Collision grinding type ultrafine smashing device

A collision device and ultra-fine grinding technology, applied in cocoa, grain processing, food science, etc., can solve problems such as uncontrollable grinding, achieve obvious grinding effect and improve grinding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

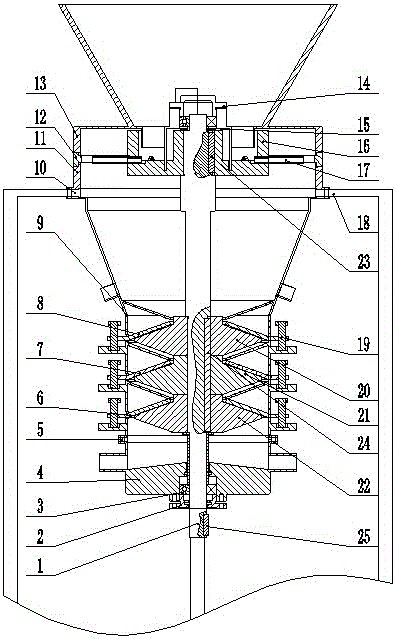

[0031] Such as Figure 1~9 As shown, a collision grinding type ultrafine crushing device includes a frame 18 and a main shaft 1. A feeding device and a collision device are fixed above the frame 18, the main shaft 1 is located on the center line of the frame 18, and the collision device It is fixed on the main shaft 1 by the key I23. The grinding device and the discharging device are arranged in sequence under the collision device. The grinding device is fixed on the main shaft 1 by the key II24. The top of the main shaft 1 is provided with a second bearing 14 and the bottom of the main shaft 1 is provided with a first Bearing 3 and the first bearing cover 2, under the main shaft 1 is connected to the motor through the key Ⅲ 25, the collision device and the grinding device are connected by the main shaft 1, and run synchronously under the action of an external motor;

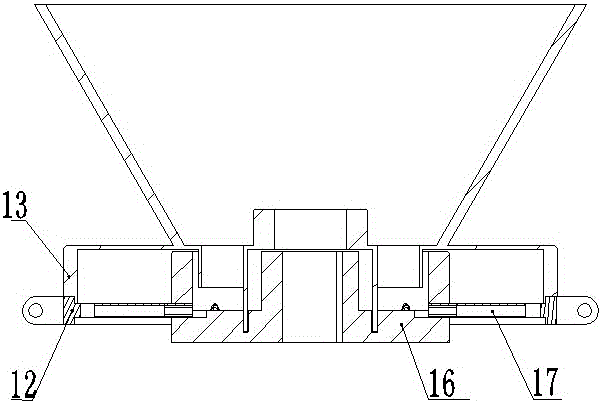

[0032] The feeding device includes a feeding port. Below the feeding port is a feeding barrel 13, a sleeve 15 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com