Electric drive system based on two-gear speed changing and coordinated gear shifting control method of electric drive system

An electric drive system and motor controller technology, applied in transmission control, control device, vehicle gearbox, etc., can solve the problems of insignificant volume and weight advantage, large power loss, and easy damage to the transmission belt.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below with reference to the accompanying drawings and examples.

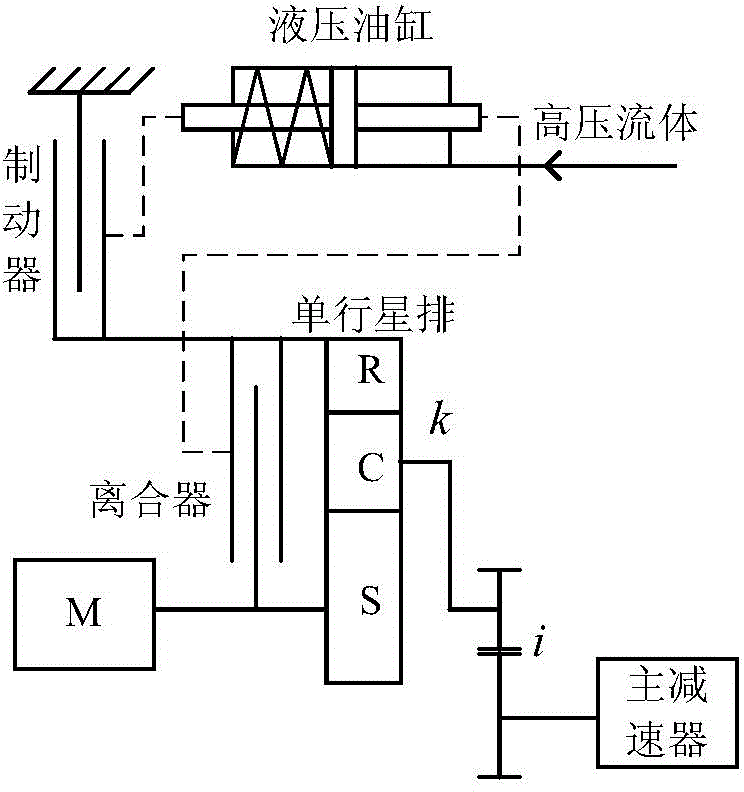

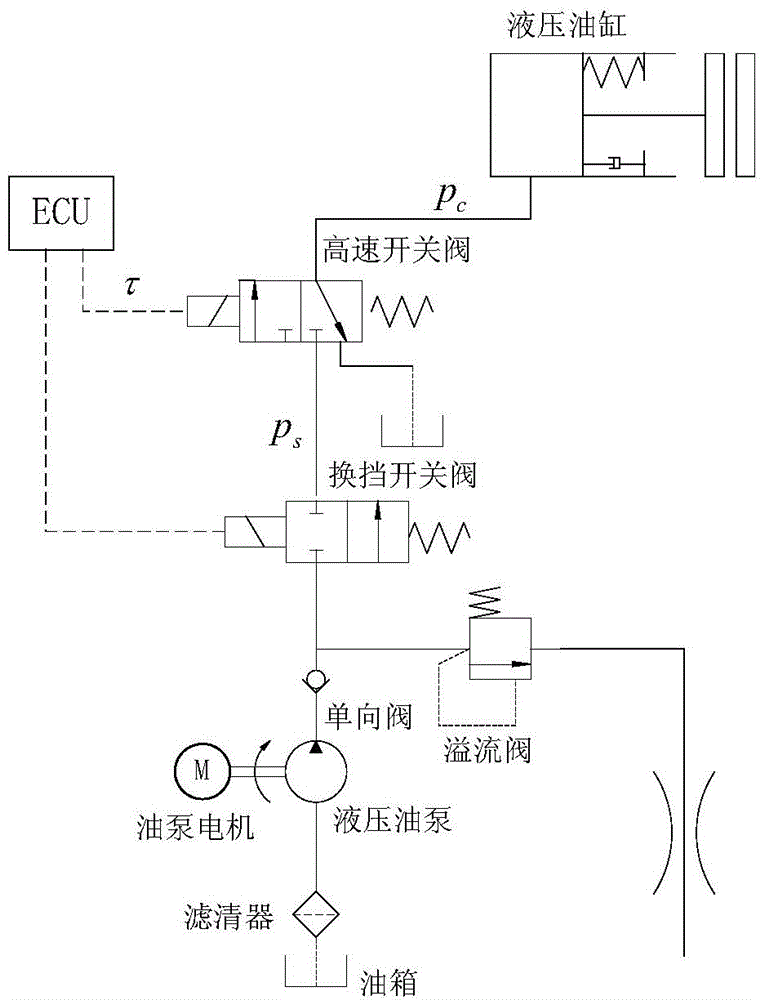

[0038] This embodiment provides an electric drive system based on two-speed transmission and its coordinated shift control method. The system adopts a planetary transmission two-speed automatic gearbox and is equipped with a wet clutch for shifting. The shifting is convenient, and the volume and weight are greatly reduced. ; During the shifting process, the motor torque and the shifting oil pressure can be adjusted synchronously to reduce the speed difference between the master and slave parts and the shifting impact when the clutch and brake are engaged or separated, and achieve smooth shifting.

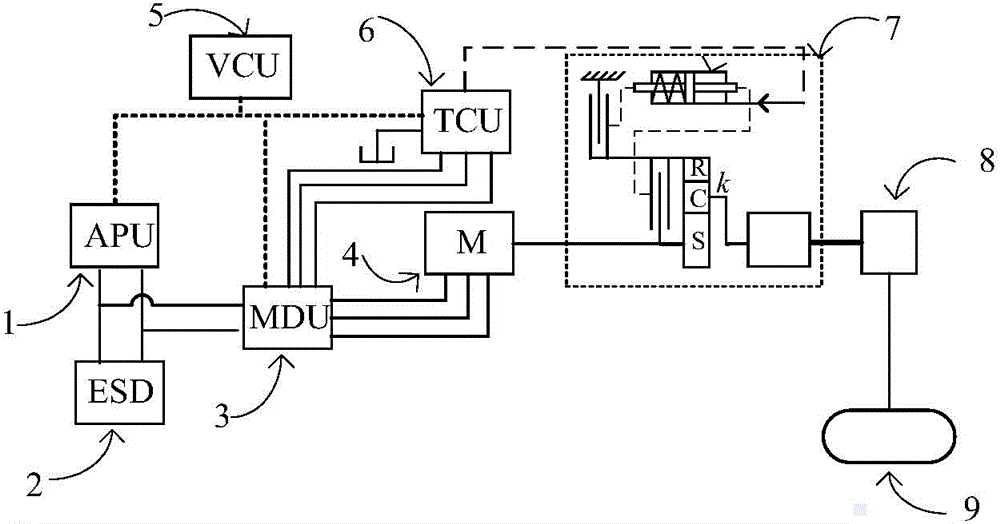

[0039] The structure of the electric drive system is as followsfigure 1 As shown, including engine-generator unit (APU) 1, electric energy storage unit (ESD) 2, motor controller (MDU) 3, drive motor (M) 4, vehicle controller (VCU) 5, shift controller (TCU ) 6, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com