Preparation method of polyvinyl acetal resin

A technology of polyvinyl acetal resin and polyvinyl alcohol, which is applied in the field of preparation of organic polymer compounds, can solve the problems of insufficient contact, poor acetalization uniformity, difficult washing, etc., achieves good uniformity and reduces the number of washings and water consumption, the effect of avoiding the difficulty of washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

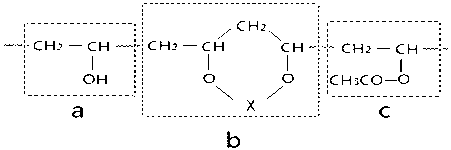

Image

Examples

Embodiment 1、2

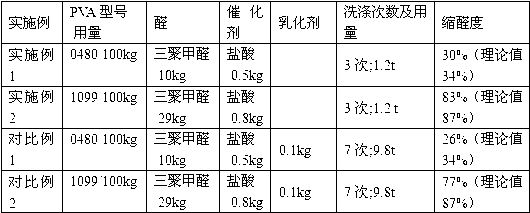

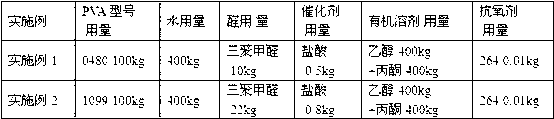

[0031] The synthetic process of embodiment 1,2 is identical with aftertreatment process.

[0032] (1) Synthetic process: the batch list of embodiment 1 and 2 is:

[0033]

[0034] Add polyvinyl alcohol and water to reactor A, stir and heat to the dissolution temperature of 80°C to form a polyvinyl alcohol solution, cool down to 10°C, add the formula amount of aldehyde and catalyst to reactor A at the same time, and then add anti Oxygen agent, carry out acetalization reaction, keep the temperature in the range of 10-13°C during the reaction process, when the product is precipitated as powder or floc, continue the reaction for 1 hour, and then add the formula amount of ethanol into the reactor A, Keep the temperature at 30°C, continue the reaction for 10 hours, and keep the material in the reactor A at 30°C for standby, that is, a mixed material containing the product—polyvinyl acetal resin is obtained in the reactor A.

[0035] (2) Post-processing process:

[0036] Add 140...

Embodiment 3~7

[0047] The synthesis and post-treatment basic technological process of embodiment 3~7 is the same.

[0048] (1) Synthetic process: the list of ingredients in Examples 3 to 7 (the dosage unit is kg) is:

[0049] Add polyvinyl alcohol and water to reactor A, stir and heat to the dissolution temperature of 90°C to form a polyvinyl alcohol solution, cool down to 25°C, add the formula amount of aldehyde and catalyst to reactor A at the same time, and then add anti Oxygen agent, carry out acetalization reaction, keep the temperature in the range of 25-27°C during the reaction process, when the product is precipitated as powder or floc, continue the reaction for 2 hours, and then add the organic solvent of the formula amount into the reactor A , keep the temperature at 65°C, continue the reaction for 5 hours, and keep the material in the reactor A at 60°C for standby, that is, a mixed material containing the product—polyvinyl acetal resin is obtained in the reactor A.

[0050] (2)...

Embodiment 5

[0059] Embodiment 5 and the main formula parameter of comparative example 3,4 and product result contrast:

[0060]

[0061] It can be seen from the comparison of the above table that the method of the present invention has higher utilization rate of raw material butyraldehyde, fewer post-treatment times and water consumption, and better uniformity of acetalization degree of the product. Comparing Comparative Example 3 and Example 5, the degree of acetalization of the two is basically the same, but the haze of the latter is significantly smaller than that of the former, indicating that the degree of acetalization of the latter is more uniform, while the distribution of degree of acetalization of the former is wider.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com