Eight-axle in-phase composite rubber dicer

A synchronous combination and dicing machine technology, applied in mechanical material recovery, recycling technology, plastic recycling and other directions, can solve the problems of long process flow, large power consumption, low recycling and crushing output, etc., to shorten the work flow, save energy It has the effect of artificial and shortening the crushing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

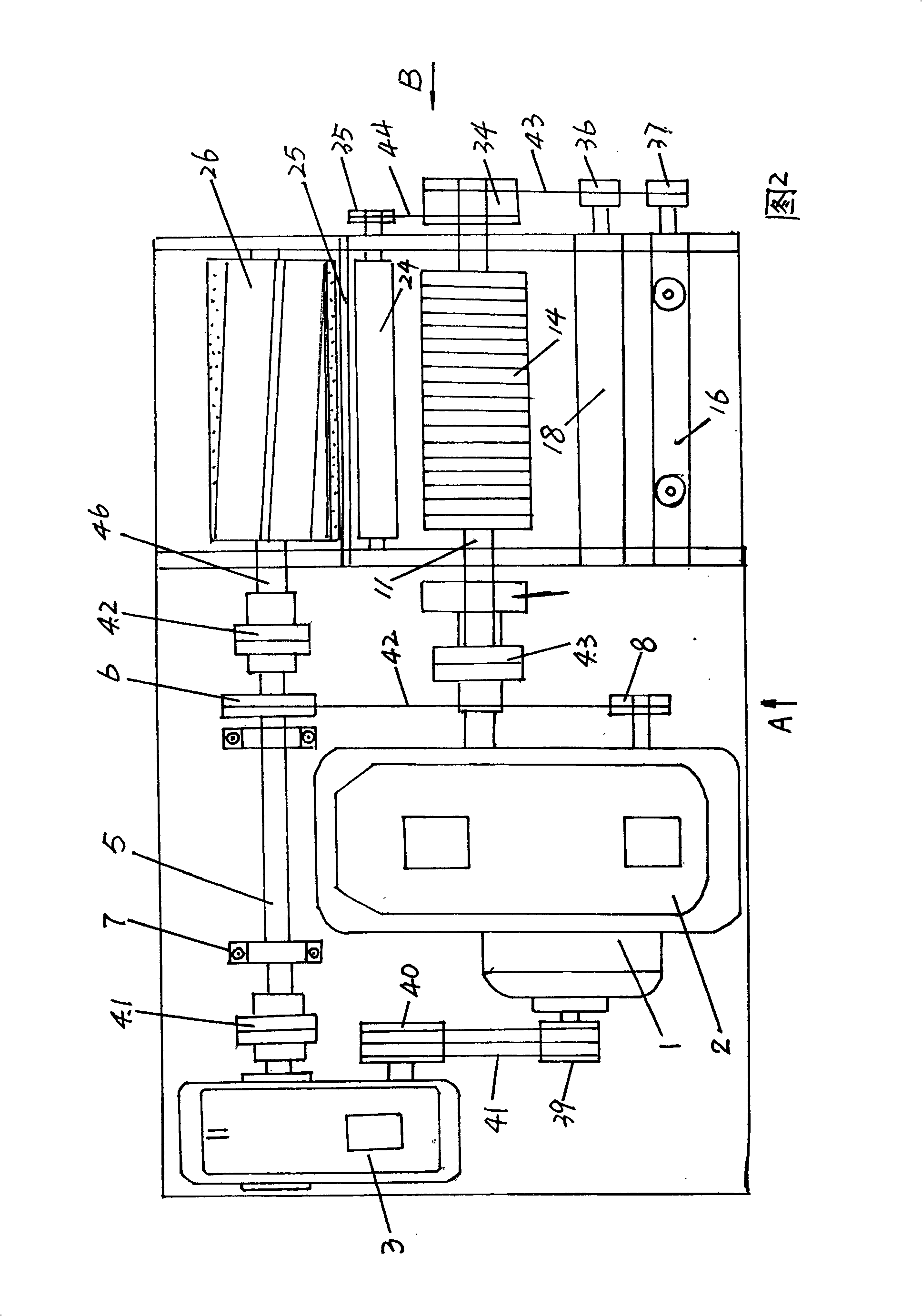

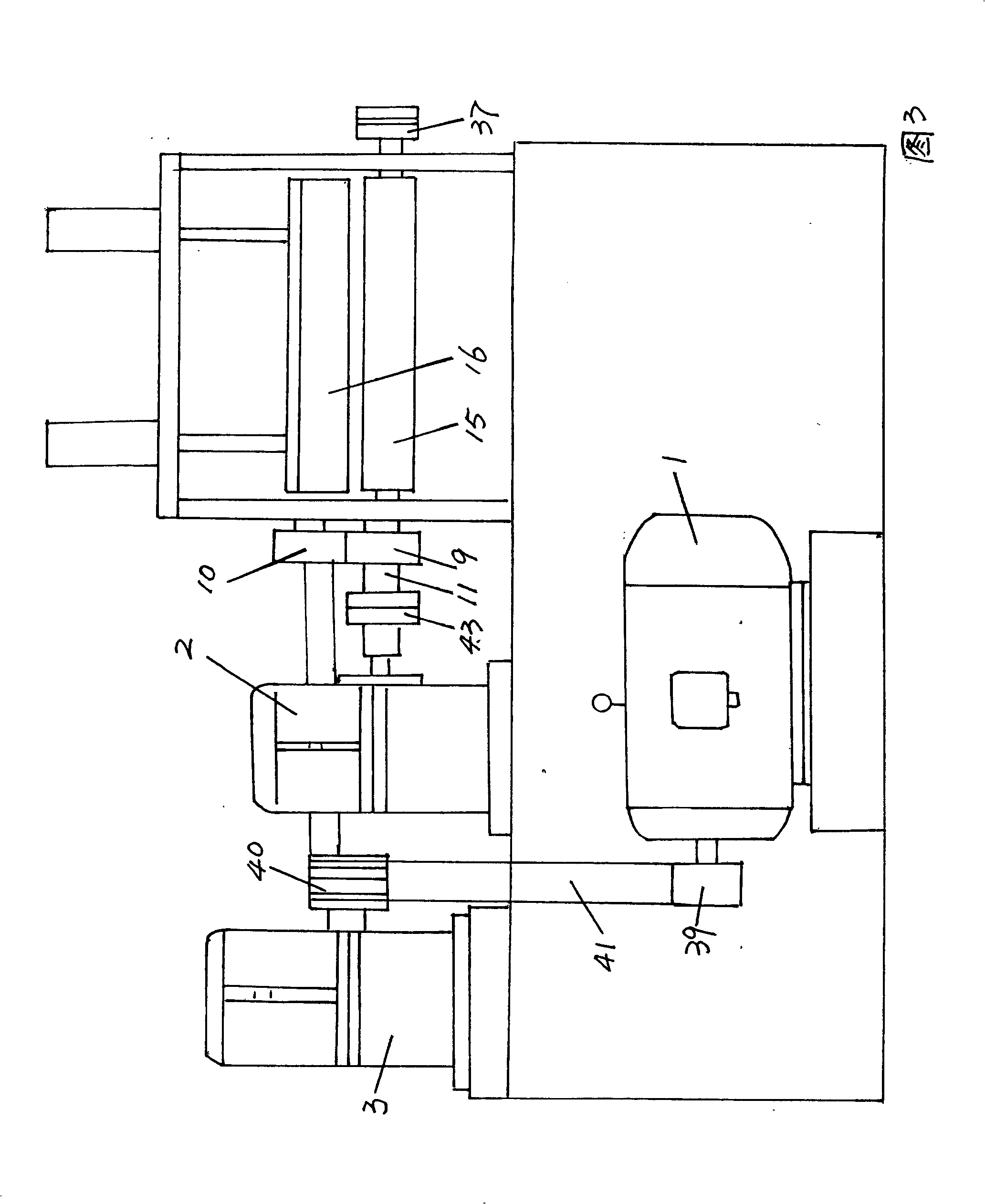

[0015] Embodiments of the present invention will be further described in conjunction with the accompanying drawings.

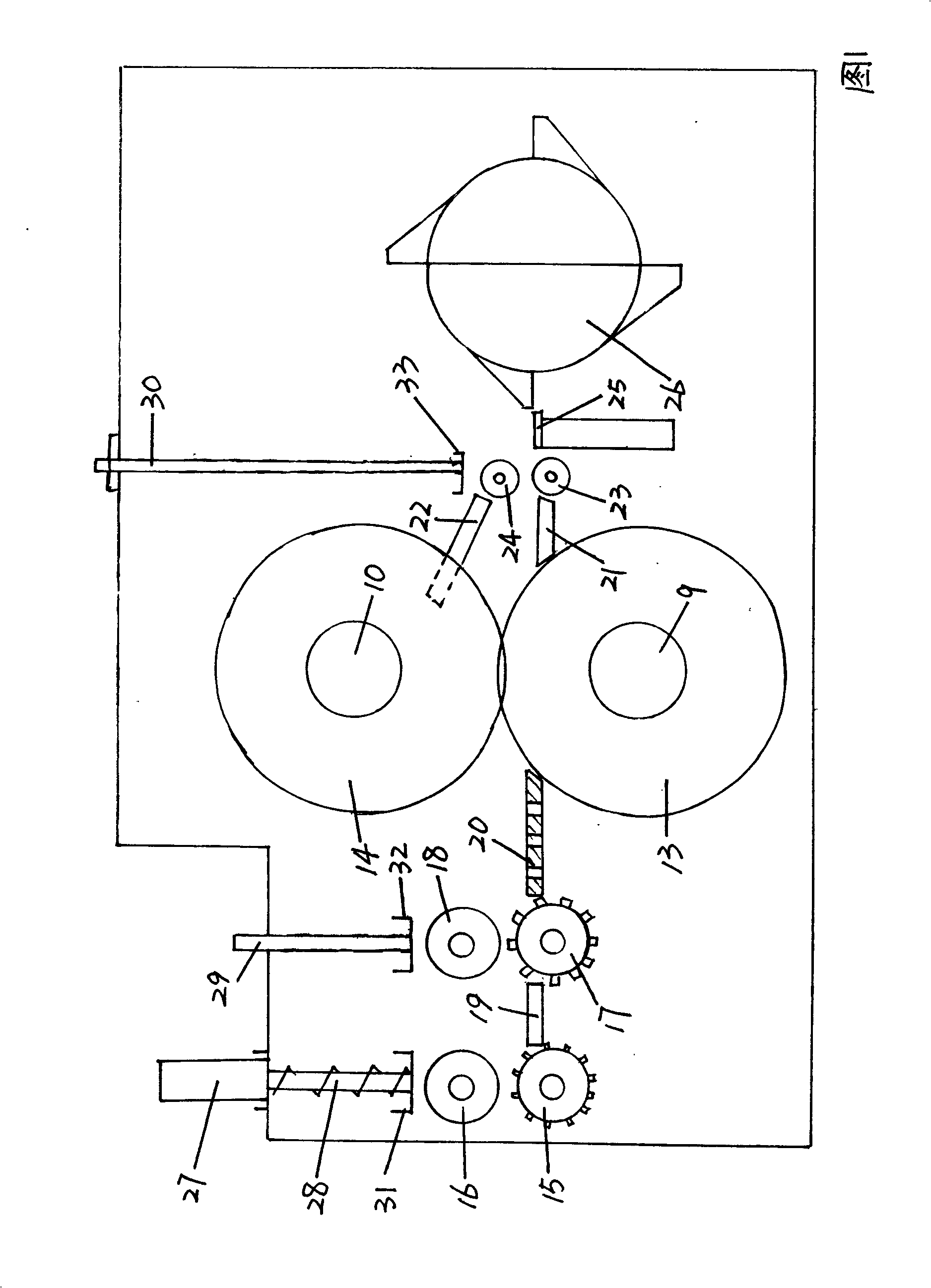

[0016] An eight-axis synchronous combination rubber cutting machine includes a feeding mechanism, a crushing mechanism, a power and transmission mechanism and a frame. Material driven roller 16, some anti-skid nails are set on the feed driving roller 15, spring rod group 28 is set above the feed driven roller 16, spring rod group 28 upper ends connect cylinder 27, and spring rod group 28 lower ends are provided with pressing plate 131.

[0017] One side of the feeding direction of the feeding drive roller 15 is provided with a material passing support plate I 19, the other end of the material passing support plate I 19 is provided with a primary cutting knife roller 17, and a primary cutting pressure roller 18 cooperating with the primary cutting knife roller 17 is arranged above the primary cutting knife roller 17 , screw mandrel I 29 is set above the primary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com