A method of manufacturing a polymer solid aluminum electrolytic capacitor suitable for AC circuits

A technology for electrolytic capacitors and manufacturing methods, applied in solid electrolytic capacitors, electrolytic capacitors, capacitors, etc., can solve the problems of restricting the use of solid capacitors, low formation voltage, and inability to apply AC circuits, and achieves benefits such as absorption and impregnation, production costs Low, good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

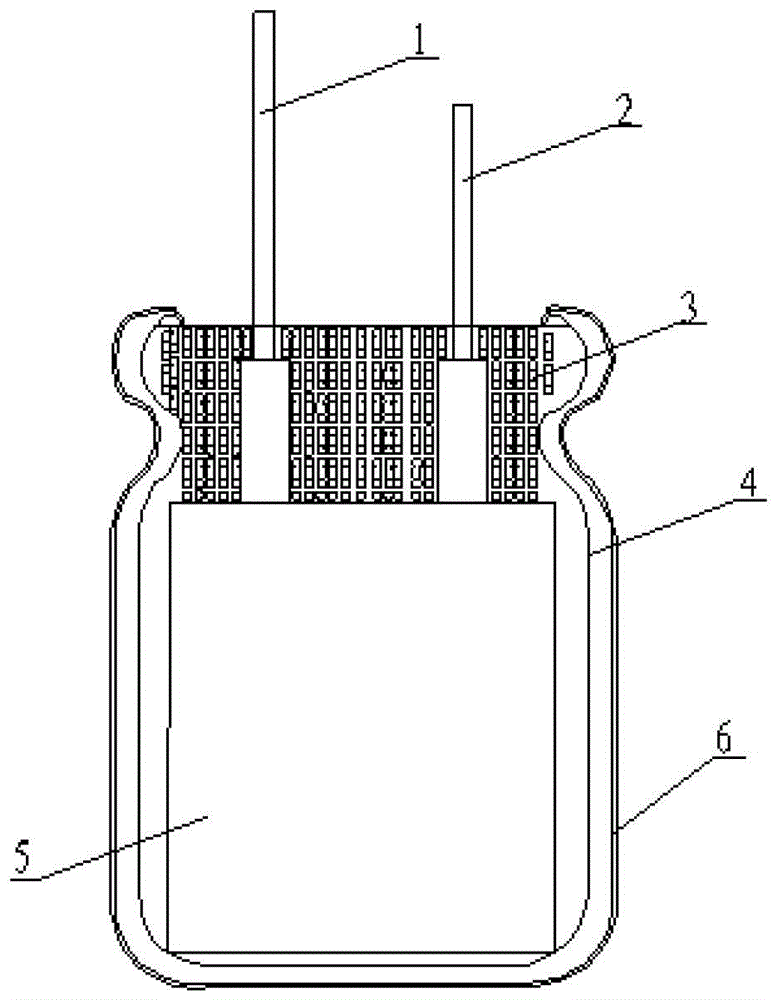

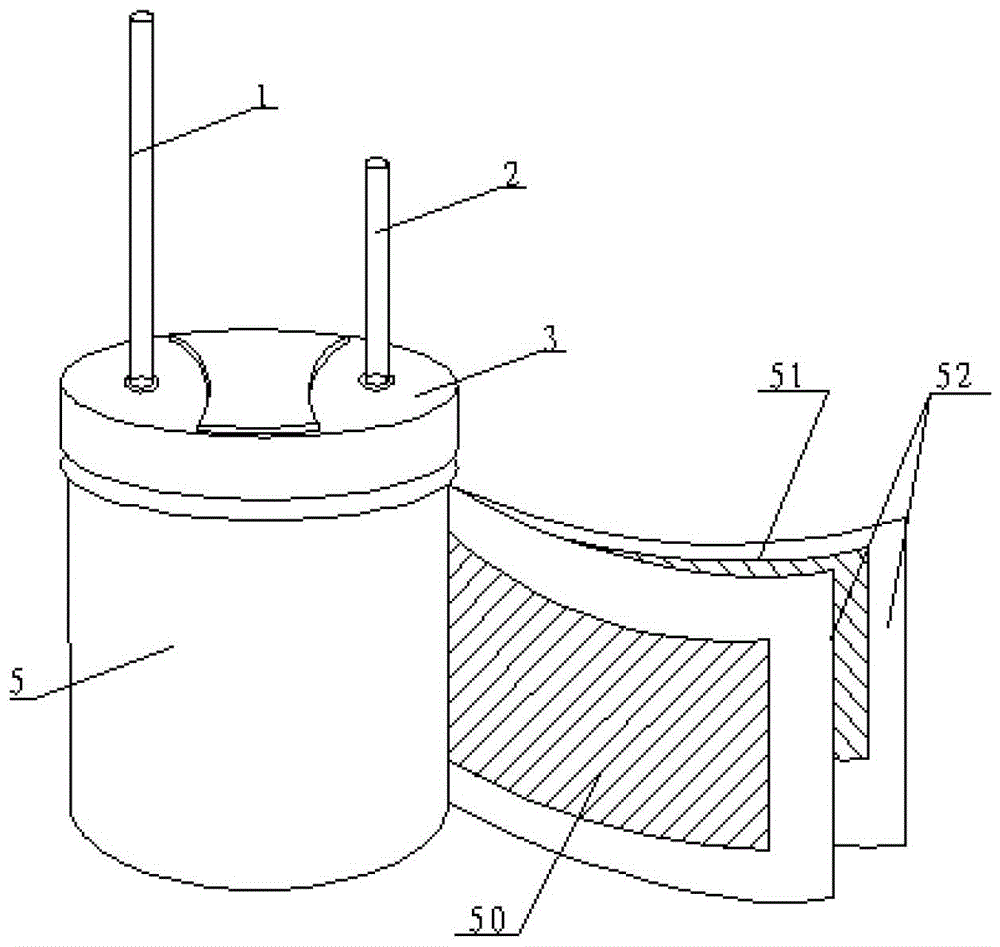

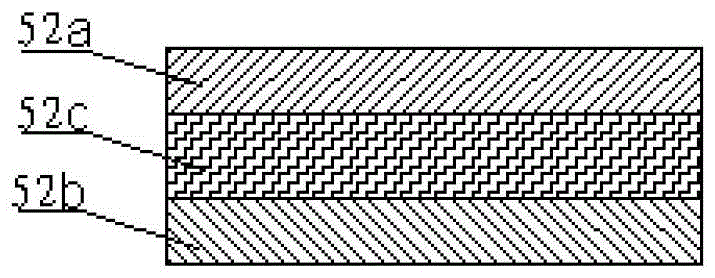

[0032] refer to Figure 1 to Figure 3 , this embodiment provides a polymer solid aluminum electrolytic capacitor suitable for AC circuits, which includes a first connection terminal 1 , a second connection terminal 2 , a rubber cover 3 , an aluminum shell 4 and a core package 5 . The core pack 5 is composed of a first anodized aluminum foil 50 , a second anodized aluminum foil 51 , electrolytic paper 52 and a polymer electrolyte. The upper end of the first anodized aluminum foil 50 is riveted to the first connection terminal 1 , and the upper end of the second anodized aluminum foil 51 is riveted to the second connection terminal 2 . The electrolytic paper 52 is further composed of three layers of non-woven fabrics, wherein the upper layer 52a and the lower layer 52b are respectively polyester spunbonded nonwovens with a thickness of about 20 μm; the middle layer 52c is a PET nonwoven with a thickness of 25 μm, forming a polyester spunbonded nonwoven The polyester fibers of t...

Embodiment 2

[0041] This embodiment provides a method for manufacturing a 4V220μF 8*8mm shell size capacitor product. The structure of the capacitor product is the same as that in Embodiment 1. The method specifically includes the following steps:

[0042] (1), using an anodized aluminum foil with a formation voltage of 7.7V, riveting the guide pin on the anodized aluminum foil;

[0043] (2), take two pieces of anodized aluminum foils riveted with guide pins, and use the electrolytic paper described in Example 1 in the middle, wind it into a core bag with a theoretical capacity of 330 μF, and fix it with adhesive tape;

[0044] (3) Weld the two guide pins of the core package on the iron bar, immerse them in the chemical solution, make the chemical solution just submerge the core package, apply a 7.7V forming voltage, and perform chemical conversion repair on the two anodized aluminum foils at the same time, The processing time is 40 minutes;

[0045] (4), putting the core bag after chemic...

Embodiment 3

[0057] This embodiment provides a method for manufacturing a 6.3V470μF 8*12mm shell size capacitor product. The structure of the capacitor product is the same as that in Embodiment 1. The method specifically includes the following steps:

[0058] (1) Anodized aluminum foil with a formation voltage of 11V is used, and the guide pin is riveted on the anodized aluminum foil;

[0059] (2), take two pieces of anodized aluminum foils riveted with guide pins, and separate them with the electrolytic paper described in Example 1 in the middle, wind them into a core bag with a theoretical capacity of 660 μF, and fix them with adhesive tape;

[0060] (3) Weld the two guide pins of the core package on the iron bar, immerse them in the chemical solution, make the chemical solution just submerge the core package, apply a forming voltage of 11V, and perform chemical conversion repair on the two anodized aluminum foils at the same time. The time is 40 minutes;

[0061] (4), putting the core ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com