A method for preparing size-controllable nitrogen-doped carbon quantum dots

A technology of carbon quantum dots and nitrogen doping, applied in the field of nanomaterials, can solve the problems of using carbon and nitrogen sources alone and harsh preparation conditions, and achieve the effect of cheap raw materials, low preparation temperature and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0023] Add 2.9 mL of triisopropanolamine into 60 mL of ethanol and stir. After stirring evenly, slowly add 0.5 mL of dilute sulfuric acid (6.5%) and stir to obtain a uniform solution. The obtained solution was slowly transferred into a 90 mL polytetrafluoroethylene-lined stainless steel autoclave, placed in a constant temperature drying oven, and reacted at 120 °C for 12 h to obtain a light yellow stock solution of carbon quantum dots. The formed carbon quantum dot stock solution was injected into a dialysis bag for dialysis. The molecular weight of the dialysis bag was 500 Da, and the dialysis time was 72 h. The water was changed every 12 h to obtain a nitrogen-doped carbon quantum dot dispersion. The obtained nitrogen-doped carbon quantum dot dispersion was dried at 60°C to obtain a concentrate, and the concentrate was freeze-dried at -80°C to obtain a nitrogen-doped carbon quantum dot solid.

Embodiment approach 2

[0025] Add 4.9 mL of triisopropanolamine into 60 mL of ethanol and stir. After stirring evenly, slowly add 1.5 mL of dilute nitric acid (5.0 %), and stir to obtain a uniform solution. The obtained solution was slowly transferred into a 90 mL polytetrafluoroethylene-lined stainless steel autoclave, placed in a constant temperature drying oven, and reacted at 120 °C for 12 h to obtain a yellow carbon quantum dot stock solution. The formed carbon quantum dot stock solution was injected into a dialysis bag for dialysis. The molecular weight of the dialysis bag was 500 Da, and the dialysis time was 72 h. The water was changed every 12 h to obtain a nitrogen-doped carbon quantum dot dispersion. The obtained nitrogen-doped carbon quantum dot dispersion liquid was dried at 60°C to obtain a concentrated liquid, and the concentrated liquid was freeze-dried at -80°C to obtain a nitrogen-doped carbon quantum dot solid.

Embodiment approach 3

[0027] Add 10.0 mL of triisopropanolamine into 60 mL of ethanol and stir, after stirring evenly, slowly add 2.0 mL of H 2 o 2 (30%), stirred to obtain a homogeneous solution. The obtained solution was slowly transferred into a 90 mL polytetrafluoroethylene-lined stainless steel autoclave, placed in a constant temperature drying oven, and reacted at 120 °C for 12 h to obtain a brownish-yellow carbon quantum dot stock solution. The formed carbon quantum dot stock solution was injected into a dialysis bag for dialysis. The molecular weight of the dialysis bag was 500 Da, and the dialysis time was 72 h. The water was changed every 12 h to obtain a nitrogen-doped carbon quantum dot dispersion. The obtained nitrogen-doped carbon quantum dot dispersion liquid was dried at 60°C to obtain a concentrated liquid, and the concentrated liquid was freeze-dried at -80°C to obtain a nitrogen-doped carbon quantum dot solid.

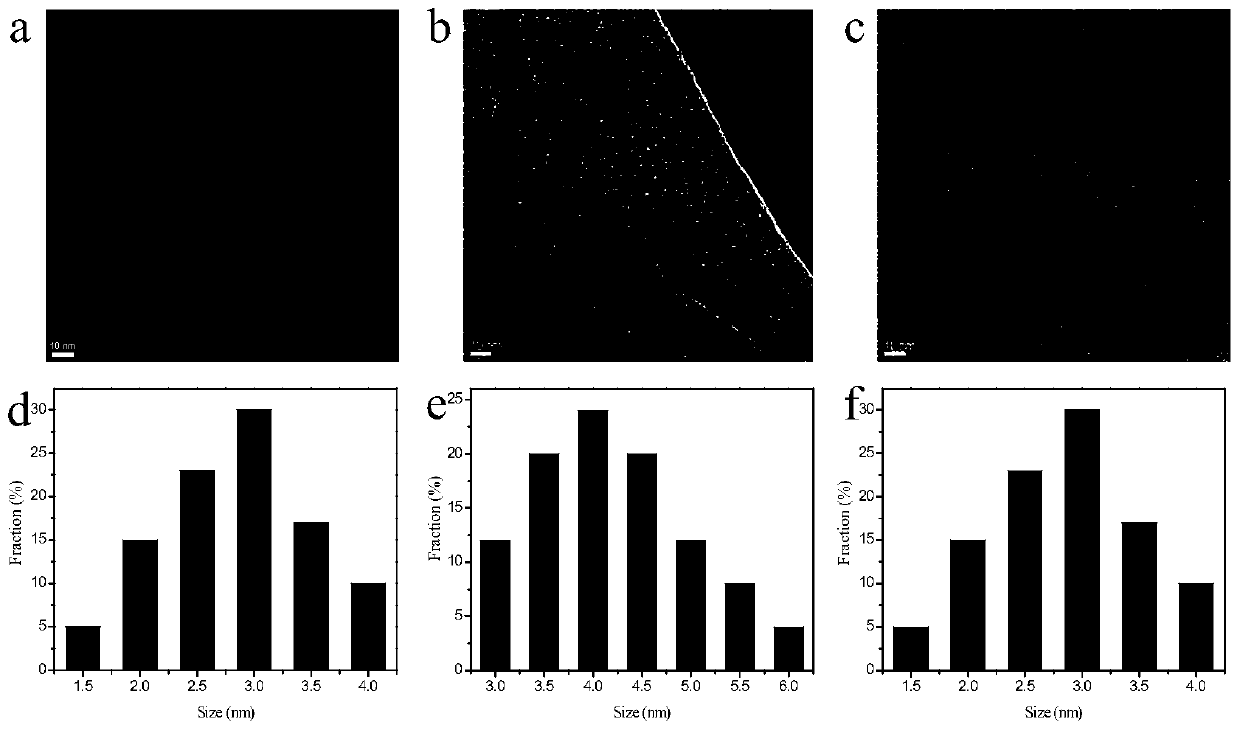

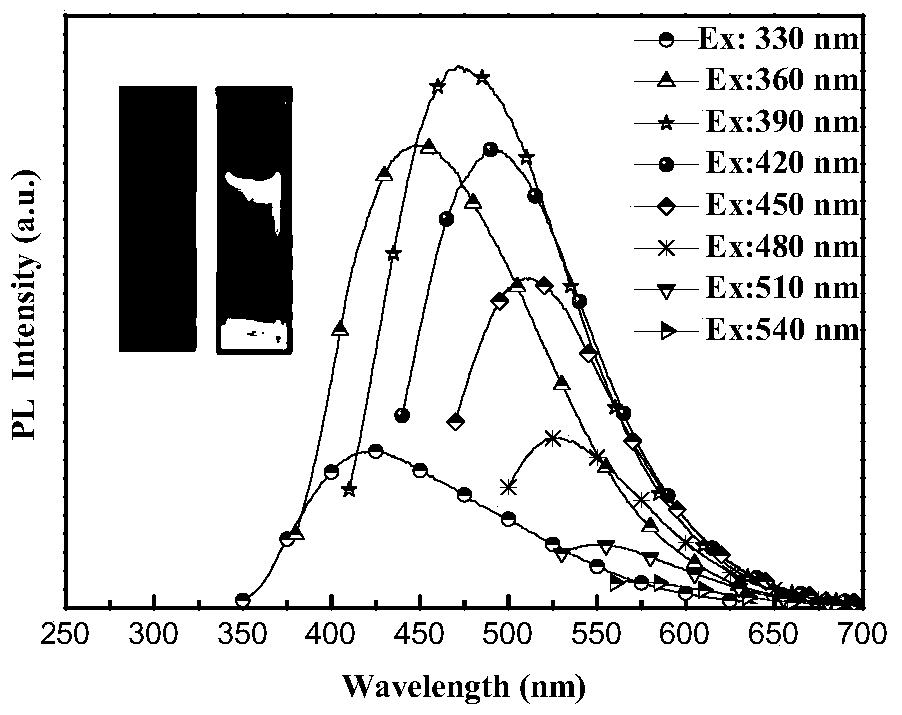

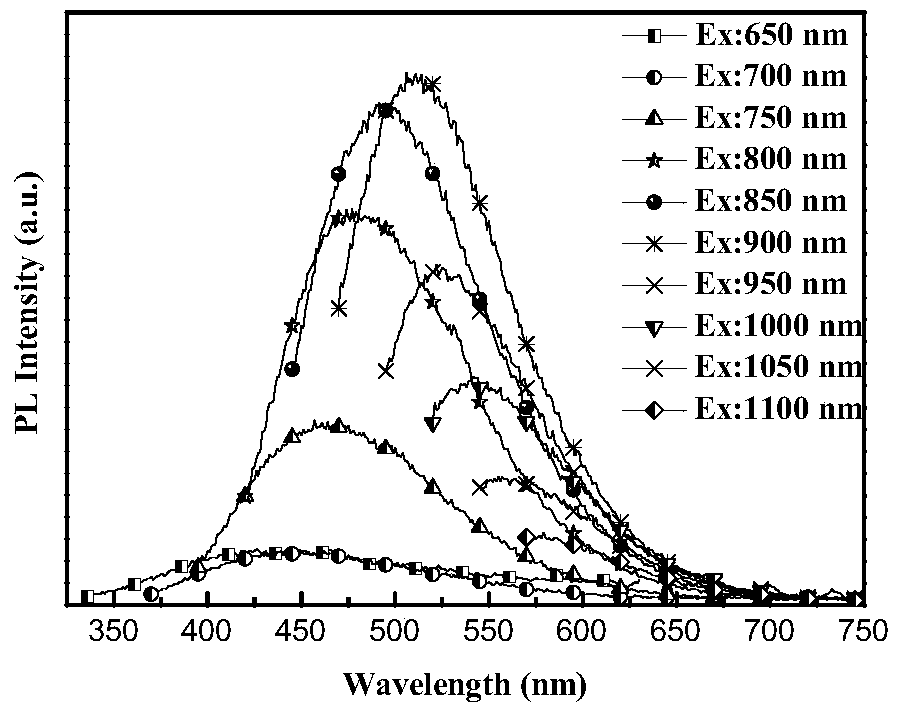

[0028] The example samples were characterized.

[0029] The morph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com