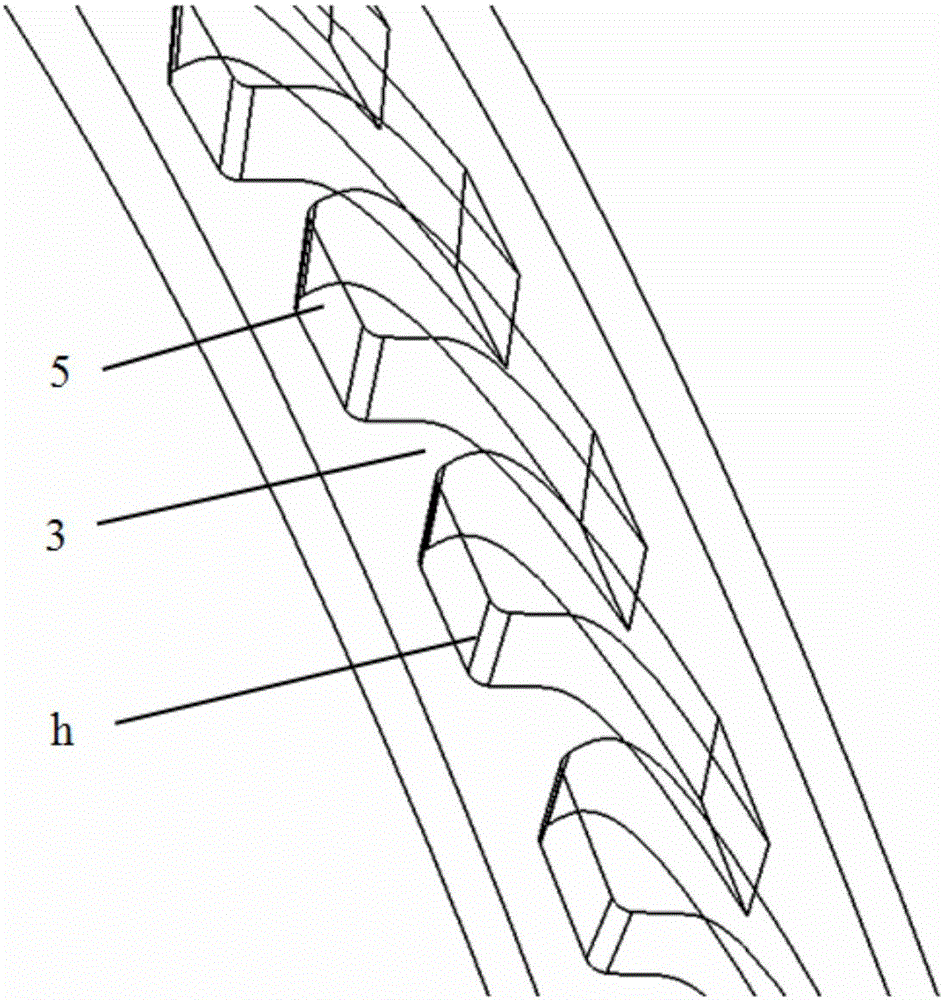

[0020] This embodiment is a leaf hole type pre-swirl nozzle used in a pre-swirl cooling system. The leaf-hole pre-swirl nozzle is a kind of oblique holes distributed on the nozzle ring at equal intervals, and its inclination angle is the pre-swirl angle.

[0021] refer to Figure 1 ~ Figure 3 , the leaf-hole pre-swirl nozzle of the pre-swirl cooling system is composed of blade pressure surface 1, blade suction surface 2, nozzle flow channel 3, pre-swirl nozzle outlet 4, and blade-shaped solid block 5; the blade pressure surface 1 and blade suction surface 2. Form oblique orifice flow passages deflected along the circumferential direction at equal intervals on the nozzle ring. The deflection surface of the nozzle flow passage 3 becomes tapered, and the minimum throat area is reached at the outlet 4 of the pre-rotation nozzle. The pre-rotation angle is 10-30°. Blade-shaped solid blocks 5 are arranged between adjacent flow channels of the leaf-hole pre-swirling nozzle, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com