Pulverizer and powder production line comprising same

A technology of pulverizer and pulverizer, which is applied in the direction of solid separation, devices with reversible axial direction of swirling flow, filter screen, etc., which can solve the problems of ineffective grasping of materials and long time consumption of pulverization, so as to reduce the time consumption of pulverization , high crushing effect, and improve the effect of the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1 pulverizer

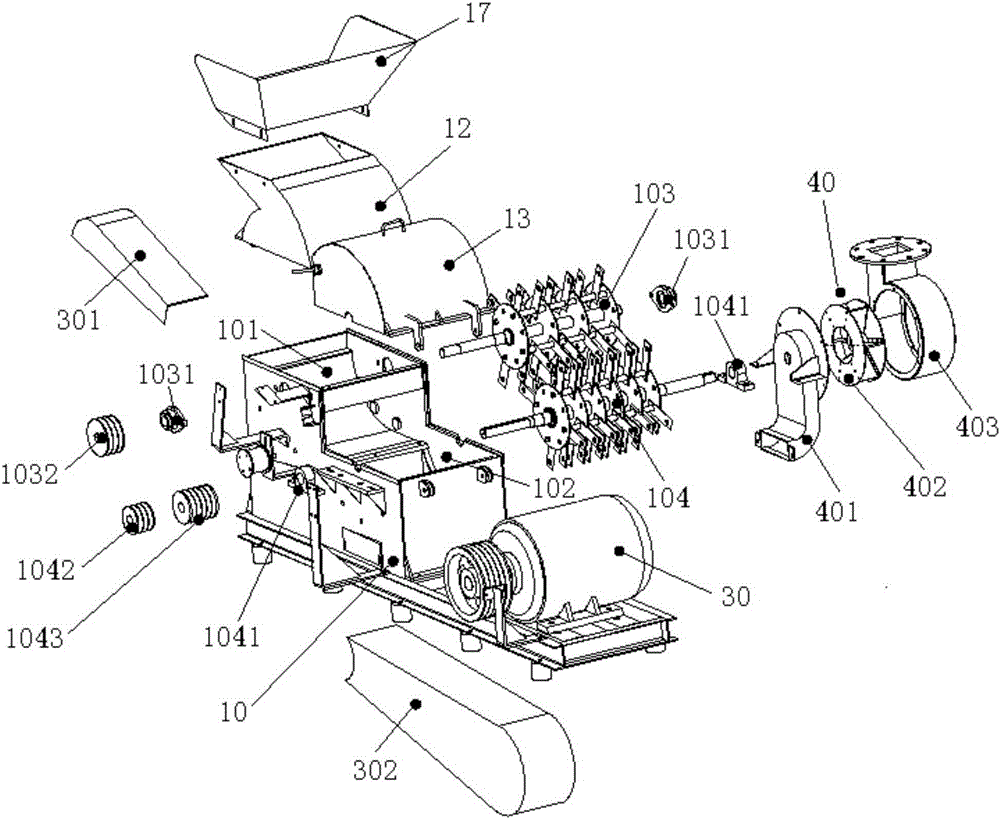

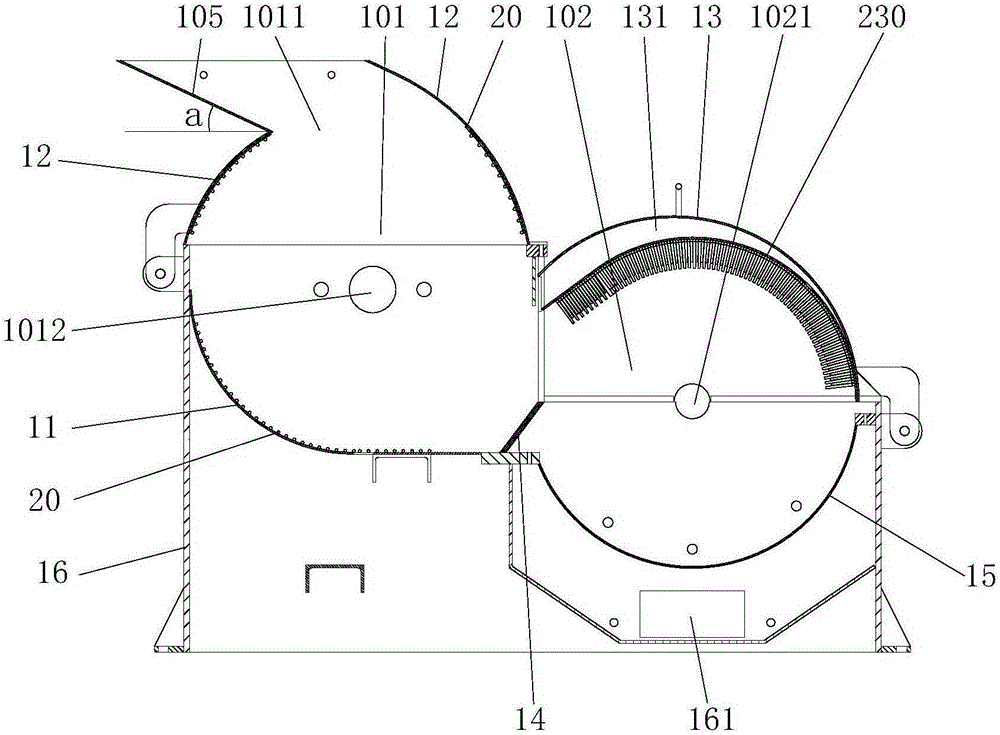

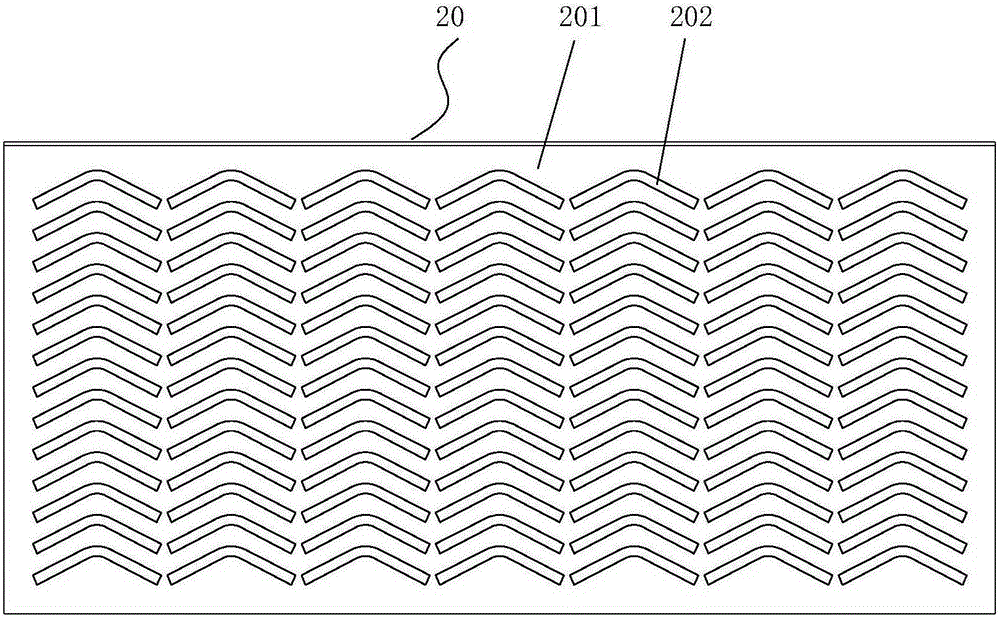

[0042] according to Figure 1 to Figure 6 As shown, the pulverizer according to Embodiment 1 of the present invention includes a secondary pulverization unit 10; Group 103 and secondary pulverizing knife group 104 and feed swash plate 105, on the top wall of the pulverizing cavity 101 that is provided with described primary pulverizing knife group 103, offer feeding port 1011, in the rotation with primary pulverizing knife group 103 The side of the inlet 1011 whose axis is parallel is connected to the swash plate 105 at an acute angle with the angle a in the horizontal direction. In order to better control the falling speed of the material, preferably, the included angle a is 20°-30°. Optimally, the included angle a is 25°. It ensures the effective grasping of materials by the crushing knife group. The central axes of the two communicating crushing chambers 101 and 102 are not on the same level, and the central axis of the crushing chamber ...

Embodiment 2

[0054] Embodiment 2 Powder production line comprising the pulverizer of Embodiment 1

[0055] according to Figure 7 As shown, the powder production line of Embodiment 2 of the present invention is illustrated, including a conveying mechanism 6, a pulverizer 1, a cyclone separator 2, an air shutoff device 3, a screening machine 4 and a filter cartridge dust collector 5.

[0056]The conveying mechanism 6 is a feeding and conveying link, which can make the materials enter the pulverizing chamber of the pulverizer continuously and uniformly. Including a conveyor belt 61, the output end of the conveyor belt 61 is set adjacent to the side of the feeding swash plate 105 of the pulverizer 1, and the conveying direction of the conveyor mechanism 6 is controlled to be consistent with the direction of the pulverizer 1. The rotation axis of the primary crushing knife set 103 is vertical, which is beneficial for the primary crushing knife set 103 to grab materials.

[0057] The discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com