Clutched super turbo control strategy

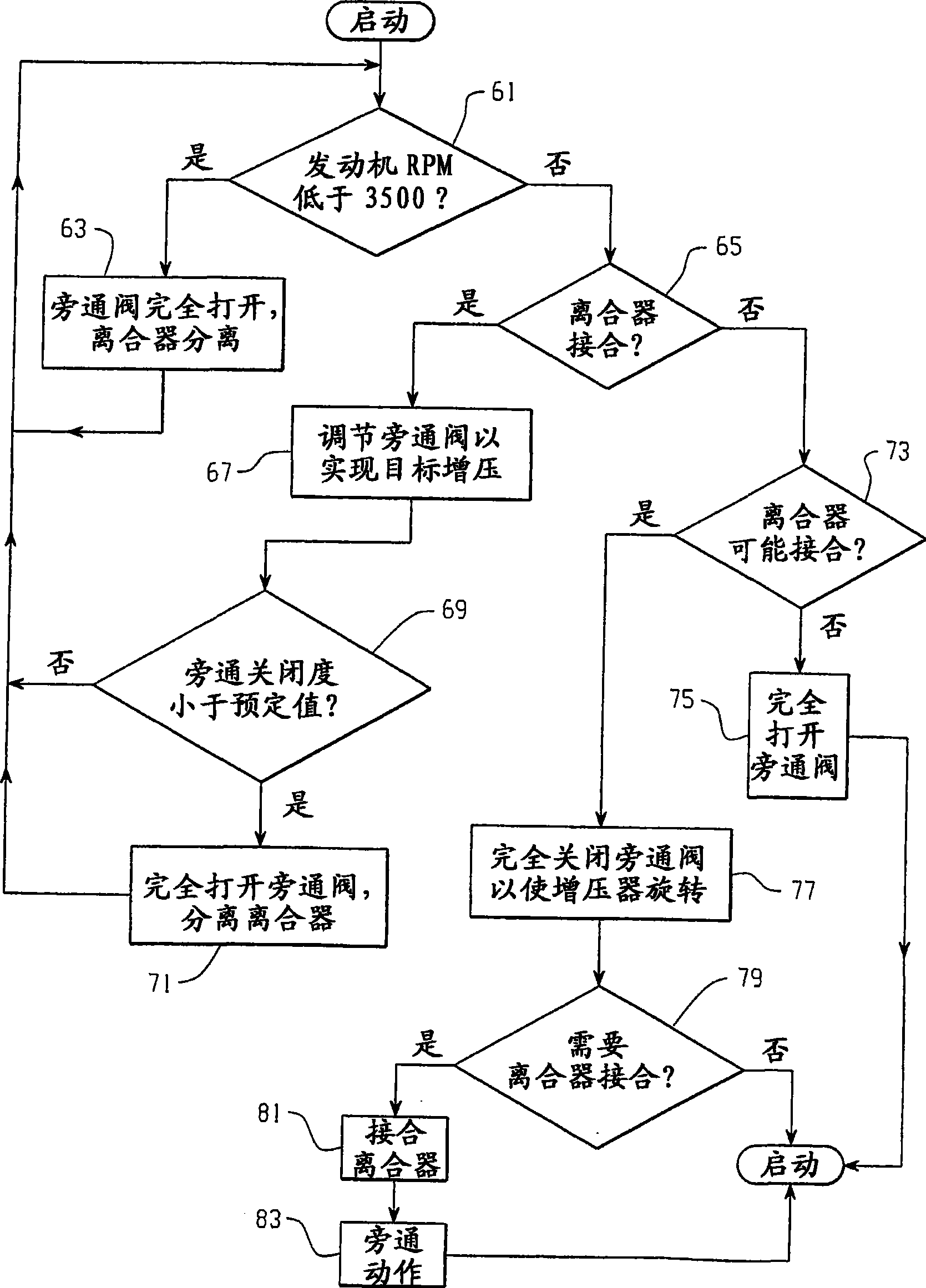

一种离合器、增压器的技术,应用在发动机控制、燃烧发动机、机器/发动机等方向,能够解决增压器接合不快、不平稳、离合器耐久性降低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

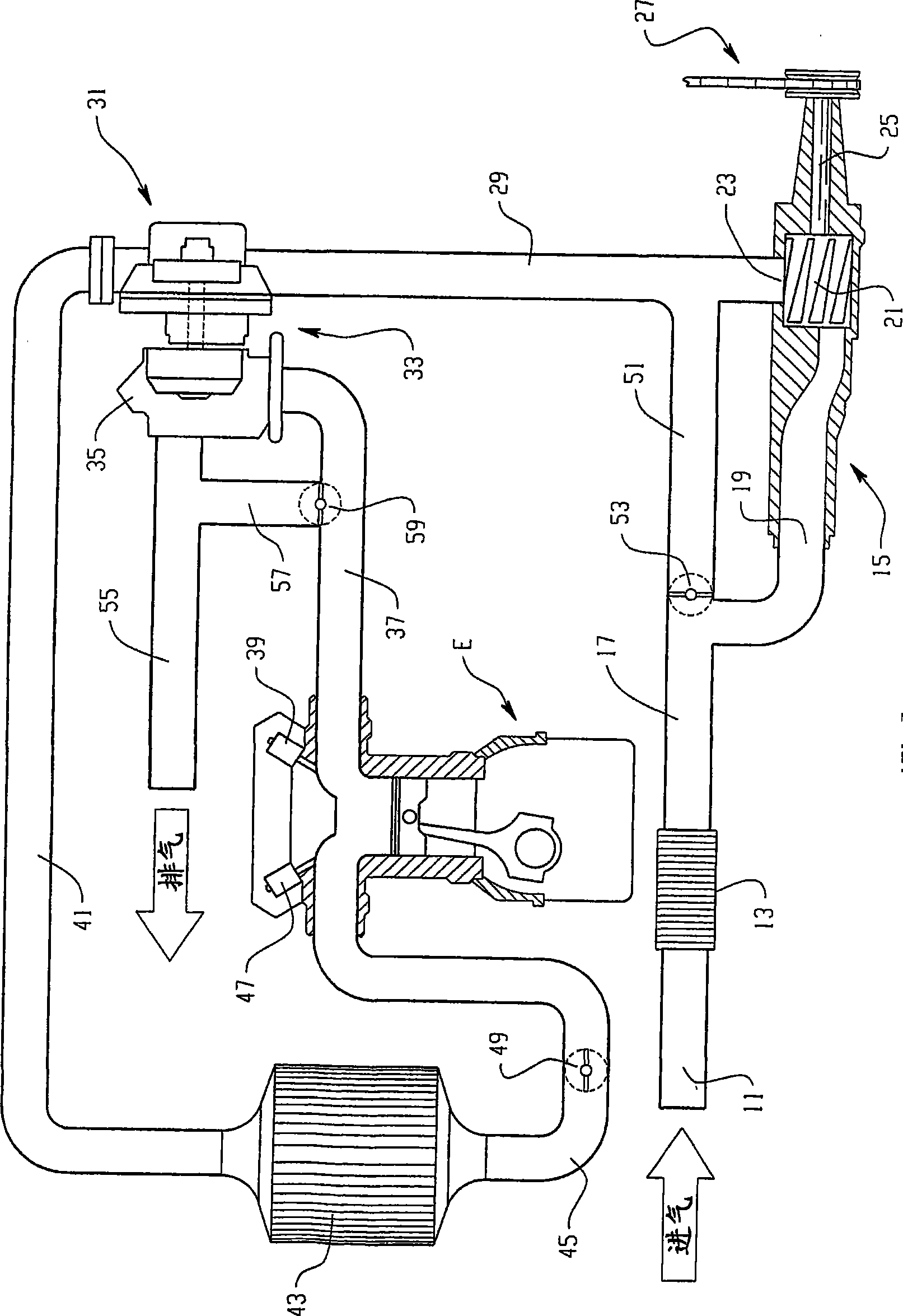

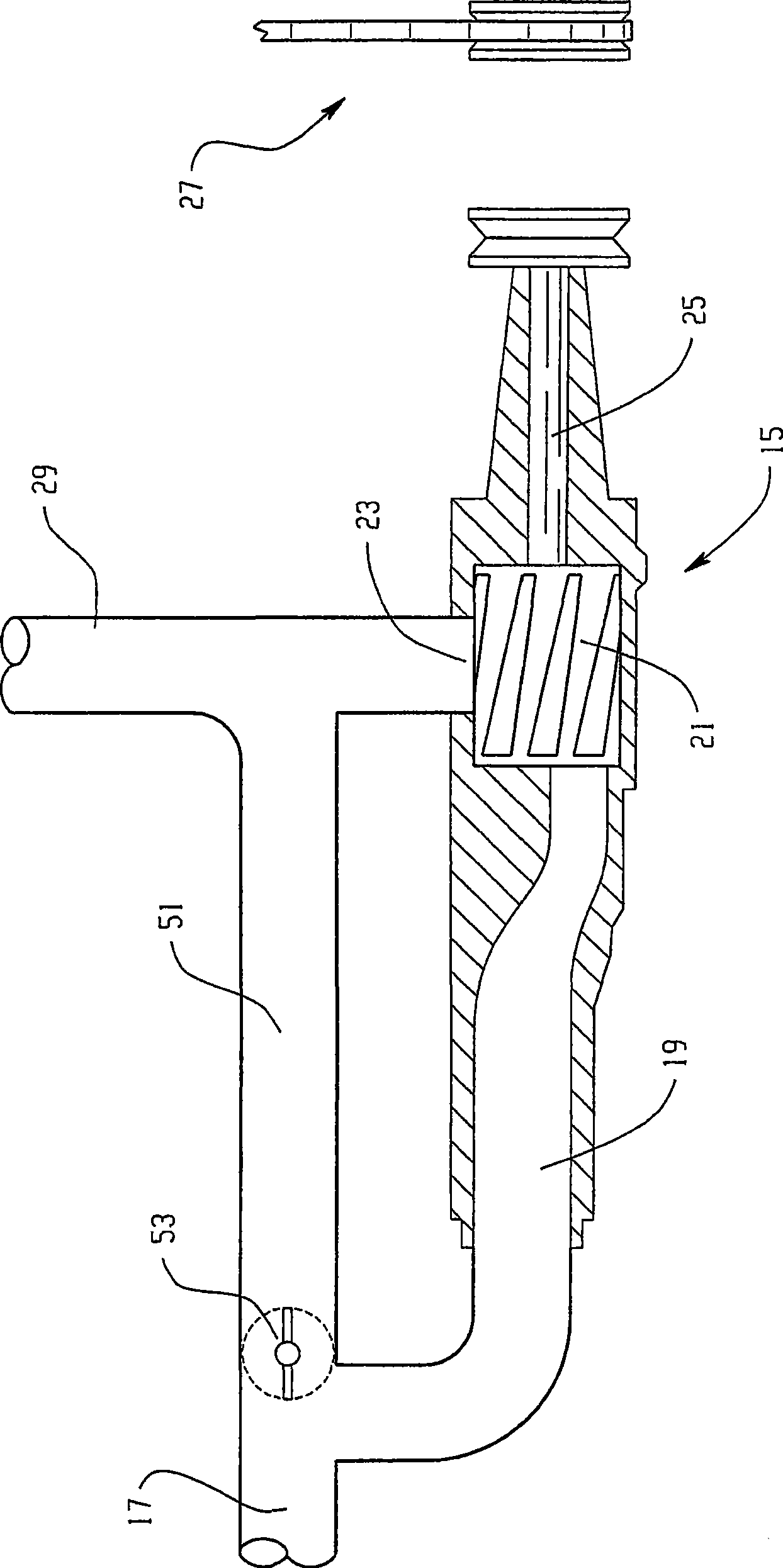

[0017] Referring now to the drawings (without limiting the invention), figure 1 A vehicle internal combustion engine is shown, including a "supercharged turbo" supercharging system, which term has been generally defined and will be explained in more detail below. Included is a conventional vehicle engine, which is generally marked with E and is simplified here with a single cylinder-piston combination. The supercharged air supplied to the combustion chamber of the engine E enters through the intake port 11 (see arrow), then flows through the air cleaner 13, and then flows through the air pipe 17 to the supercharger (generally denoted by 15), The air pipe 17 circulates incoming air to the inlet 19 of the supercharger.

[0018] The supercharger 15 usually also has a set of rotors 21, as long as the supercharger receives the mechanical driving force to its input part (probably indicated schematically as the input shaft 25), the rotor will remove a certain amount of incoming air from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com