Full-automatic machining process of air conditioner compressor scroll plate

An air-conditioning compressor, fully automated technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems that restrict the popularization of scroll compressors, unstable product quality variation, high production costs, etc., and achieve optimization The layout of equipment production lines, the effect of improving product quality and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

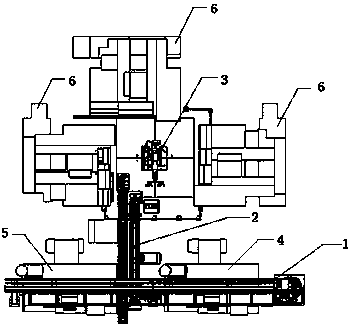

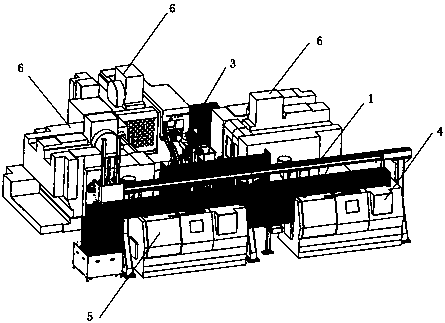

[0022] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

[0023] Such as figure 1 with figure 2 Shown, a kind of air-conditioning compressor scroll fully automatic processing technology, comprises the following steps:

[0024] S1. The workpiece is transported from the silo to the OP1 machining center 4 and OP2 machining center 5 by the manipulator I1, and the OP1 machining center 4 and OP2 machining center 5 process the workpieces one by one according to the loading order of the workpieces;

[0025] S2. The processed workpiece is transported by the manipulator II2 to the working area of the manipulator III3, and the manipulator III3 distributes the workpiece to the OP3 machining center 6;

[0026] S3, OP3 machining center 6 mills the vortex groove on the workpiece;

[0027] S4. The processed workpiece is transferred to the storage box by the manipulator III3.

[0028] In this embodiment, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com