Method for separating and extracting platinum with purity of 99.95% from gold-palladium-platinum-containing alloy

An alloy, palladium-platinum technology, applied in the field of separating and purifying 99.95% platinum, can solve the problems of long refining cycle, cumbersome process, low direct yield, etc., and achieve the effect of short process, guaranteed impurity removal effect, and low time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

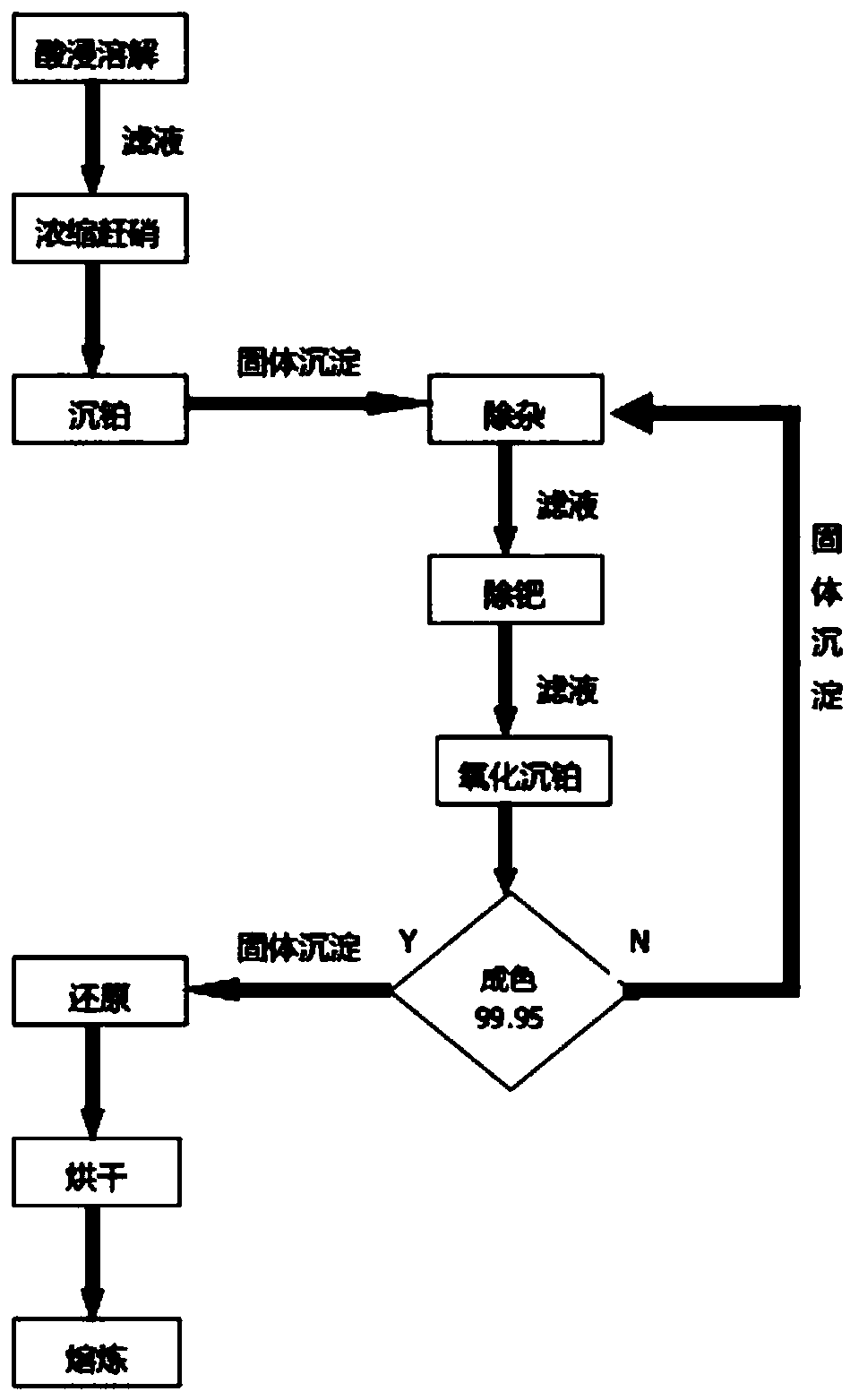

[0032] Such as figure 1 As shown, a method for separating and purifying 99.95% platinum from gold-containing palladium-platinum alloy comprises the following steps:

[0033] (1) Acid leaching and dissolving: soak the alloy containing gold, palladium and platinum in aqua regia at 95°C for 90 minutes, cool and filter. ;

[0034] (2) Concentrate and catch up with nitrate: heat and concentrate the filtrate of step (1) to 1 / 2 of the original volume in a reactor; within the temperature range of 100°C, add concentrated hydrochloric acid and heat until no reddish-brown gas is produced, stop heating, Cool to 20°C;

[0035] (3) Precipitating platinum: add the solution of step (2) into ammonium chloride in proportion to 6% of the solution mass to precipitate platinum, stir for 60min, keep the stirring speed at 2.0r / s, let stand and cool to 25°C, Filter the platinum yellow, and wash the platinum yellow with a 17% ammonium chloride solution at a temperature of 30°C until the filtrate is...

Embodiment 2

[0042] Such as figure 1 As shown, a method for separating and purifying 99.95% platinum from gold-containing palladium-platinum alloy comprises the following steps:

[0043] (1) Acid leaching and dissolving: Soak the alloy containing gold, palladium and platinum in aqua regia at 100°C for 60 minutes, cool and filter, and the ratio of gold, palladium and platinum alloy to aqua regia is 1:4~6 (g / mL) ;

[0044] (2) Concentrate and catch up with nitrate: heat and concentrate the filtrate of step (1) in a reactor to 1 / 2 of the original volume; within the temperature range of 95°C, add concentrated hydrochloric acid and heat until no reddish-brown gas is produced, stop heating, Cool to 30°C;

[0045] (3) Precipitate platinum: add ammonium chloride to the solution of step (2) according to the proportion of 8% of the solution mass to precipitate platinum, stir for 30min, keep the stirring speed at 2.0r / s, let stand and cool to 25°C, Filter the platinum yellow, wash the platinum yel...

Embodiment 3

[0052] Such as figure 1 As shown, a method for separating and purifying 99.95% platinum from gold-containing palladium-platinum alloy comprises the following steps:

[0053] (1) Acid leaching and dissolving: Soak the alloy containing gold, palladium and platinum in aqua regia at 70°C for 70 minutes, cool and filter, and the ratio of gold, palladium and platinum alloy to aqua regia is 1:4~6 (g / mL) ;

[0054] (2) Concentrate and catch up with nitrate: heat and concentrate the filtrate of step (1) to 1 / 2 of the original volume in a reactor; within the temperature range of 98°C, add concentrated hydrochloric acid and heat until no reddish-brown gas is produced, stop heating, Cool to 25°C;

[0055] (3) Precipitate platinum: add ammonium chloride to the solution of step (2) according to the proportion of 7% of the solution mass to precipitate platinum, stir for 45min, keep the stirring speed at 2.0r / s, let stand and cool to 25°C, Filter the platinum yellow, and wash the platinum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com