Synthesis-auxiliary-free polyphenylene sulfide resin industrial synthetic process

A technology of polyphenylene sulfide resin and auxiliary agent is applied in the field of polymer material resin synthesis to achieve the effects of improving production efficiency, reducing cost and improving reaction speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

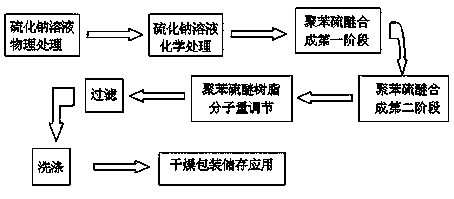

Image

Examples

Embodiment 1

[0032] at 28m 3 316L stainless steel autoclave, sodium sulfide (Na 2 S): Sodium hydroxide (NaOH): p-dichlorobenzene (abbreviation: p-DCB): The molar ratio of NMP is 0.98: 0.30:1.00:2.30; the industrial synthesis process includes:

[0033] 1) In the dehydration treatment stage of sodium sulfide and sodium hydroxide, under the protection of nitrogen and the stirring speed of the stirring blade is 33rmp, sodium sulfide is dissolved in anaerobic water to form a transparent solution containing sodium sulfide with a concentration of 18%wt. Sodium hydroxide is dissolved in anaerobic water to form a transparent solution containing sodium hydroxide concentration of 38%wt. Sodium sulfide and sodium hydroxide are added in a 316L stainless steel reactor with a molar ratio of 0.98:0.20, and heated to 130°C to make Sodium sulfide and sodium hydroxide are fully mixed and dissolved to form an aqueous solution of sodium sulfide and sodium hydroxide, and then the mixed solution containing sodi...

Embodiment 2

[0040] at 28m 3 316L stainless steel autoclave, sodium sulfide (Na 2 S): Sodium hydroxide (NaOH): p-dichlorobenzene (abbreviation: p-DCB): N-methylpyrrolidone (NMP) with a molar ratio of 1.18: 0.30: 1.28: 3.80; the industrial synthesis process includes:

[0041] 1) In the dehydration treatment stage of sodium sulfide and sodium hydroxide, under the protection of nitrogen and the stirring speed of the stirring blade is within 66rmp, sodium sulfide is dissolved in anaerobic water to form a transparent solution containing sodium sulfide with a concentration of 38%wt. Sodium hydroxide is dissolved in anaerobic water to form a transparent solution containing sodium hydroxide concentration of 88%wt. Sodium sulfide and sodium hydroxide are added in a 316L stainless steel reaction kettle with a molar ratio of 1.18:0.20, and heated to 130°C to make Sodium sulfide and sodium hydroxide are fully mixed and dissolved to form an aqueous solution of sodium sulfide and sodium hydroxide, and ...

Embodiment 3

[0049] at 28m 3 316L stainless steel autoclave, sodium sulfide (Na 2 S): sodium hydroxide (NaOH): p-dichlorobenzene (abbreviation: p-DCB): NMP molar ratio is 1.01:0.14:1.06:2.68; industrial synthesis process includes:

[0050] 1) In the dehydration treatment stage of sodium sulfide and sodium hydroxide, under the protection of nitrogen and the stirring speed of the stirring blade is 33-66rmp, sodium sulfide is dissolved in anaerobic water to form a sodium sulfide concentration of 18-38%wt The transparent solution of sodium hydroxide is dissolved in anaerobic water to form a transparent solution containing sodium hydroxide concentration of 38~88%wt. Sodium sulfide and sodium hydroxide are added in the 316L stainless steel reaction kettle with the molar ratio of 1.01:0.10, and Heating to 121°C to fully mix and dissolve sodium sulfide and sodium hydroxide to form an aqueous solution of sodium sulfide and sodium hydroxide, and then input the mixed solution containing sodium sulfi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com