Soybean milk making method of soybean milk maker, and soybean milk maker

A soymilk machine and mechanism technology, applied in dairy products, beverage preparation devices, milk substitutes, etc., can solve the problems of poor grinding efficiency and reduced blade contact probability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

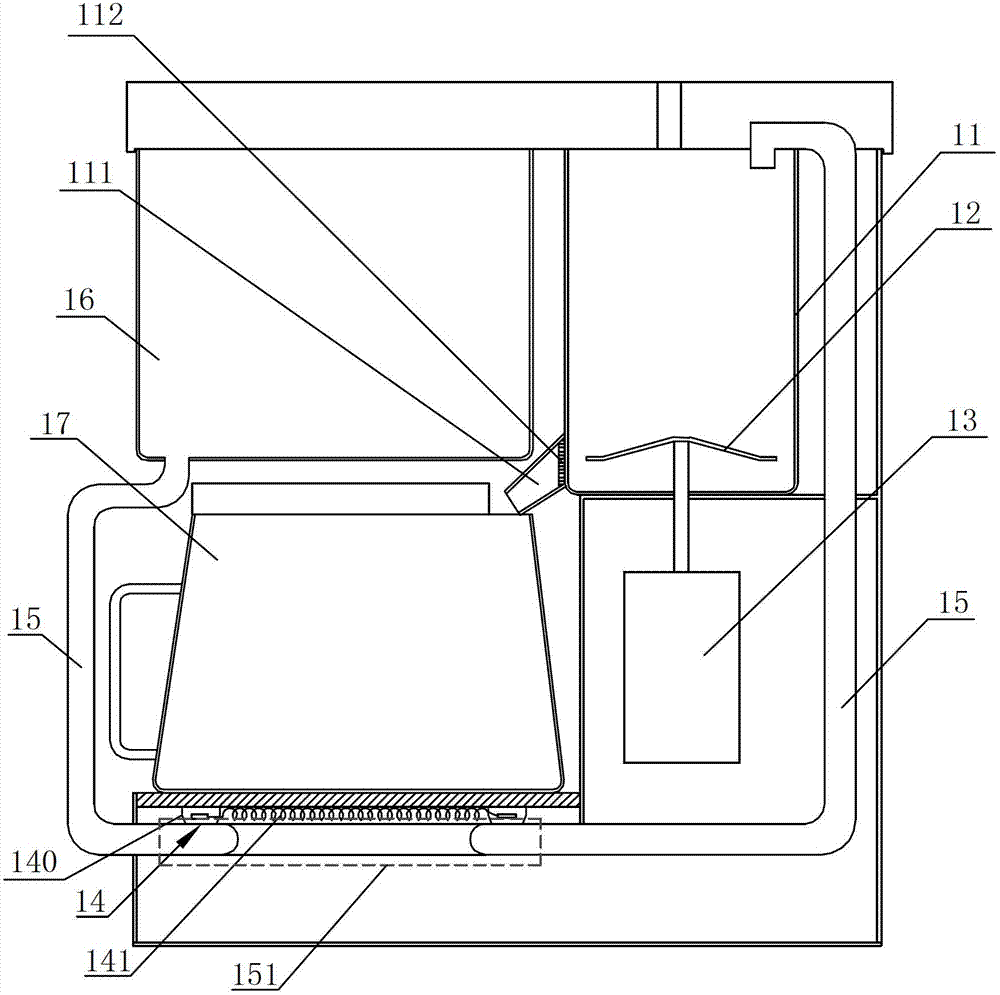

Image

Examples

no. 6 example

[0060] The sixth embodiment of the present invention is a soymilk machine pulping method. On the basis of the first embodiment, this embodiment also includes step 3 in the process of step 2:

[0061] Step 3, a step of heating the slurry in the crushing space.

[0062] Apparently, this embodiment can be combined with the fifth embodiment, so that the locations for heating are increased. Obviously, increasing the number of heating positions will inevitably help shorten the heating time, thereby increasing the pulping speed and shortening the entire pulping time.

[0063]

[0064] In the embodiment of the above-mentioned soybean milk making method, the mesh number of the filter screen is between 30 mesh and 60 mesh, such as 30, 31, 32, 33, 34, 35, 36, 37, 38, 39, 40, 41, 42, 43, 44, 45, 46, 47, 48, 49, 50, 51, 52, 53, 54, 55, 56, 57, 58, 59, 60 mesh, etc. The reason why it is within this range is that the crushed part of the material stays in the mesh of the filter, which will...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com