Environment-friendly water-based aluminum foil stamping liquid

A stamping fluid and water-based technology, applied in the field of lubricating oil, can solve the problems of unfavorable environmental protection, affecting the energy consumption of the whole machine, and consuming a lot of energy, and achieve excellent comprehensive performance, little impact on thermal conductivity, and low residual rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

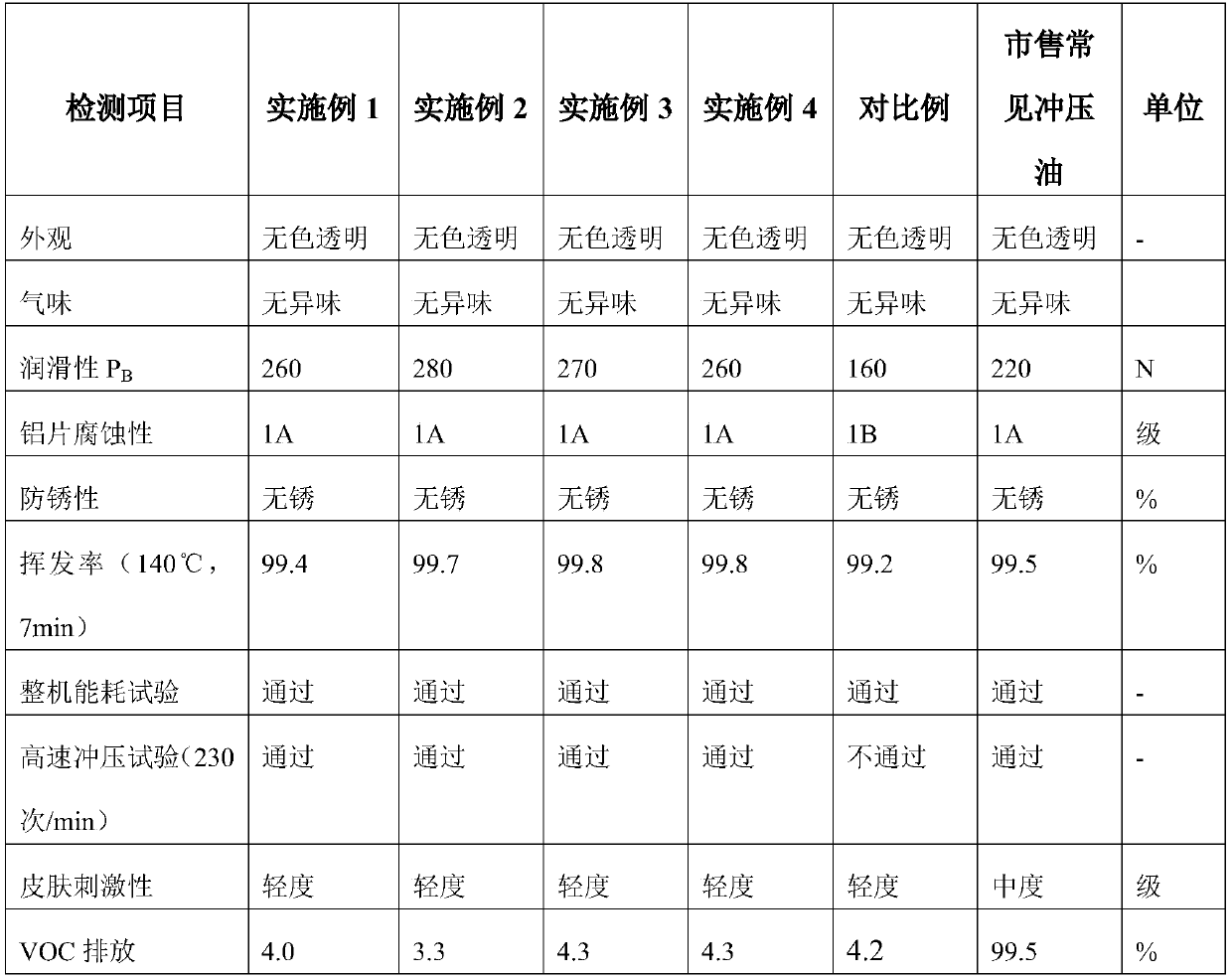

Examples

Embodiment 1

[0026] A kind of environment-friendly water base aluminum foil stamping liquid, comprises the raw material of following percentage by weight:

[0027] Lubrhophos LP700 is 0.05%, Rhodafac ASI80 is 0.001%, L190 is 0.05%, Nonidet SF-5 is 0.05%, diethylene glycol 4%, N-methyl monoethanolamine 0.4%, and distilled water is added to 100%.

Embodiment 2

[0029] A kind of environment-friendly water base aluminum foil stamping liquid, comprises the raw material of following percentage by weight:

[0030] VEG-ESTER TM GY300 is 0.05%, Korantin LUB is 0.001%, TAT730 is 0.06%, TomaKleen G-12 is 0.05%, glycerol 3%, N-methyldiethanolamine 0.3%, and supplemented with distilled water to 100%.

Embodiment 3

[0032] A kind of environment-friendly water-based aluminum foil stamping liquid, comprises the raw material of following weight percent:

[0033] Rhodafac ASI80 is 0.05%, CI2107 is 0.07%, Nonidet SF-5 is 0.05%, diethylene glycol 2%, propylene glycol 2%, diglycolamine 0.3%, and supplemented with distilled water to 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com