Manufacturing method of environment-friendly ecological waterproof roof

A production method and ecological technology, applied in the direction of roofing, roof covering, roof decoration, etc., can solve the problems of difficult maintenance, many construction layers, and difficult degradation of plastic products of plastic drainage boards, and achieve low cost, environmental protection, and enhanced thermal insulation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

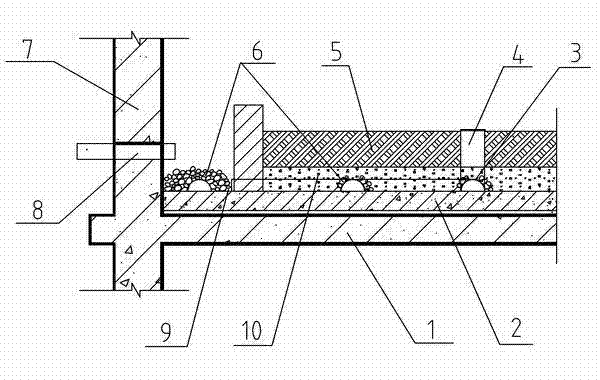

[0013] A method for making a green ecological waterproof roof, comprising the following steps:

[0014] 1. Repair the base of the cast-in-place roof, and slot and seal the joints between the roof-protruding structures (including parapets, tube wells and equipment bases, etc.) and the roof, and the cracks in the roof structural panels;

[0015] 2. Establish a rigid waterproof layer. On the roof 1 after the base repair, lay steel bars and pour concrete to form a 70mm thick rigid waterproof layer 2;

[0016] 3. Establish a drainage and steam exhaust layer, and lay a 120-150mm water filter layer 10 on the rigid waterproof layer 2. The water filter layer 10 is mainly composed of slag and pebbles. Groove, vertically and horizontally connected semicircular blind pipe 3 is placed in the drainage ditch, and there is one row or more than one row of water filtering holes on the bottom of the semicircular dead pipe 3, and the two sides of the semicircular blind pipe 3 are covered with peb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com