Method of passivating trypsin inhibitor in soybean milk by means of hydrodynamic cavitation technology

A technology of trypsin inhibition and hydrodynamic cavitation, applied in the application, dairy products, milk substitutes, etc., can solve the problems of affecting the nutritional value and processing performance of food, changing the physical and chemical properties of nutritional components, and high cost of enzymatic hydrolysis inactivation. Low residual rate, less nutrient loss, and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Embodiment 1: a kind of method utilizing hydrodynamic cavitation technology passivation trypsin inhibitor in soya-bean milk, comprises the following steps:

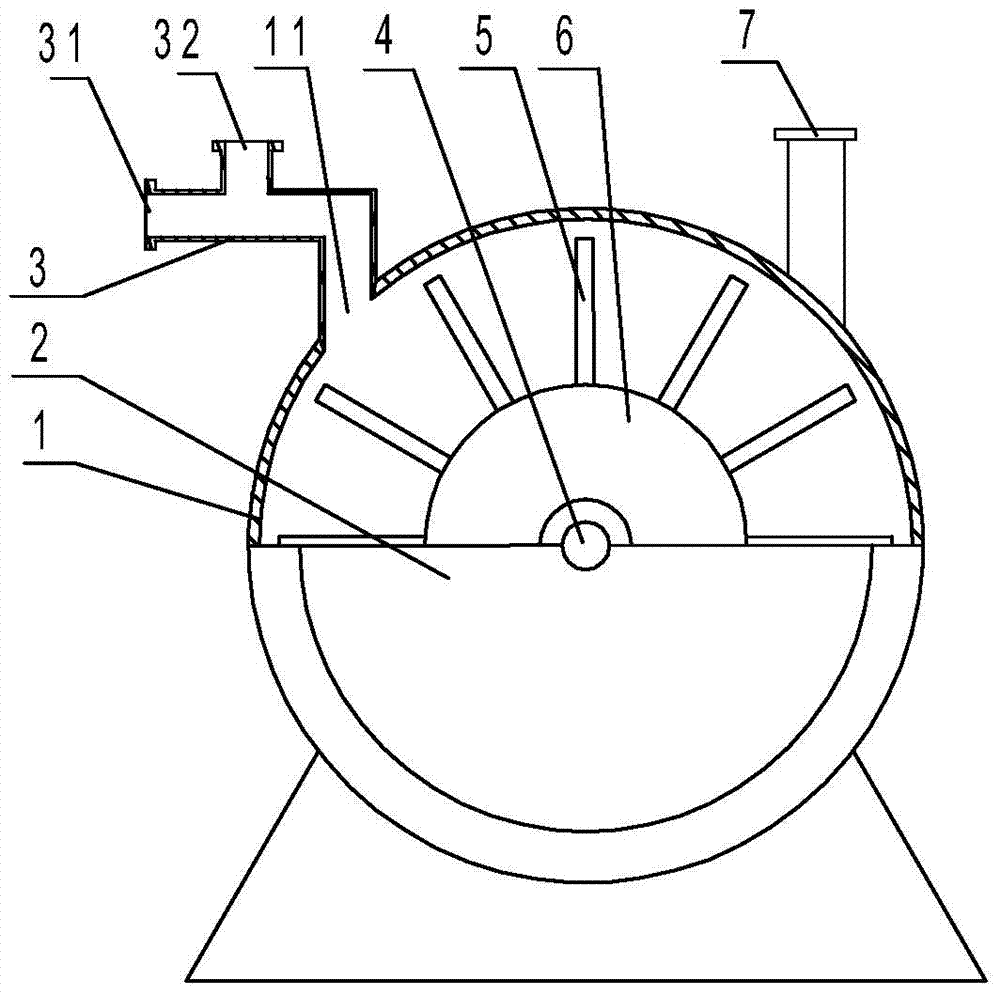

[0013] Soybean milk obtained by washing, soaking, refining, and filtering soybeans is heated to 80-95°C, and then processed through a hydraulic cavitation device capable of generating eddy currents. The hydraulic cavitation device used in this embodiment is mainly composed of a pump body 1. The pump cover 2, the rotating shaft 4 and the impeller 6 with blades 5 installed on the rotating shaft are composed. The upper part of the pump body is respectively provided with a suction inlet 11 and a soybean milk outlet 7. The suction inlet is connected with a soybean milk inlet 31 and a gas inlet. The suction pipe 3 of 32 communicates. Soymilk enters the pump body 1 from the soymilk inlet 31, and at the same time feeds food-grade carbon dioxide gas or food-grade nitrogen gas from the gas inlet 32 (the purpose of adding g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com