Fibrilia down filler and manufacturing method thereof

A technology of hemp fiber and stuffing, which is applied in the field of hemp fiber down stuffing and its manufacture, can solve the problem of not being able to well improve down's easy-to-breed bacteria, mildew, smelly, unnatural and environmentally friendly, and the loss of bamboo's antibacterial and anti-mildew properties and other issues, to achieve the effect of eliminating processing procedures, saving chemical substances, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

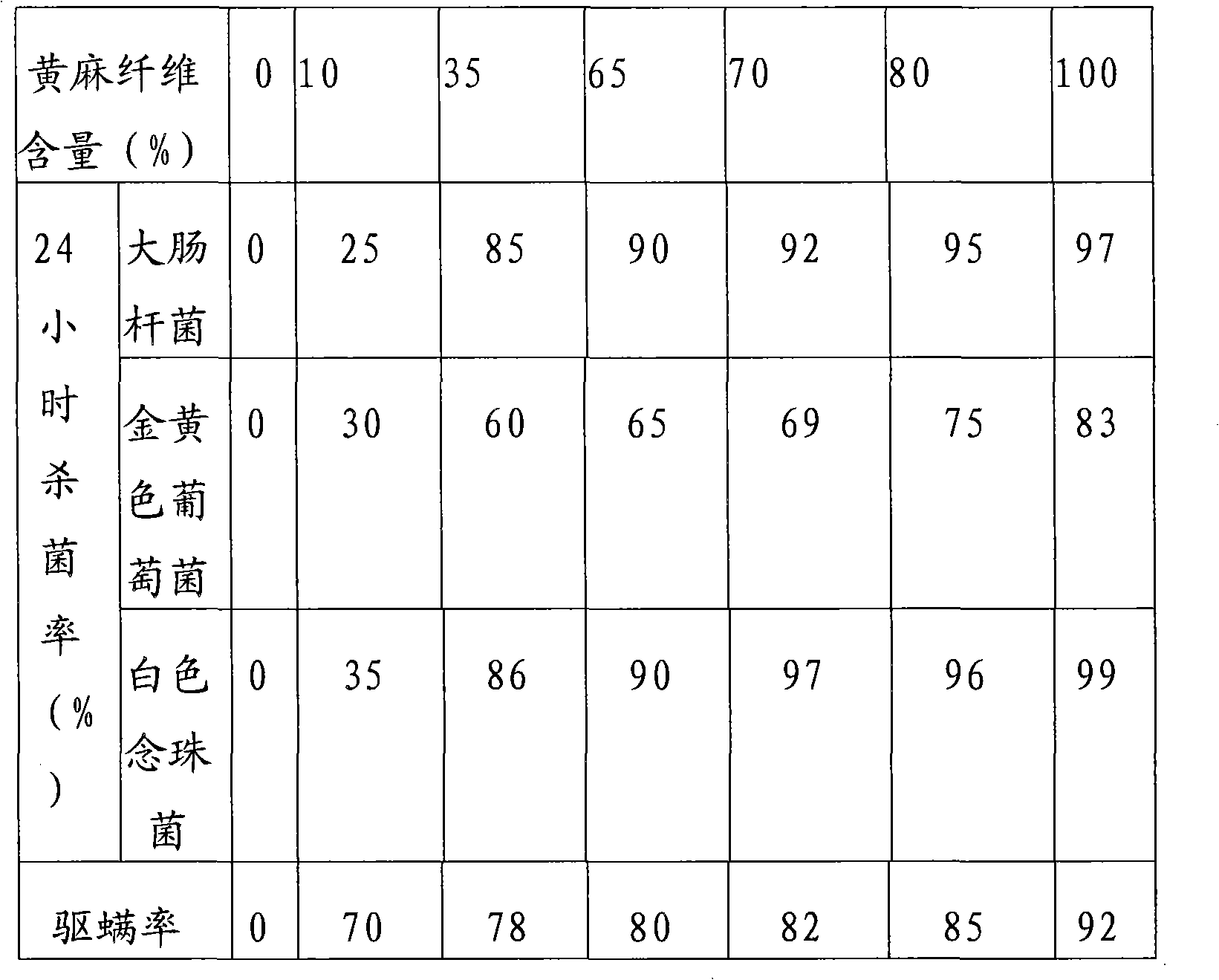

[0021] The hemp fiber down filler of the present invention is composed of hemp fiber and down fiber, wherein the mass percentage of the hemp fiber is 10-80%, and the mass percentage of the down fiber is 20-90%. As a preference, the mass percentage of the hemp fiber is 35-65%, and the mass percentage of the down fiber is 35-65%, which not only ensures a better heat preservation effect, but also ensures that the obtained hemp fiber The fiber down filling has better air permeability, anti-mildew and antibacterial effects. The down fiber is down or a mixture of down and feathers. By using a certain amount of hemp fiber instead of down fiber, the production cost of the enterprise is greatly reduced; at the same time, by adding natural hemp fiber with anti-mildew and anti-bacterial effect, the filling has anti-mildew and anti-bacterial effect, and the above-mentioned anti-mildew The antibacterial effect is obtained without adding any chemical substances, without any chemical anti-m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com