Liquid crystal display and method for manufacturing same

A technology of liquid crystal display and manufacturing method, which is applied to instruments, nonlinear optics, optics, etc., can solve the problems of complex production process, increased display energy consumption, and is not suitable for industrial applications, and achieves the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

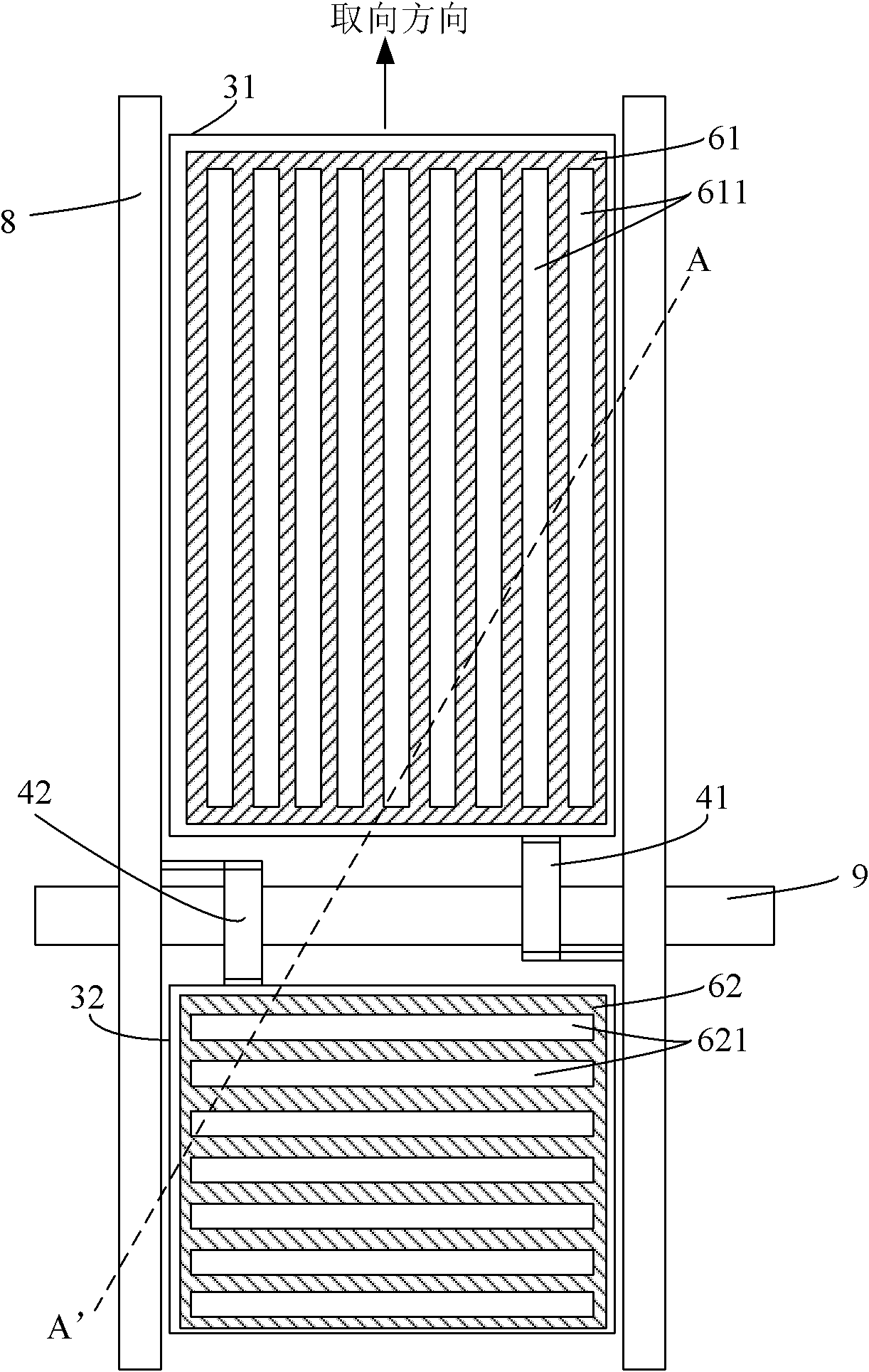

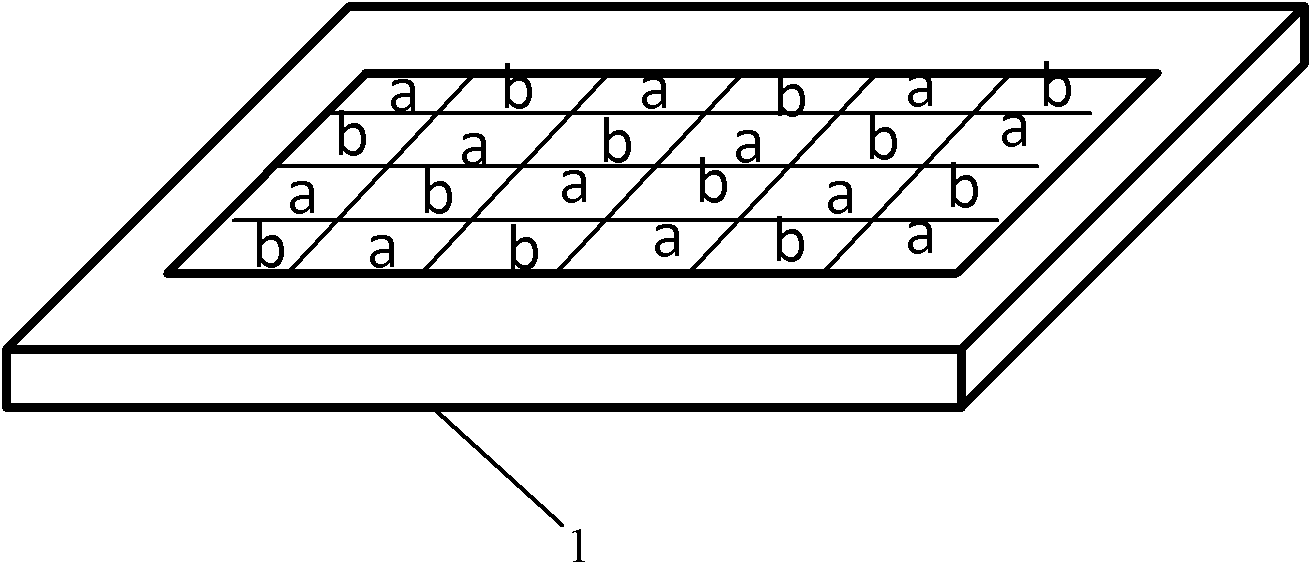

[0044] The invention provides a liquid crystal display and a manufacturing method thereof, which realizes the control of the viewing angle of the liquid crystal display through a special pixel structure, thereby eliminating the need to add an additional viewing angle control device in the liquid crystal display, thus simplifying the production of the liquid crystal display with controllable viewing angle process, reducing production costs. The present invention will be further described through specific embodiments below in conjunction with the accompanying drawings.

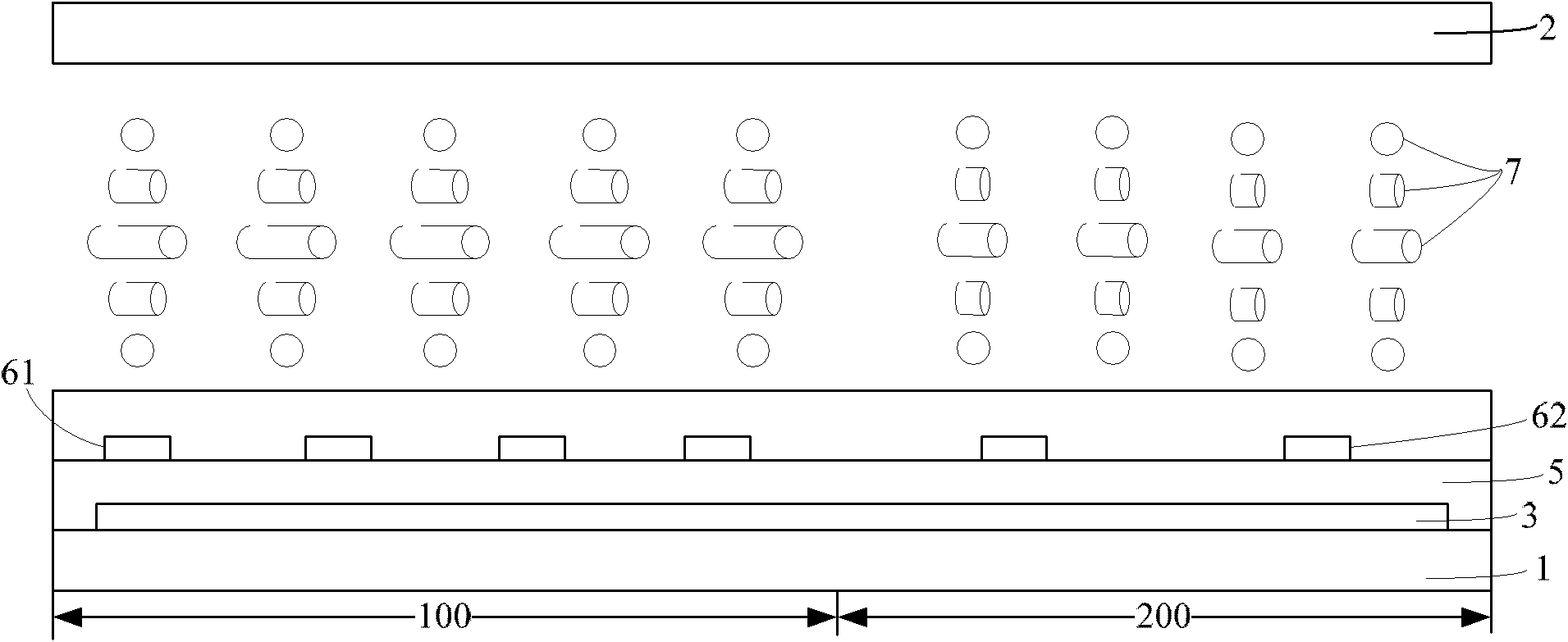

[0045] Please refer to Figure 1~2 ,in figure 1 is a top view of the pixel structure described in the embodiment of the present invention, figure 2 The pixel structure described in the embodiment of the present invention is along figure 1 The cross-sectional view of the A-A' direction in (the gate line is not shown).

[0046] Such as Figure 1~2 As shown, the pixel structure described in the embodiment of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com