Printed circuit board and mixed surface treatment process thereof

A printed circuit board and surface treatment technology, which is applied in the secondary treatment of printed circuits, reinforcement of conductive patterns, and application of non-metallic protective layers. A large number of problems such as labor of red glue paper, to achieve the effect of reducing costs, high economic value, and reducing the residual rate of blue glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

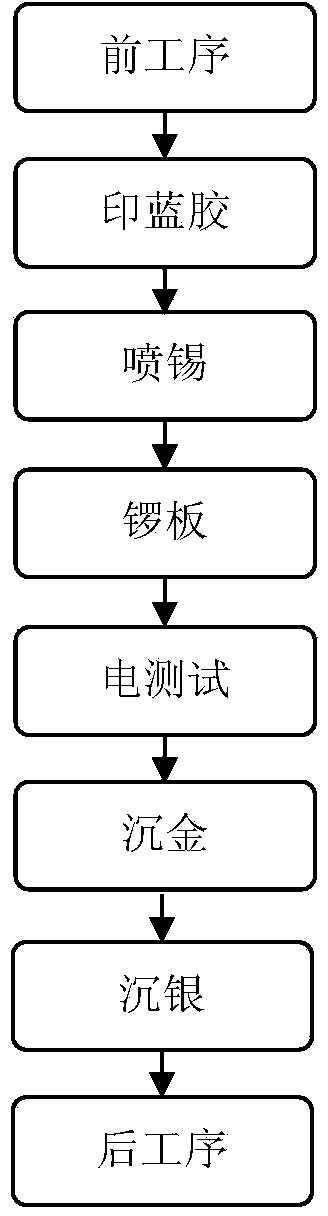

[0043] This embodiment is a mixed surface treatment process for printed circuit boards, including the following processes: pre-process, blue glue printing, tin spraying process, gong board, electrical test, immersion gold, immersion silver and post-process;

[0044] Described printing blue glue operation comprises following process parameter:

[0045] (1) By printing blue glue on the surface of the circuit board, selectively expose the holes that need to be sprayed with tin.

[0046] The main process is as follows: tin-spray hole blue plastic film window is designed so that each side of the light blocking point is 5mil larger than the aperture (1mil=0.0254mm);

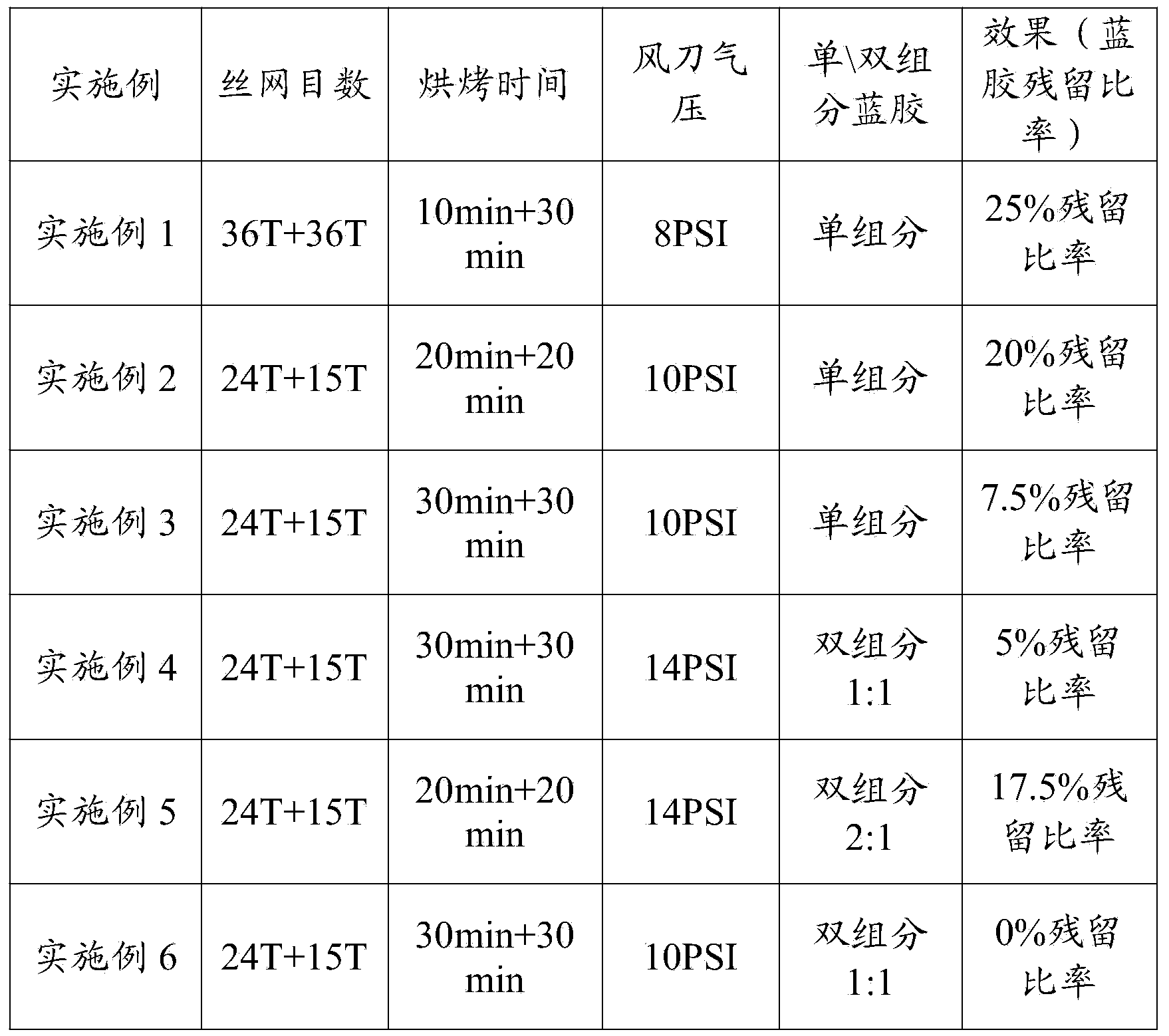

[0047] Use screen printing blue glue twice, use 36T screen for the first time, use 36T screen for the second time; print the component surface first, bake at 135±5°C for 10 minutes after printing, and then print the soldering surface, and then print at 150 Bake at ±5°C for 30 minutes;

[0048] The blue glue is blue g...

Embodiment 2

[0067] The other steps were the same as in Example 1, and the mesh size, baking time and tin-spraying air knife pressure were adjusted.

[0068] Use screen printing blue glue twice, use 24T screen for the first time, and use 15T screen for the second time; print the component surface first, bake at 130°C for 20min after printing, and then print the soldering surface, and then print at 150°C Bake for 20 minutes; use 10PSI air pressure for tin spraying air knife.

[0069] The blue glue is the blue glue B of SD-2955 model.

[0070] Result: 40 circuit boards were tested, and there were blue glue in 8 holes in all inspections, and the residual ratio of blue glue in the holes was 20%.

Embodiment 3

[0072] The other steps were the same as in Example 1, and the mesh size, baking time and tin-spraying air knife pressure were adjusted.

[0073] Use screen printing blue glue twice, use 24T screen for the first time, and use 15T screen for the second time; print the component surface first, bake at 130°C for 30 minutes after printing, then print the soldering surface, and then print at 150°C Bake for 30 minutes; use 10PSI air pressure for tin spraying air knife.

[0074] The blue glue is blue glue A of SD-2954 model.

[0075] Results: 40 circuit boards were tested, and there were blue glue in the holes of 3 of them, and the residual ratio of blue glue in the holes was 7.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com