High-impact strength PVC pinch plate and making method thereof

A high-impact, PVC resin technology, used in the field of interior decoration materials, can solve the problems of heavy PVC gusset plate, reduced flame retardant performance, limited impact performance, etc., and achieve good social and economic benefits, and flame retardant performance is green. Environmentally friendly, high impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

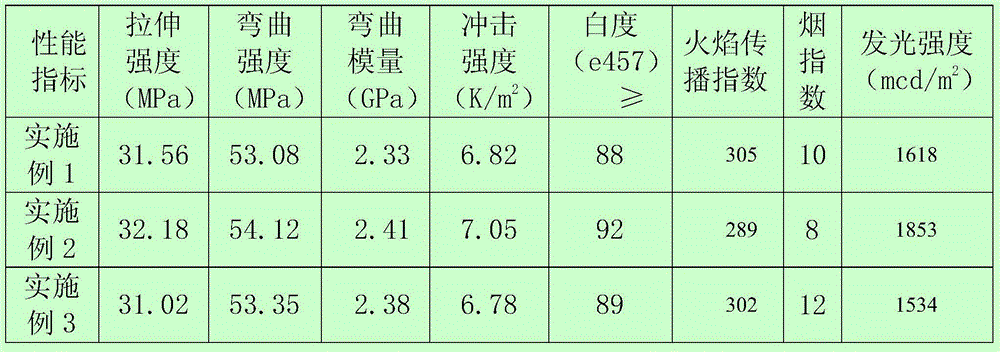

Embodiment 1

[0030] A PVC gusset plate with high impact strength, made of the following raw materials in parts by weight: 45kg of PVC resin, 110kg of heavy calcium carbonate, 3kg of liquid zinc-tin stabilizer, 1kg of PE wax, 1kg of stearic acid, and 3.5kg of titanium dioxide , brightener 0.1kg, recycled PVC waste 10kg, ACM impact modifier 2kg, light storage powder 0.05kg, nano silicon dioxide 1kg, foaming agent 0.3kg, micropore regulator 0.03kg, halogen-free flame retardant 3kg .

[0031] Wherein, the PVC resin is Type 7 or Type 5 PVC resin, which is mixed with recycled PVC waste as a base material; the ground calcium carbonate is ultrafine ground calcium carbonate with a particle size of 0.5-0.8 μm , which is used as an inorganic filler; the halogen-free flame retardant is polyphosphoramide; the PE wax is an external lubricant, and stearic acid is an internal lubricant, which is used to improve the processing performance of materials; Silicon oxide is a reinforcing agent; the micropore r...

Embodiment 2

[0042] A PVC gusset plate with high impact strength, made of the following raw materials in parts by weight: 50kg of PVC resin, 115kg of heavy calcium carbonate, 3.6kg of liquid zinc-tin stabilizer, 1.6kg of PE wax, 1.4kg of stearic acid, titanium White powder 3.8kg, whitening agent 0.13kg, recycled PVC waste 15kg, ACM impact modifier 2.5kg, light storage powder 0.08kg, nano silicon dioxide 1.5kg, foaming agent 0.5kg, microporous regulator 0.05kg, none Halogen flame retardant 3.5kg.

[0043] Wherein, the PVC resin is Type 7 or Type 5 PVC resin, which is mixed with recycled PVC waste as a base material; the ground calcium carbonate is ultrafine ground calcium carbonate with a particle size of 0.5-0.8 μm , which is used as an inorganic filler; the halogen-free flame retardant is polyphosphoramide; the PE wax is an external lubricant, and stearic acid is an internal lubricant, which is used to improve the processing performance of materials; Silicon oxide is a reinforcing agent; t...

Embodiment 3

[0054] A PVC gusset plate with high impact strength, made of the following raw materials in parts by weight: 50kg of PVC resin, 120kg of heavy calcium carbonate, 4kg of liquid zinc-tin stabilizer, 2kg of PE wax, 2kg of stearic acid, 4kg of titanium dioxide, Whitening agent 0.15kg, recycled PVC waste 20kg, ACM impact modifier 3kg, light storage powder 0.1kg, nano silicon dioxide 2kg, foaming agent 0.8kg, micropore regulator 0.08kg, halogen-free flame retardant 4kg.

[0055] Wherein, the PVC resin is Type 7 or Type 5 PVC resin, which is mixed with recycled PVC waste as a base material; the ground calcium carbonate is ultrafine ground calcium carbonate with a particle size of 0.5-0.8 μm , which is used as an inorganic filler; the halogen-free flame retardant is polyphosphoramide; the PE wax is an external lubricant, and stearic acid is an internal lubricant, which is used to improve the processing performance of materials; Silicon oxide is a reinforcing agent; the micropore regul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com