Method for direct electrolytic refining of crude lead

An electrolytic refining and crude lead technology is applied in the direct electrolysis of crude lead, the field of high-purity electrolytic lead and residual valuable metals, and can solve the problems of slow ion diffusion, increased impedance during electrolysis, and low conductivity of electrolyte. Achieve the effect of improving the solubility and electrical conductivity, the effect of electrolytic energy saving is remarkable, and the effect of promoting the dissolution of crude lead

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

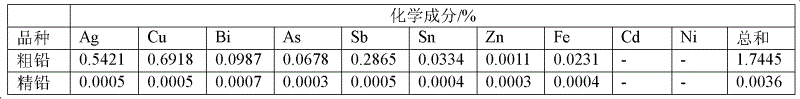

[0054] (1) get the rough lead (its composition sees Table 1) sold on the market, wherein lead content is about 98%. Melt 1kg of crude lead and cast it into a rough lead anode with stripes on the surface, with a size of 8*10*1.25 (width*height*thickness) cm 3 , the apparent density of the anode is 10.0g / cm 3 , the anode is simultaneously loaded into an anode bag made of polyvinyl chloride diaphragm material, and the thickness of the bag is 0.3mm.

[0055] (2) The size is 8*10*0.05 (width*height*thick) cm 3 The electrodeposited lead is used to make the cathode starting plate, and the distance between the anode and the cathode is controlled to be 2.0-2.2cm, so that they are placed in the electrolytic cell in parallel;

[0056] (3) The configuration concentration is 2.0mol / L HClO 4 and 0.33mol / L of Pb(ClO 4 ) 2 Mix 300ml of the solution, then add additives to make the electrolyte contain 0.55g / L boric acid, 0.3g / L chloroacetic acid, 0.2g / L acetic acid, 2.0g / L bone glue and 2....

Embodiment 2

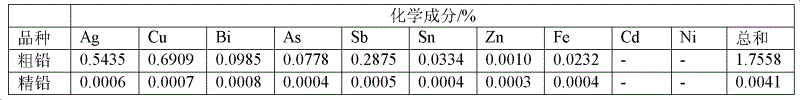

[0063] (1) get the rough lead (its composition sees Table 2) sold on the market, wherein lead content is about 98%. Melt 1kg of rough lead and cast it into a rough lead anode with stripes, the size is 8*10*1.25 (width*height*thick) cm 3 , the apparent density of the anode is 10.0g / cm 3 , the anode is simultaneously loaded into an anode bag made of polyethylene grafted film material, and the thickness of the bag is 0.05mm.

[0064] (2) The size is 8*10*0.05 (width*height*thick) cm 3 The electrodeposited lead is used to make the cathode starting plate, and the distance between the anode and the cathode is controlled to be 2.0-2.2cm, so that they are placed in the electrolytic cell in parallel;

[0065] (3) The configuration concentration is 2.2mol / L HClO 4 and 0.32mol / L of Pb(ClO 4 ) 2 Mix 300ml of the solution, then add additives, so that the electrolyte contains 0.05g / L sodium tripolyphosphate, 0.2g / L chloroacetic acid, 0.2g / L acetic acid, 1.5g / L bone glue and 2.5g / L lign...

Embodiment 3

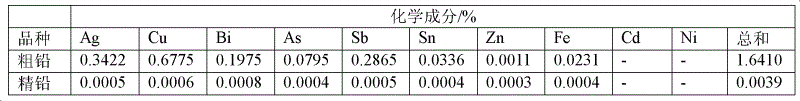

[0072] (1) get the rough lead (its composition sees Table 3) sold on the market, wherein lead content is about 98%. Melt 1kg of rough lead and cast it into a rough lead anode with stripes, the size is 8*10*1.15 (width*height*thick) cm 3 , the apparent density of the anode is 10.9g / cm 3 , the anode is simultaneously loaded into an anode bag made of polyethylene grafted film material, and the thickness of the bag is 0.05mm.

[0073] (2) The size is 8*10*0.05 (width*height*thick) cm 3 The electrodeposited lead is used to make the cathode starting plate, and the distance between the anode and the cathode is controlled to be 0.9-1.1cm, so that they are placed in the electrolytic cell in parallel;

[0074] (3) The configuration concentration is 2.2mol / L HClO 4 and 0.3mol / L of Pb(ClO 4 ) 2 Mix 300ml of the solution, then add additives, so that the electrolyte contains 0.10g / L sodium pyrophosphate, 0.2g / L chloroacetic acid, 0.2g / L acetic acid, 2.0g / L bone glue and 2.5g / L sodium l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com