Environment-friendly toxic-free 3D printing consumable and preparation method thereof

A technology of 3D printing and consumables, applied in the direction of additive processing, etc., can solve the problems that the mechanical properties of synthetic materials are not significantly improved, the mechanical properties of consumables are not significantly improved, and cannot be promoted and applied on a large scale, so as to improve the finish and reduce production costs. , the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

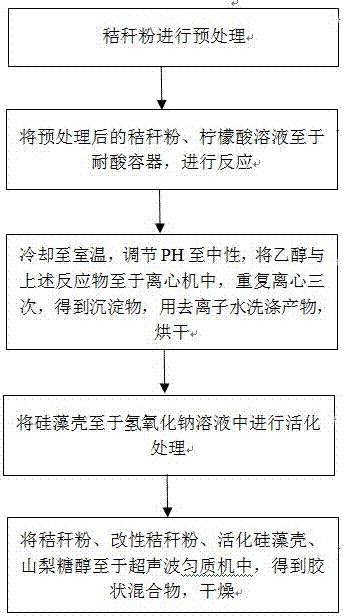

Method used

Image

Examples

Embodiment 1

[0026] (1) Weigh 5g of 100-mesh wheat straw, put it into a ball mill and mill it for 60 minutes;

[0027] (2) Put the milled wheat straw in a beaker, add 25g of acetic acid, seal it, soak at room temperature for 5 hours, and filter out excess acetic acid;

[0028] (3) Put the soaked wheat straw and 100ml of citric acid solution with a concentration of 15wt% in a three-necked flask equipped with a condenser, and react in a collector-type magnetic stirrer at 80°C and 600r / min for 12h;

[0029] (4) Cool the product obtained in step (3) to room temperature, adjust the pH to neutral, put it and 30ml of ethanol with a concentration of 95% in a centrifuge at a speed of 3000r / min for 30min, repeat the centrifugation three times, and obtain The precipitate was washed with deionized water, dried and pulverized at last;

[0030] (5) Weigh 0.1g of diatom frustules into a beaker, add 5ml of NaOH solution with a concentration of 6wt%, seal it, and soak it at room temperature for 5h;

[00...

Embodiment 2

[0034] (1) Weigh 5g of 150-mesh straw, put it into a ball mill and mill it for 60 minutes;

[0035] (2) Put the ball-milled straw into a beaker, add 30g of acetic acid, seal it, soak it at room temperature for 4 hours, and filter out excess acetic acid;

[0036] (3) Put the soaked rice straw and 100ml of 20wt% citric acid solution in a three-neck flask equipped with a condenser, and react in a 650r / min collector magnetic stirrer at 90°C for 15h;

[0037] (4) Cool the product obtained in step (3) to room temperature, adjust the pH to neutral, place it and 40ml of ethanol with a concentration of 95% in a centrifuge at a speed of 3500r / min for 25min, repeat the centrifugation three times, and obtain The precipitate was washed with deionized water, dried and pulverized at last;

[0038] (5) Weigh 0.12g of diatom frustules into a beaker, add 6ml of NaOH solution with a concentration of 6wt%, seal it, and soak it at room temperature for 5h;

[0039] (6) Put the product obtained in...

Embodiment 3

[0042] (1) Weigh 5g of 200-mesh corn stalks, put them into a ball mill and mill for 55 minutes;

[0043] (2) Put the ball-milled corn stalks in a beaker, add 30g of acetic acid, seal it, soak it at room temperature for 4 hours, and filter out excess acetic acid;

[0044] (3) Put the soaked corn stalks and 100ml of 20wt% citric acid solution in a three-necked flask equipped with a condenser, and react in a collector-type magnetic stirrer at 90°C and 750r / min for 15h;

[0045] (4) Cool the product obtained in step (3) to room temperature, adjust the pH to neutral, put it and 40ml of ethanol with a concentration of 95% in a centrifuge at a speed of 4500r / min for 25min, repeat the centrifugation three times, and obtain The precipitate was washed with deionized water, dried and pulverized at last;

[0046] (5) Weigh 0.13g of diatom frustules into a beaker, add 8ml of NaOH solution with a concentration of 6wt%, seal it, and soak it at room temperature for 6h;

[0047](6) Put the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com