Patents

Literature

35results about How to "Comply with packaging requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High chemical resistance borosilicate glass and purpose thereof

InactiveCN101717189AComply with packaging requirementsReduce manufacturing costPharmaceutical containersMedical packagingWorking temperaturePack material

The invention discloses high chemical resistance borosilicate glass, comprising the following components based on oxides in percentage by weight: 71-75 SiO2, 3-6 Al2O3, 8-10 B2O3, 4-10 Na2O and 0-2.5 K2O, 0-1.2 CaO, 0-1 MgO, 1-3 BaO and 0-0.3 CeO2, wherein Na2O+K2O ranges from 7 to 10, and CaO+MgO ranges from 0 to 1.2. The invention has the following advantages: 1. As2O3, Sb2O3, BaSO4 and other harmful substances are not used in constituents, and the borosilicate glass can be used as a material for packing medicines; and 2. tested by experiments, the high chemical resistance borosilicate glass prepared from the constituents by the traditional production equipment has the coefficient of heat expansion ranging from 5.0*10<-6> K<-1> to 6.0*10<-6> K<-1>, the inversion temperature Tg ranging from 520 DEGC to 572 DEGC, the softening point ranging from 765 DEGC to 782 DEGC, the working temperature ranging from 920 DEGC to 1200 DEGC and the density ranging from, 2.32 g / cm<3> to 2.5g / cm<3>, which meet the requirement on medicinal packing and reduces the production cost.

Owner:SHANDONG LINUO NEW MATERIAL

Modified polyurethane resin and benzene-free and ketone-free composite plastic ink containing same, as well as preparation methods thereof

The invention relates to benzene-free and ketone-free composite plastic ink which comprises 25-35 parts of modified polyurethane resin, 5-10 parts of matching resin (polyketone resin), 0.5-1 part of dispersant, 7-15 parts of pigment, 2-4 parts of adhesion promoter, 0.1-0.3 part of wax powder, 10-15 parts of ethanol, 20-30 parts of acetic ether and 10-20 parts of isopropyl alcohol, wherein the matching resin is L-872 polyketone resin, the contents of the ethanol, the isopropyl alcohol and the acetic ether are all above 99%, the content of benzene and ketone substances is below 0.01%, the dispersant is TM-950, the adhesion promoter is a titanate coupling agent HY-201, and the wax powder is polyethylene wax. The benzene-free and ketone-free composite plastic ink takes the isopropyl alcohol, the acetic ether and the ethanol as diluents without the assistance of the benzene and ketone substances for dissolving. The benzene-free and ketone-free composite plastic ink has no harm to operators, society and environment from preparation and production to printing and use and has excellent safe and healthy property.

Owner:新东方油墨有限公司

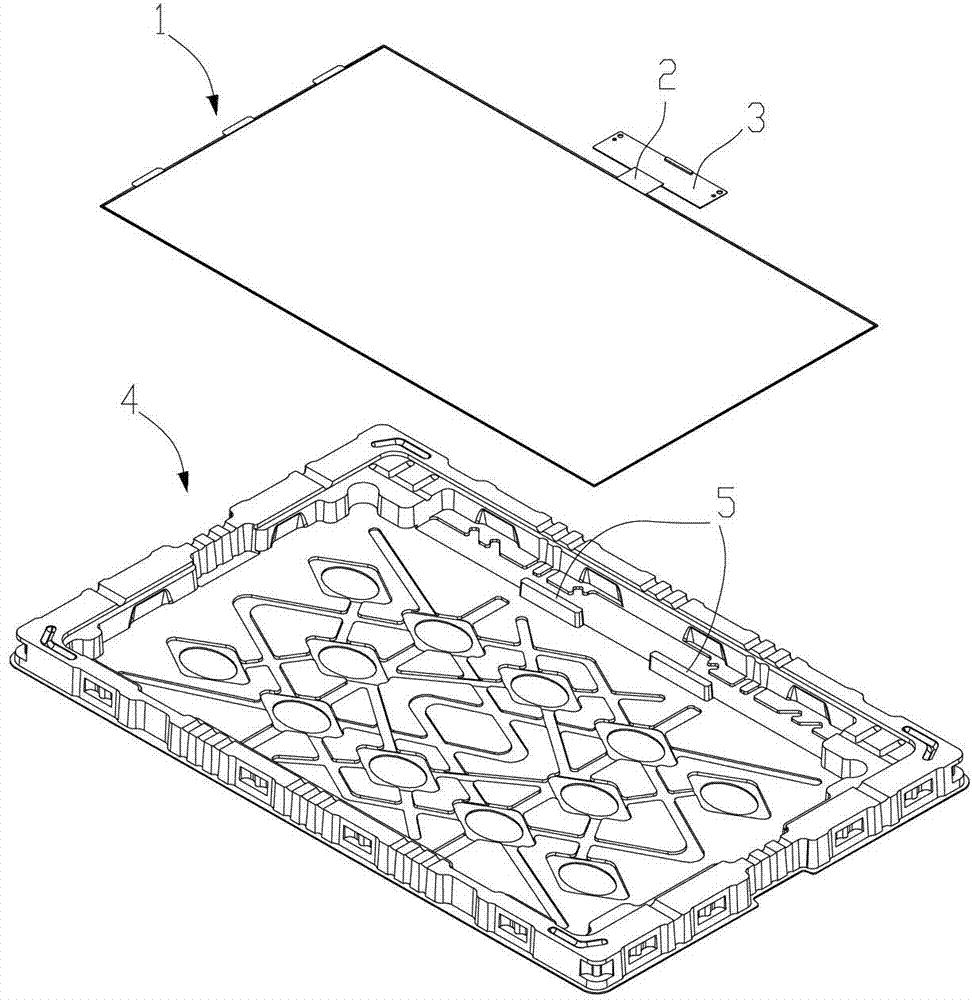

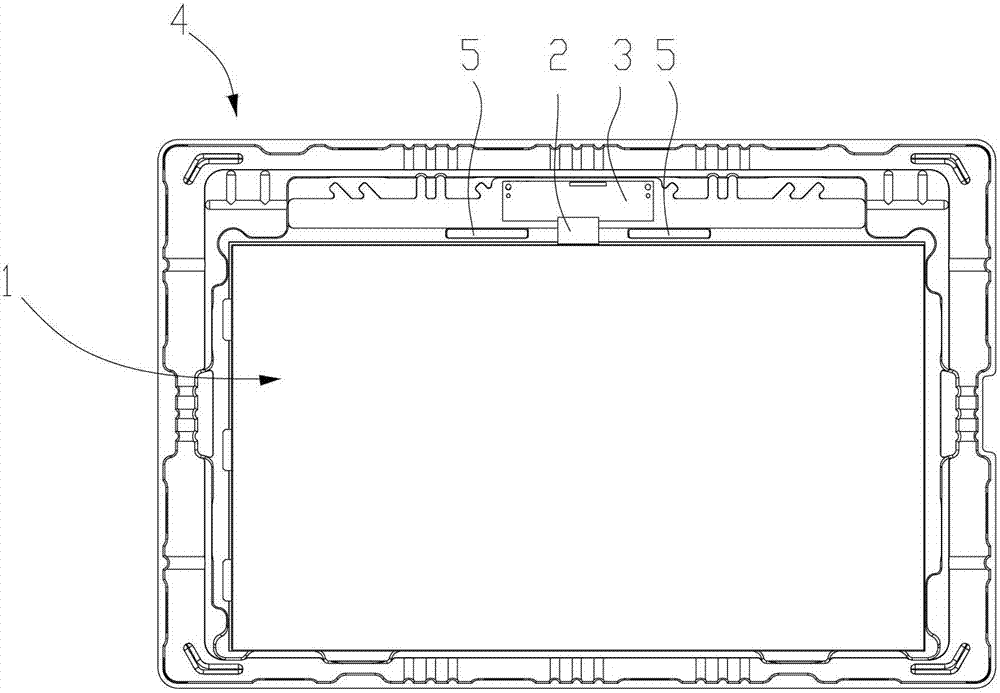

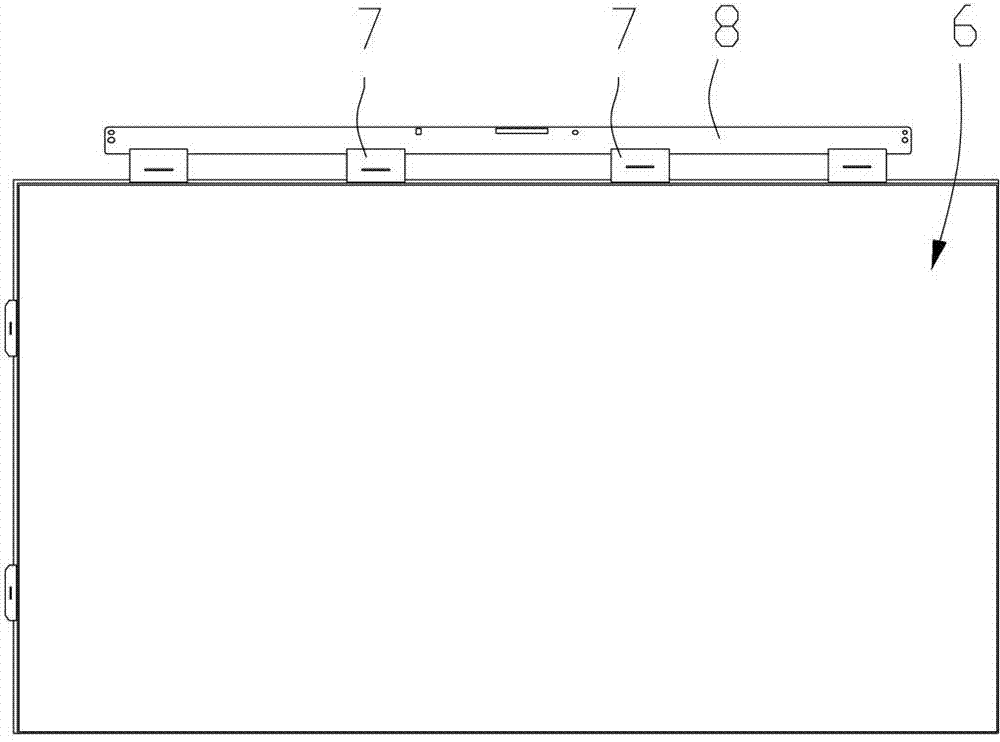

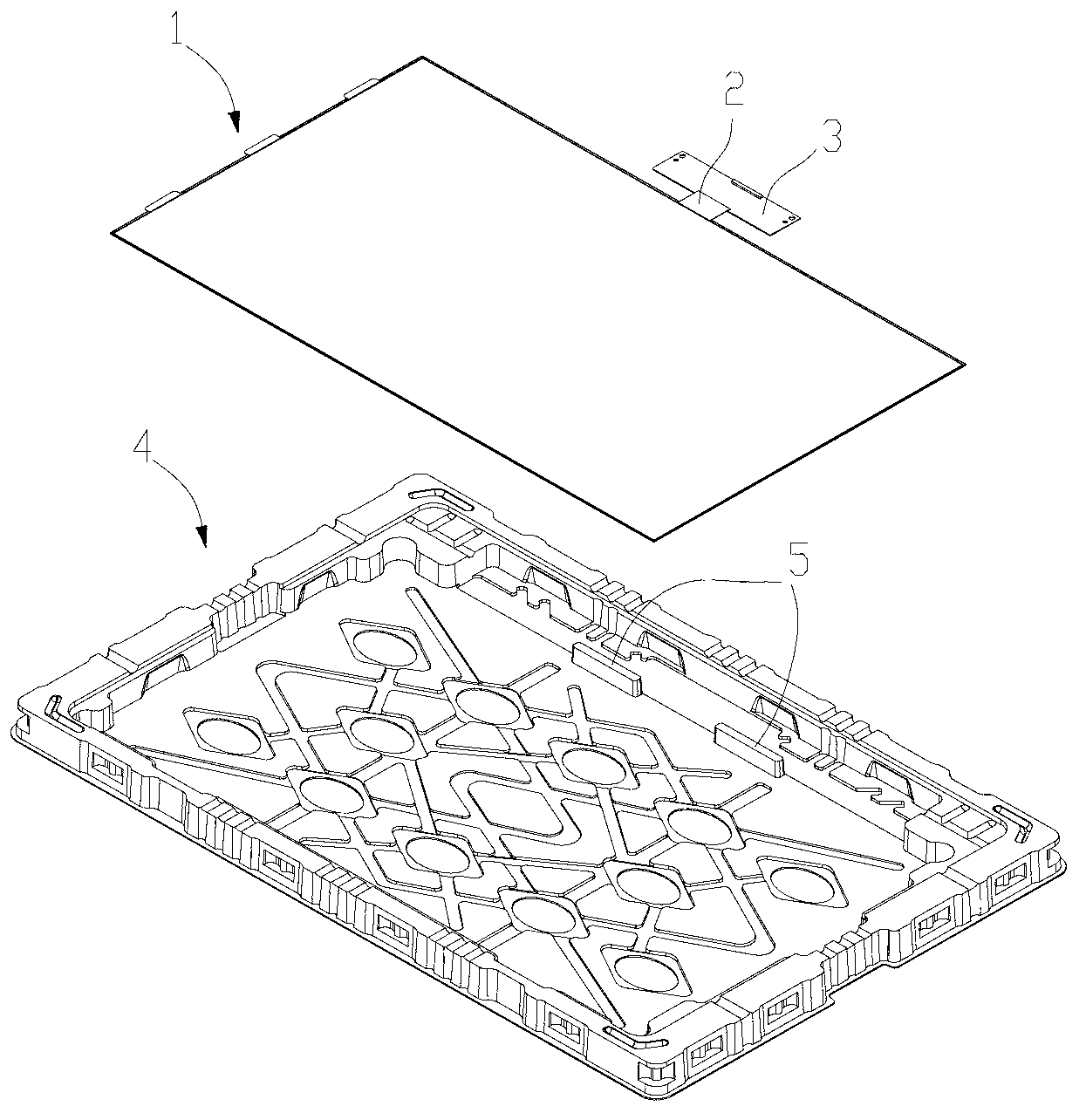

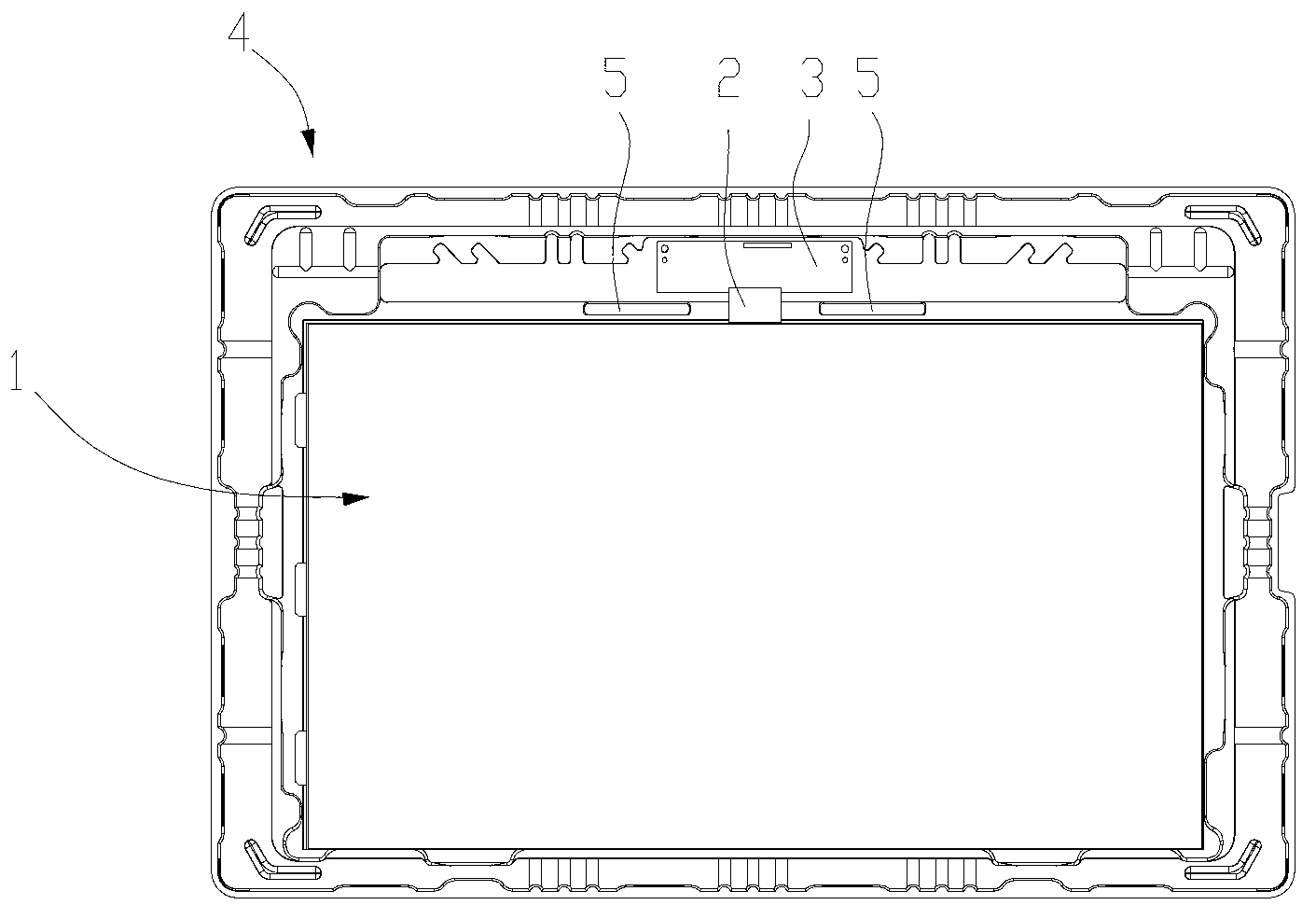

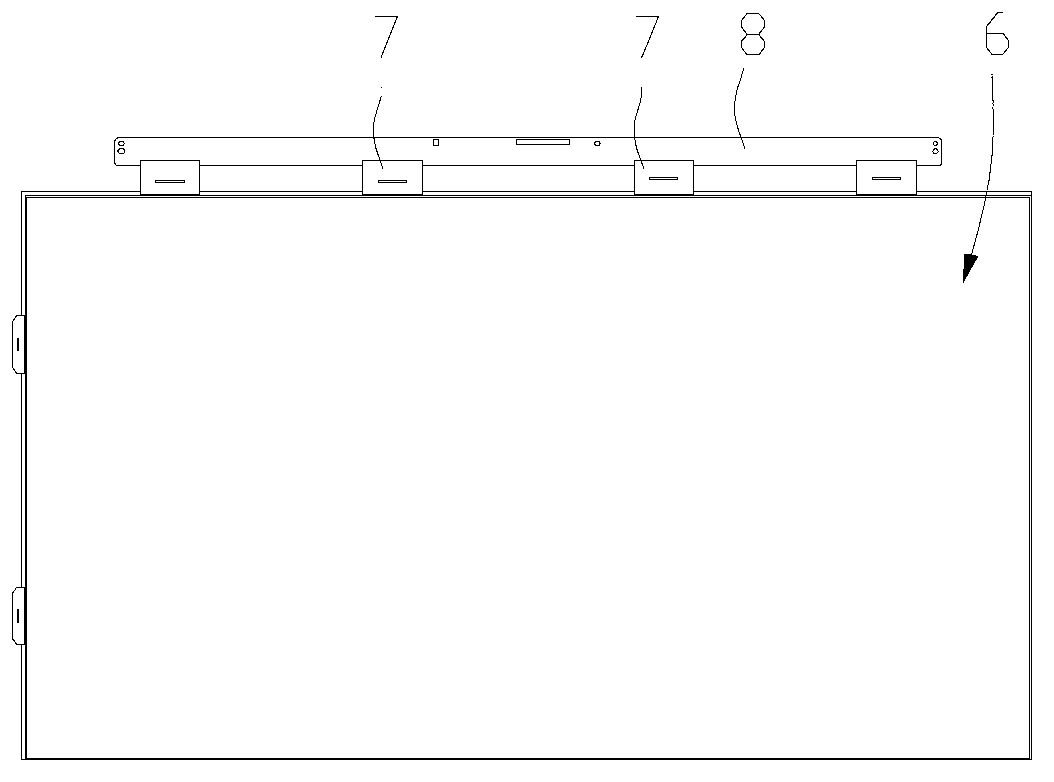

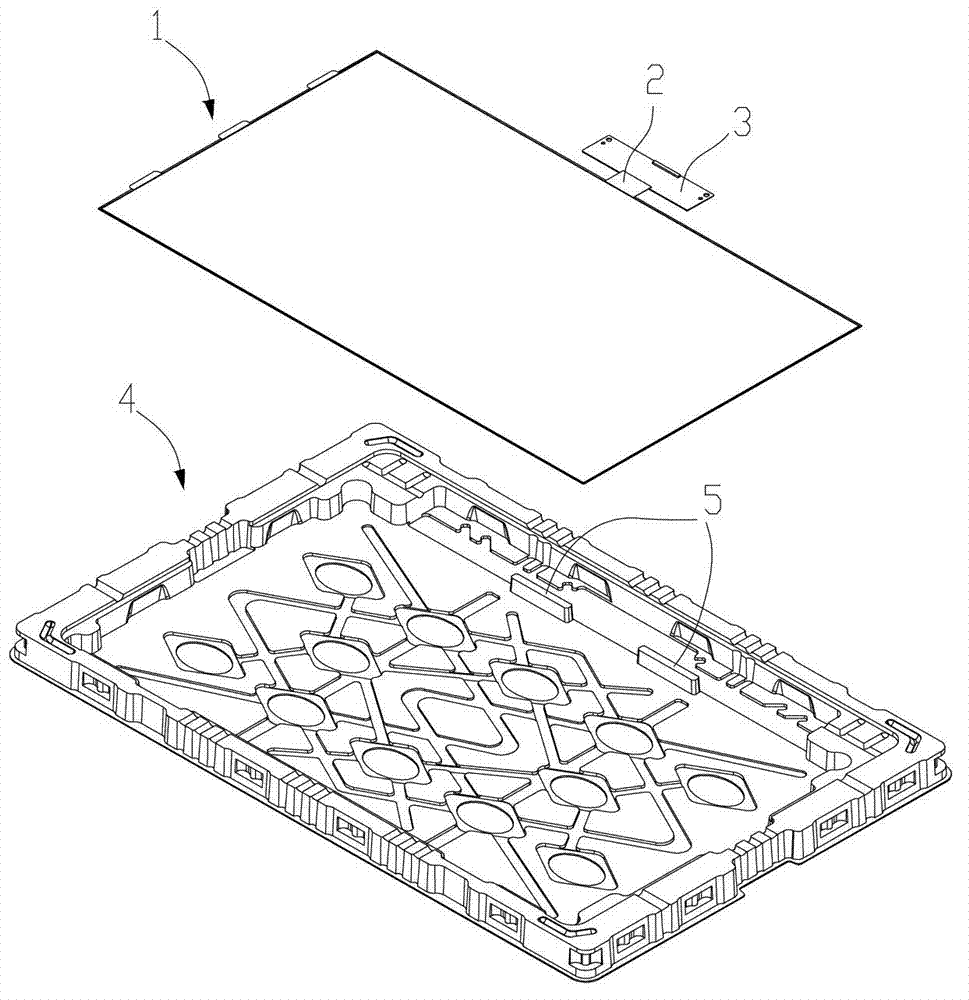

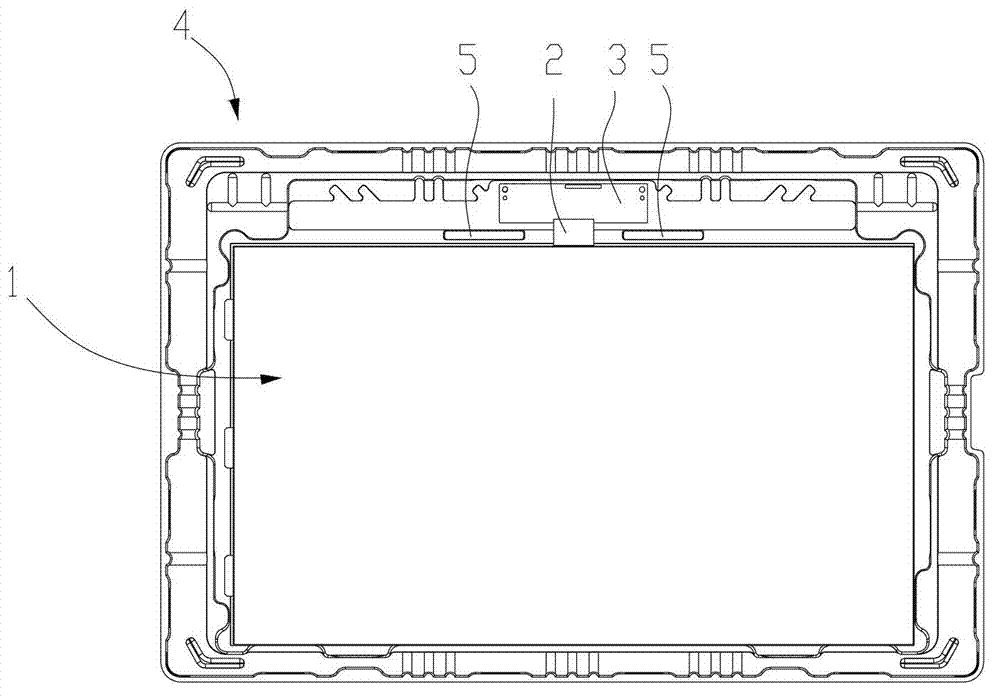

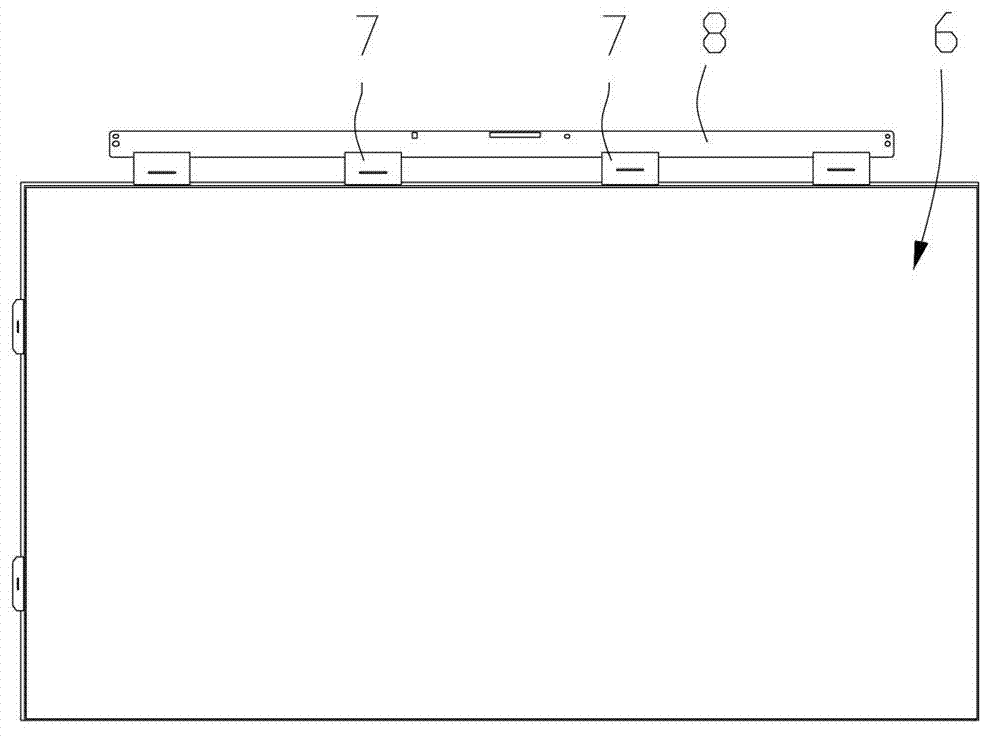

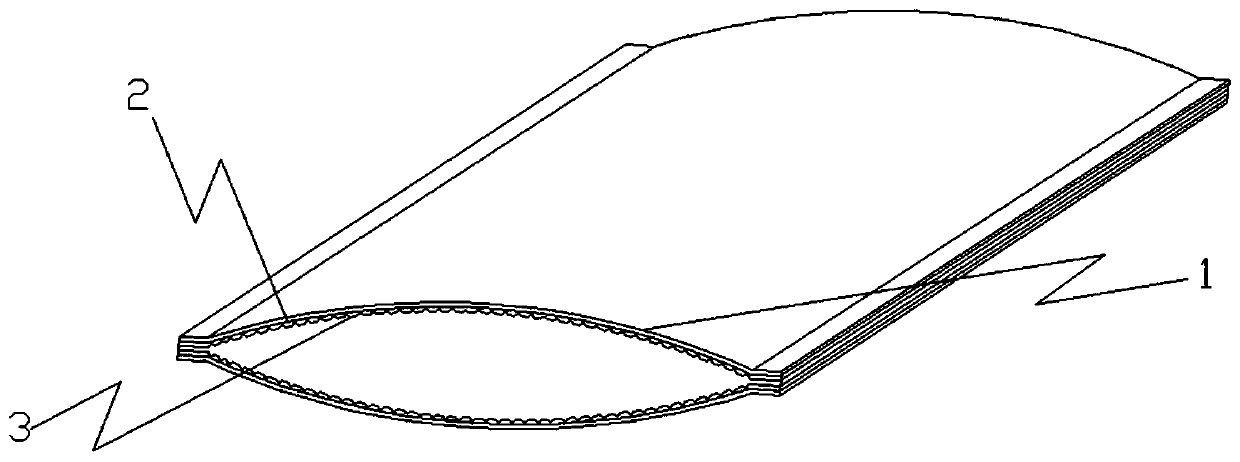

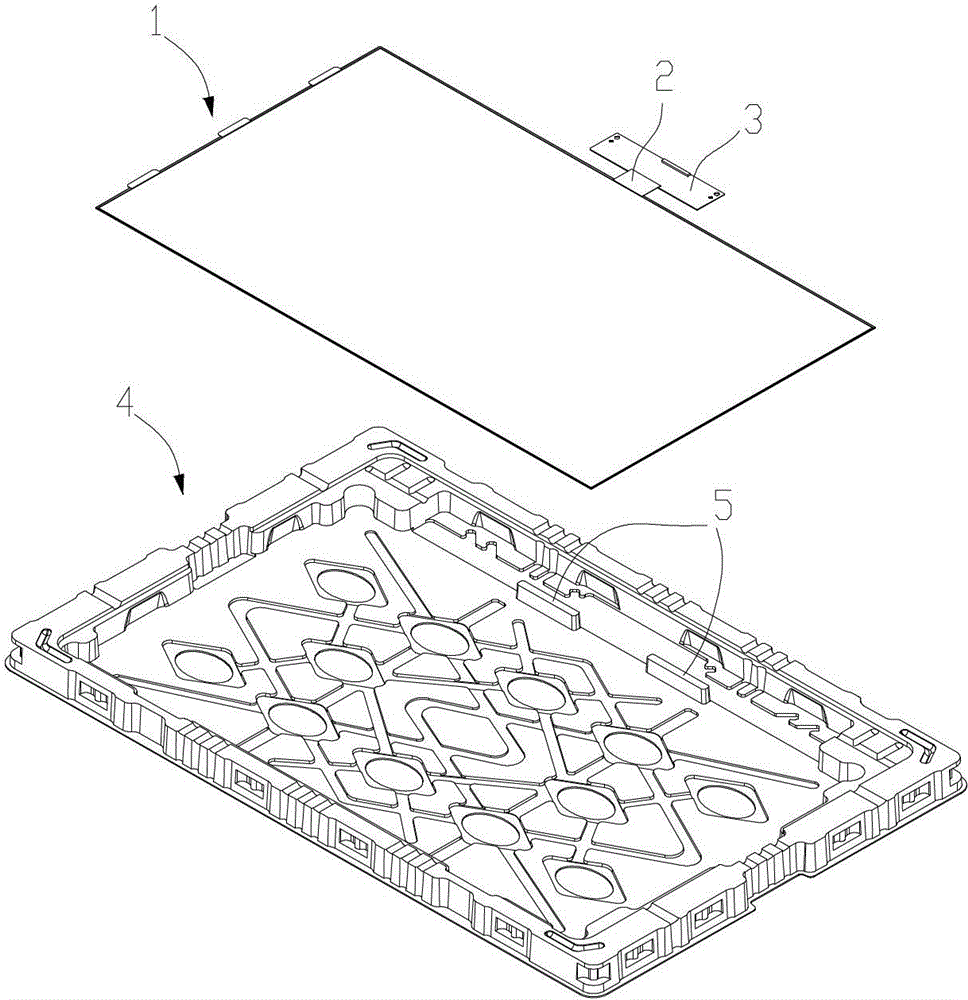

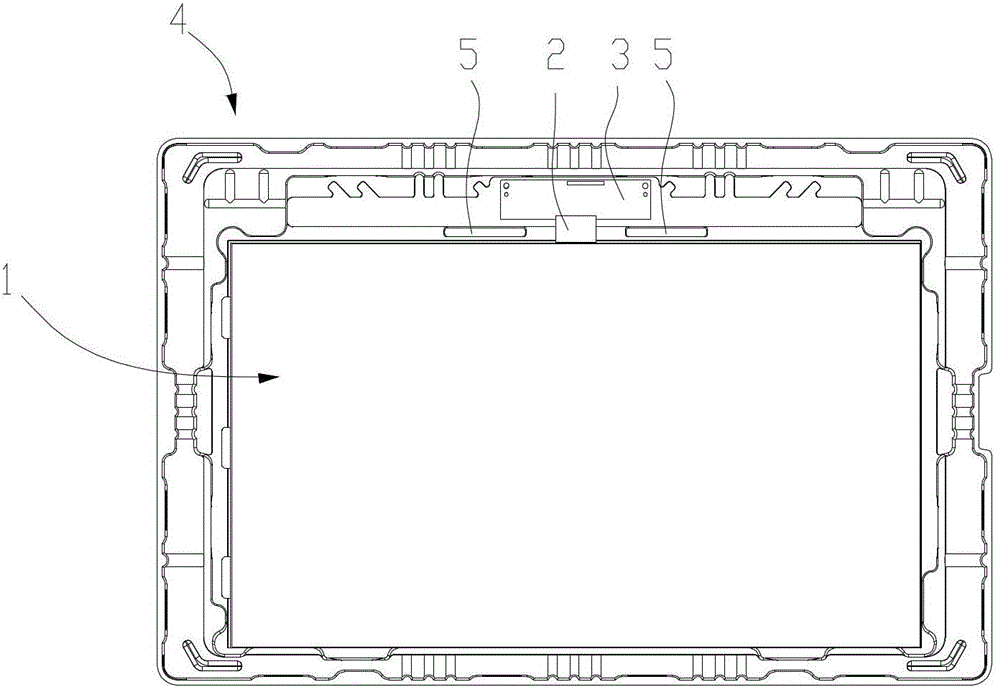

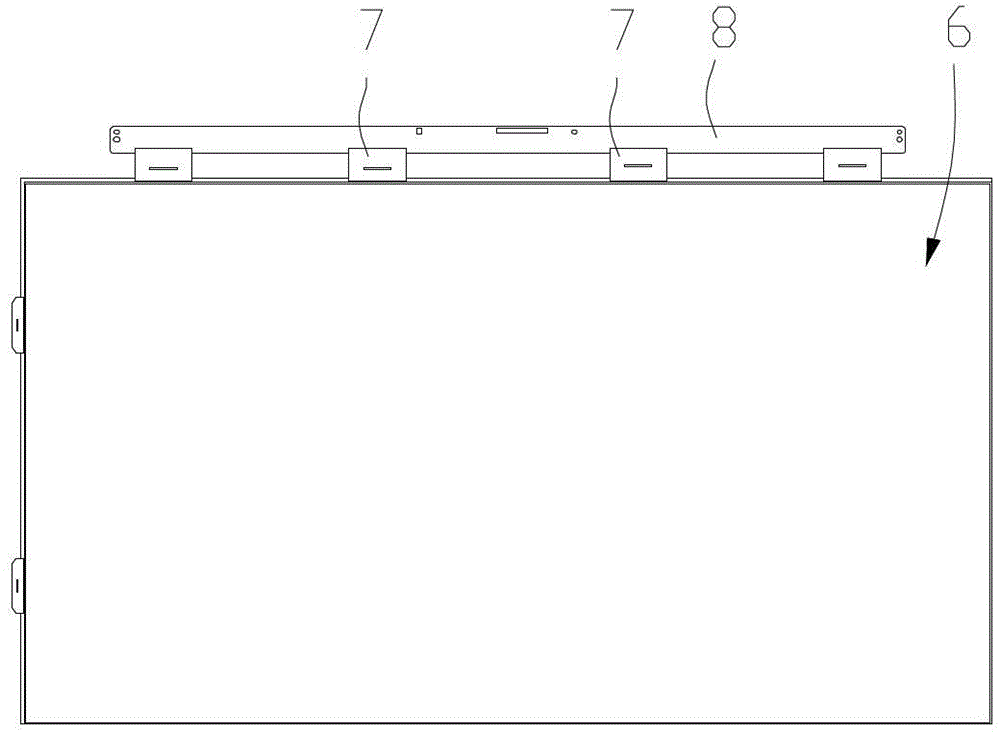

Tray with limit structure

ActiveCN103241469AImprove compatibilityComply with packaging requirementsRigid containersDamagable goods packagingChip on filmLiquid-crystal display

A tray with a limit structure is used for holding an Open Cell of a liquid crystal display. The tray comprises a tray body, and a groove for holding the Open Cell is arranged in the tray body. The tray with the limit structure is characterized by further comprising a fastener, the fastener comprises a fixing component connected with the tray body and a fastening component movably connected with the fixing component. The fastening is connected with the tray body in an adhering manner, can be mounted when needed or can be dismounted when not needed, and compatibility of the tray utilization is broadened. The fastening component is firstly lifted up around a hinged shaft before the Open Cell is dismounted, at this time, a PCB (printed circuit board) and a COF (chip on film) are in a relatively open state, the Open Cell is not blocked by external factors when being used, so that damages caused on the COF are prevented.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

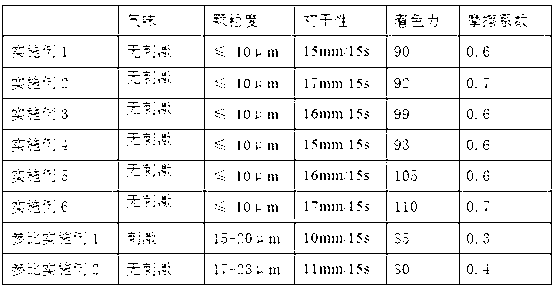

Water-soluble water-resistant printing ink for plastic woven sack and preparation thereof

The invention relates to a water-solubility printing ink and a method for preparing the same, in particular to a printing ink for a water-solubility waterproof plastic woven bag and a method for preparing the same. The printing ink for the water-solubility waterproof plastic woven bag is prepared by the following compositions in percentage by weight: 30 to 55 percent of crylic acid added rosin resin, 8 to 12 percent of nontoxic pigment, 12 to 20 percent of water, 8 to 12 percent of ammonia, 10 to 15 percent of pure acrylic emulsion, 3 to 6 percent of water-based wax, 0.1 to 1 percent of defoaming agent and 0.3 to 1 percent of flatting agent, which are in mass percentage. The printing ink solves the disadvantages of a solvent-type plastic woven bag after being printed by the printing ink has the influence of odor of the residual solvent; and a water-based woven bag after being printed has the poor water resistance, etc. The product can be widely used in the packaging printing of the plastic woven bag of grain, vegetable, tobacco, food, solid beverage and other industries, in particular to farm and sideline products, food and other aspects which relate to the packaging of hydrous products. The printed product can ensure safety and nontoxicity, can not produce the harm to human health and is a green and environment-friendly product.

Owner:浙江永在油墨有限公司

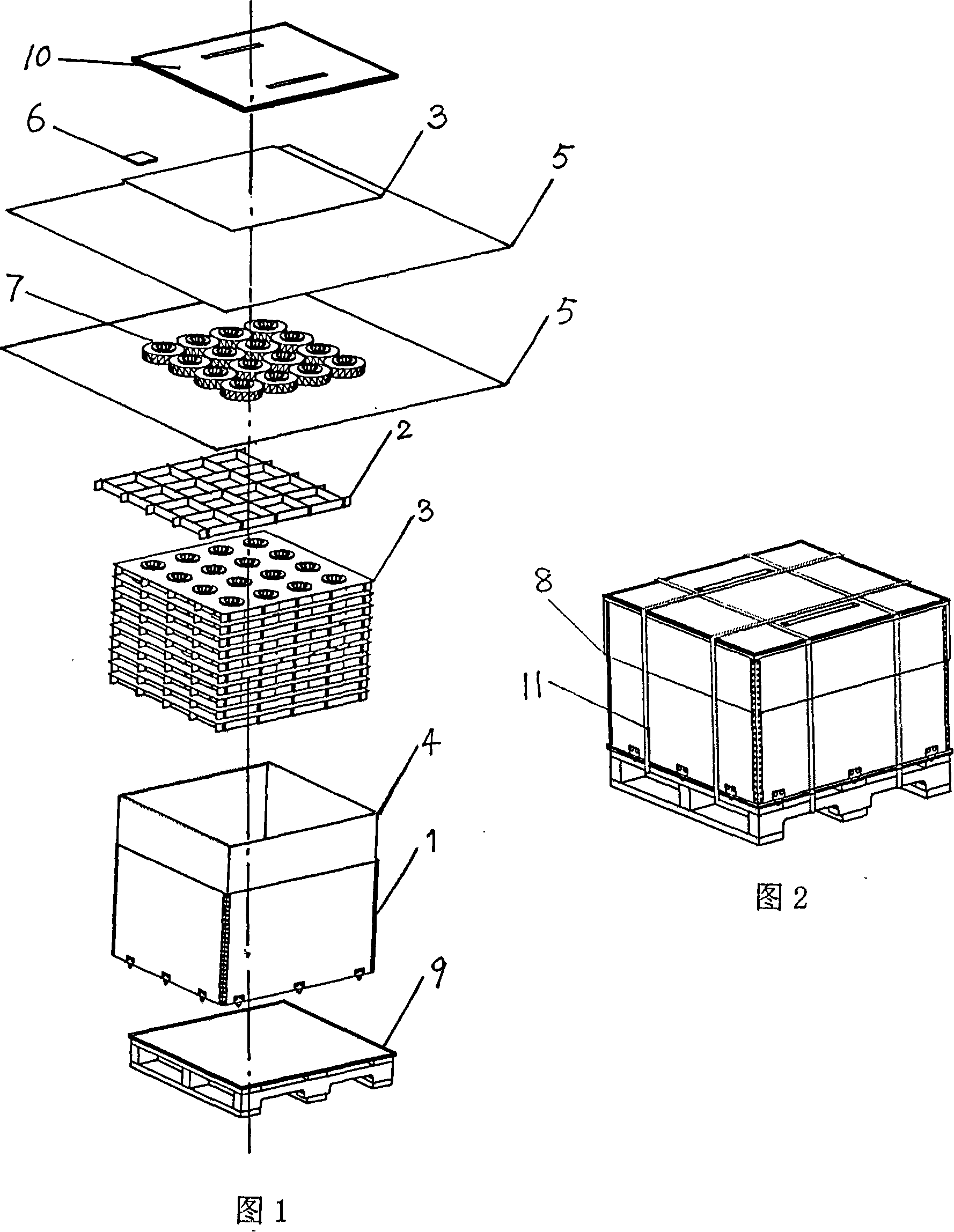

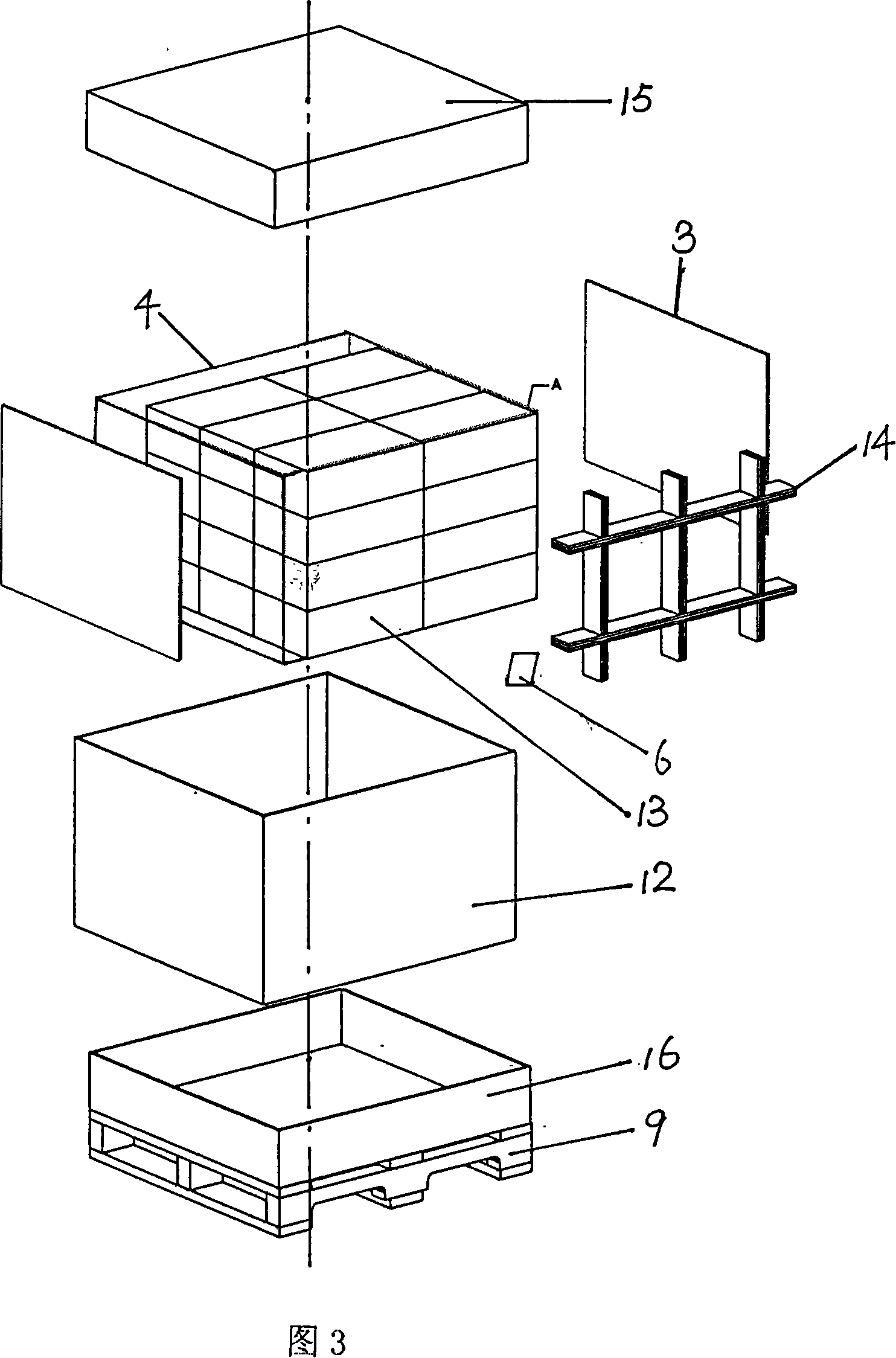

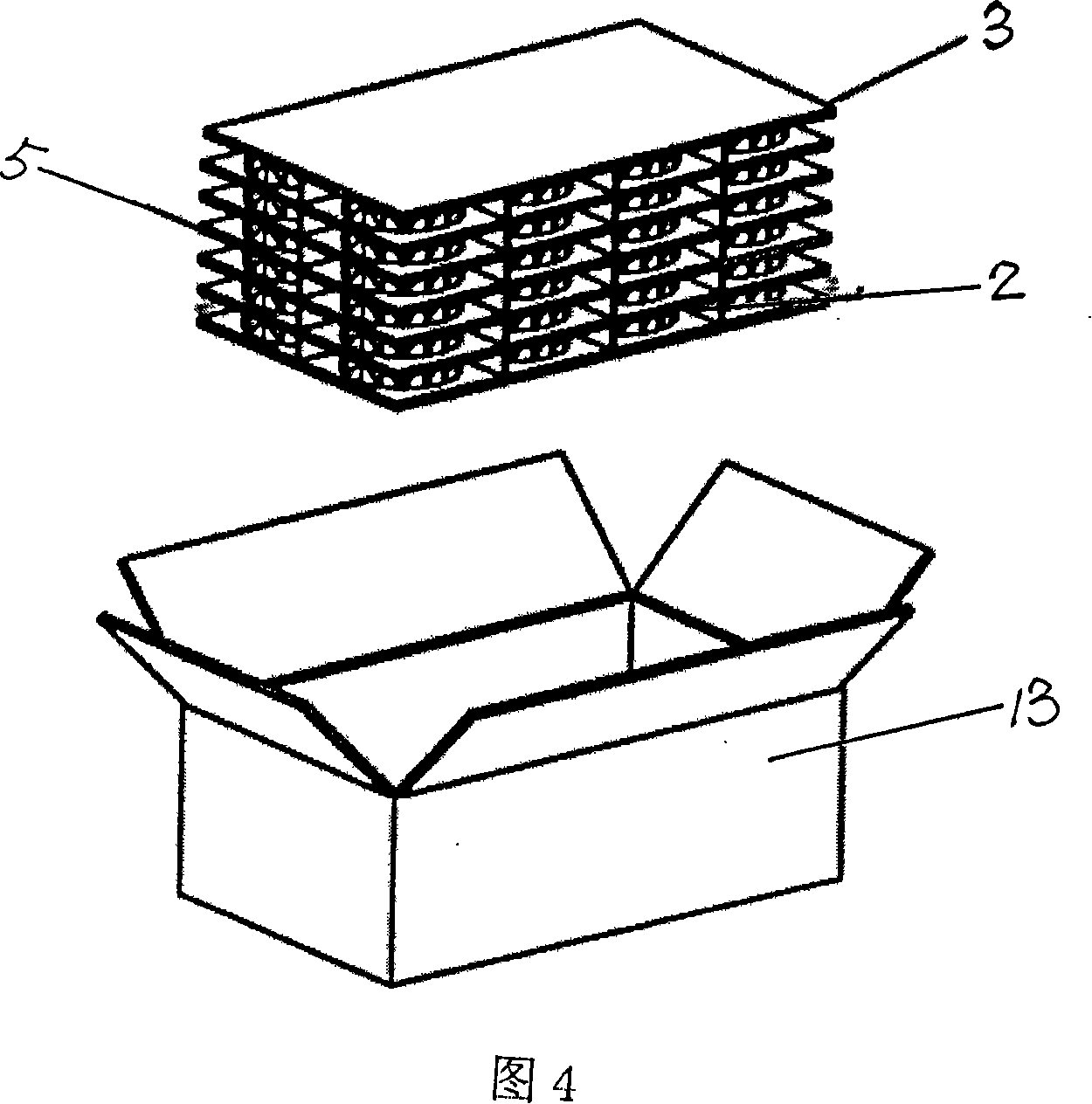

Rust prevention packaging method of metallic product

InactiveCN101108679AAvoid contactPrevent rust and corrosionRigid containersContainers with multiple articlesGas phaseEngineering

The invention belongs to the technology field of the metal product package, in particular to an anti-rust package method of the metal product. The invention solves the problems of poor anti-rust effect or high package cost existing in the anti-rust package of the current metal product. The procedure of the anti-rust package method of the metal product is as follows: an outer package is arranged with gas phase anti-rust bags inside, corrugated boards are rolled out; corrugated paper is added in to separate; gas phase anti-rust films are added; the metal product is filled; the gas phase anti-rust films are covered; the corrugated boards and dryers are added; gas phase anti-rust bags are arranged; the outer package is closed and is externally covered with PE rainproof films and PET is bound. The invention has the beneficial effects of oil-saving, environmental protection, anti rust, firm structure, simple technic, long anti-rust period and high reliability.

Owner:SHANXI DATONG GEAR GROUP

Universal binder resin for water-based plastic surface printing ink, preparation method thereof and printing ink using binder resin

ActiveCN103183831AReduces pungent odorsStrong adhesionInksNatural resin chemical modificationPolymer sciencePrinting ink

The invention specifically relates to a universal binder resin for a water-based plastic surface printing ink, a preparation method thereof and a printing ink using the binder resin, belonging to the field of printing inks. The binder resin provided by the invention is prepared through the following steps: subjecting a modified rosin resin and an amide oligopolymer to a condensation reaction so as to produce an intermediate product with a carboxyl group; allowing the intermediate product and a resin containing multiple carboxyl groups to undergo polymerization; and carrying out amination so as to obtain the water-soluble binder resin. Because of introduction of an acylamino group, the binder resin has good adhesion, luster and printing adaptability on a variety of plastic film substrates. According to the invention, the preparation method for the binder resin is simple; the prepared printing ink has good printing adaptability and is applicable to surface printing of a variety of plastic film substrates, and since water is used as a solvent, the printing ink has no irritant gas and is green and environment-friendly.

Owner:广东天龙油墨有限公司

Special BOPP film for cold transfer cigarette label paper and preparation method of BOPP film

InactiveCN104210205ASmooth packaging processBroad machine applicabilitySynthetic resin layered productsMasterbatchAntistatic agent

The invention discloses a special BOPP film for a cold transfer cigarette label paper and a preparation method of the BOPP film. A direct co-extrusion composite way of a three-layer structure is adopted, and according to the formula, each layer of raw material comprises the following components in parts by weight: 85-99 parts of upper surface copolymer polypropylene, 1-15 parts of slipping anti-sticking agent master batch, 55-80 parts of core layer homopolymer polypropylene, 15-30 parts of stiffening agent maser batch, 5-15 parts of slip-antistatic agent master batch, 65-89 parts of lower surface copolymer polypropylene, 10-20 parts of slipping agent master batch and 1-15 parts of anti-sticking agent master batch. The produced BOPP film has relatively wide operation applicability, good stiffness and high elasticity modulus by optimal raw materials and process, and is capable of reducing the contact surface of the BOPP film and the cold transfer cigarette label as a special package film for the cold transfer cigarette label paper, and therefore, the film is effectively prevented from being fitted with the cigarette label to avoid generating the 'watermark' phenomenon during packaging, and compared with an existing BOPP film, the BOPP film has the advantages that the packaging efficiency and the packaging quality are obviously improved.

Owner:ZHANJIANG PACKAGING MATERIAL ENTERPRISES

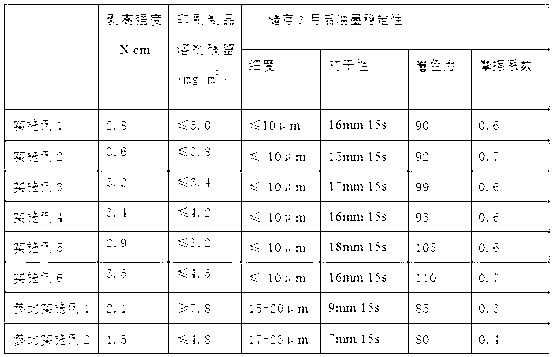

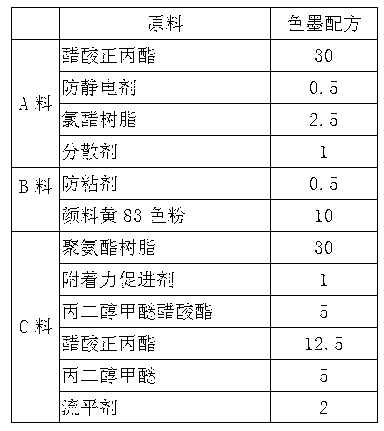

Lipophilic intaglio compound printing ink and preparation method thereof

The invention relates to intaglio compound printing ink, in particular relates to lipophilic polyurethane printing ink and a preparation method thereof, and belongs to the field of printing ink. In order to overcome the technical defects of big smell, more residual solvent and poor resin fastness of the printing ink in the prior art, the invention provides the lipophilic intaglio compound printing ink and the preparation method thereof. The lipophilic intaglio compound printing ink has excellent early dry performance and tinting strength, is very suitable for automatic packaging and has a good industry popularization value, and the friction coefficient is between 0.6 and 0.7.

Owner:BAUHINIA VARIEGATA INK & CHEM (ZHONGSHAN) LTD

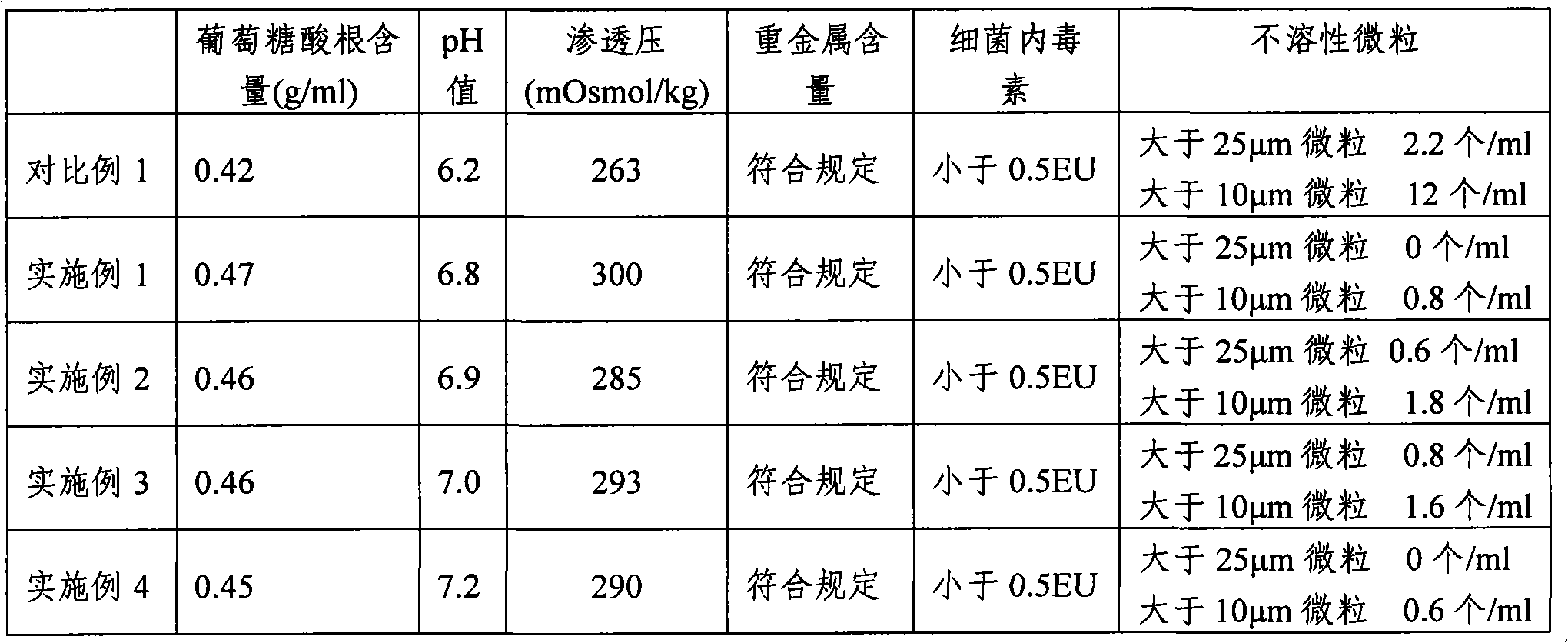

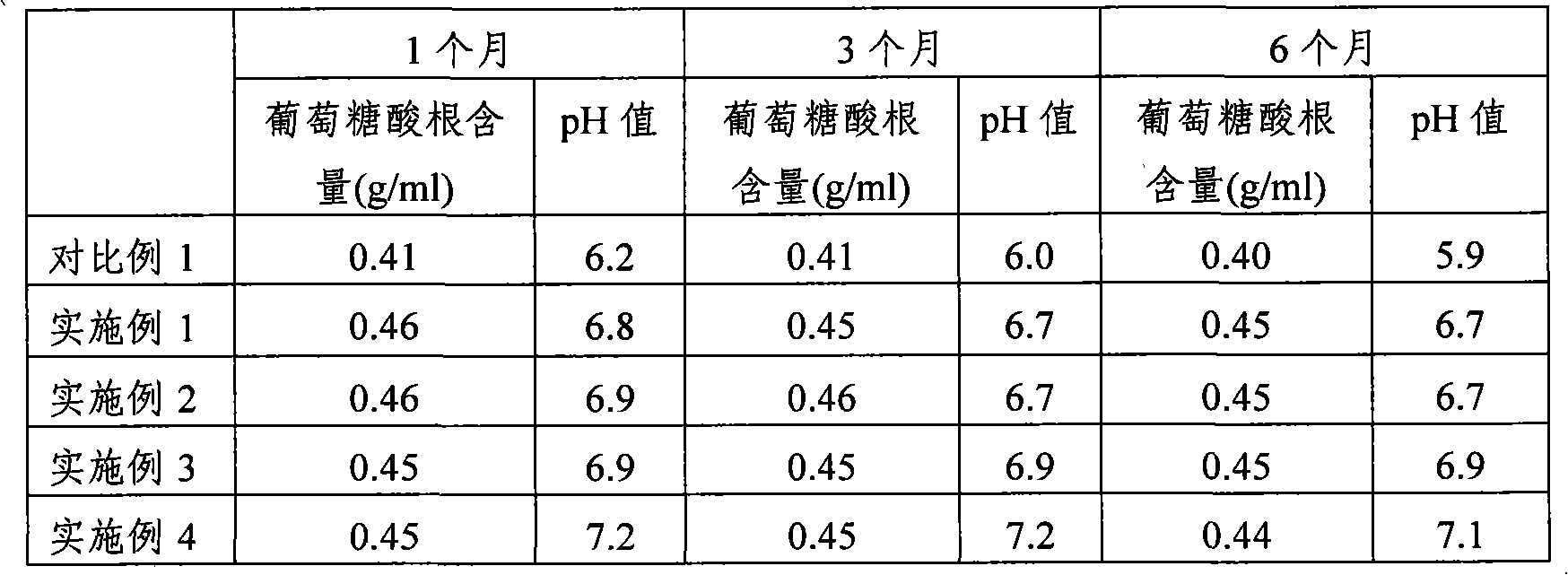

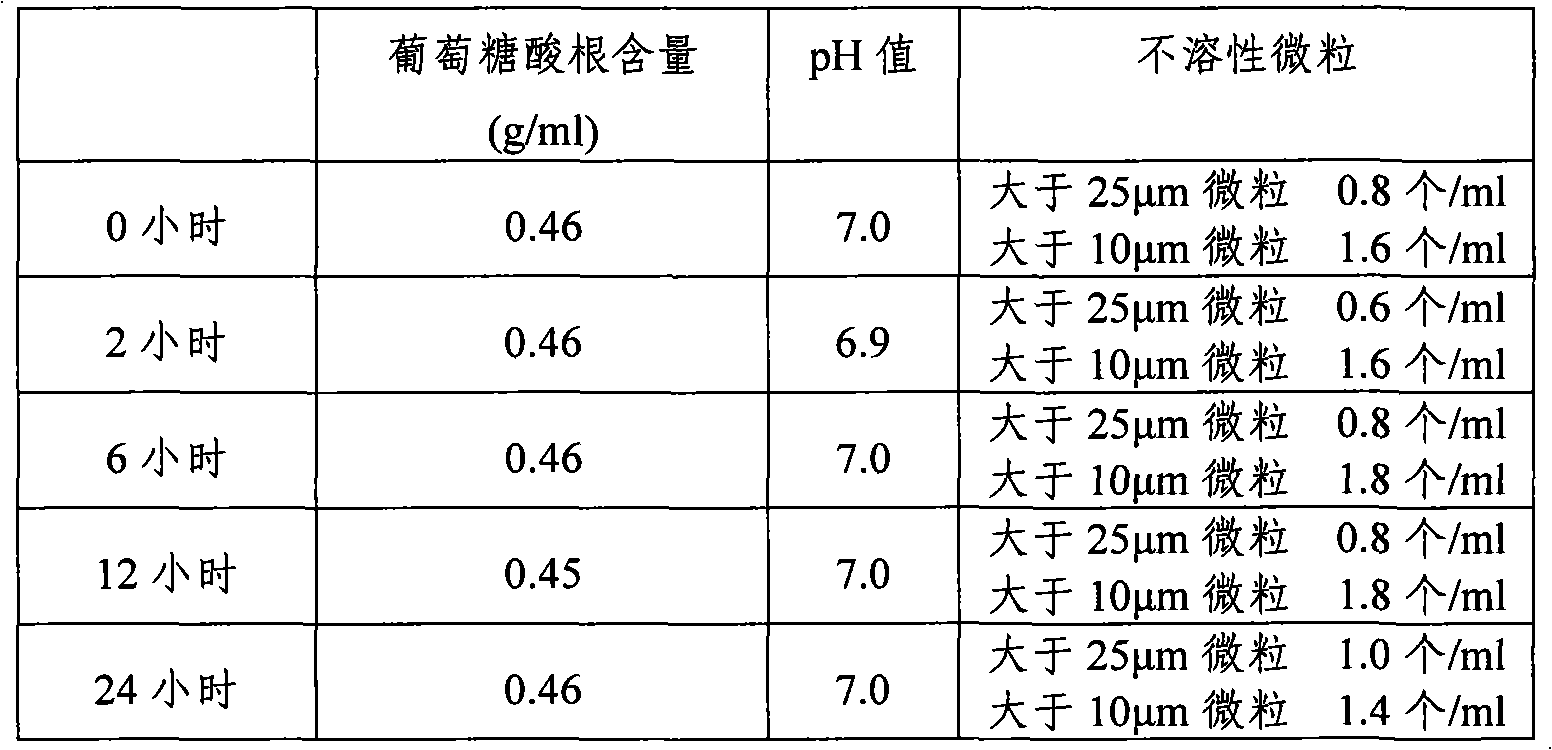

Solution for surgery and endoscope washing and preparation method thereof

InactiveCN102836171AEnsure safetySuitable for transportationSurgical drugsPharmaceutical delivery mechanismPolypropyleneChemistry

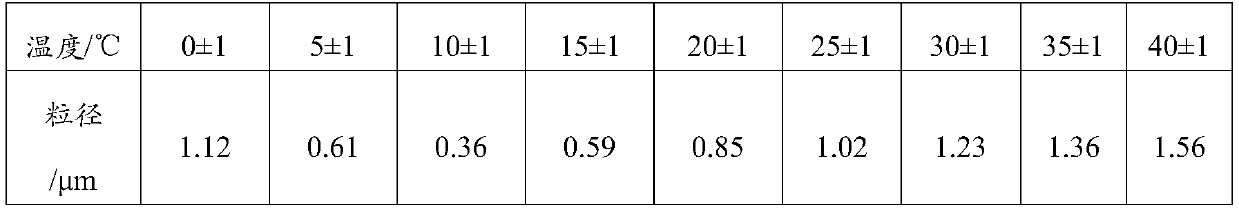

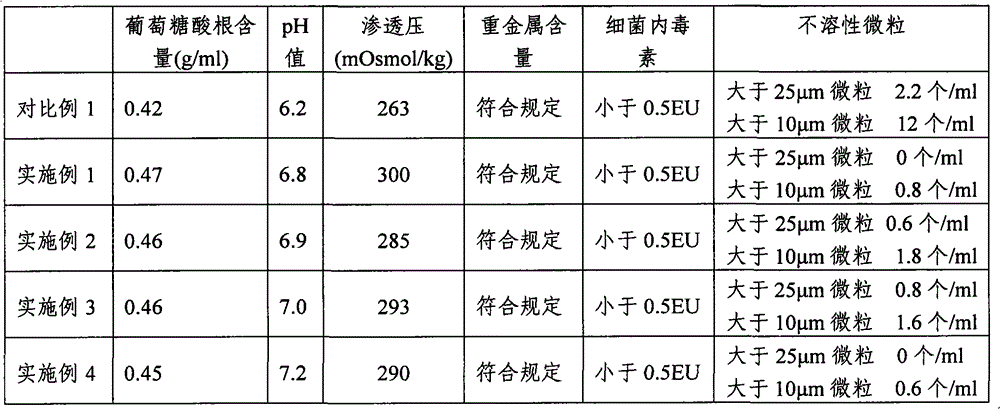

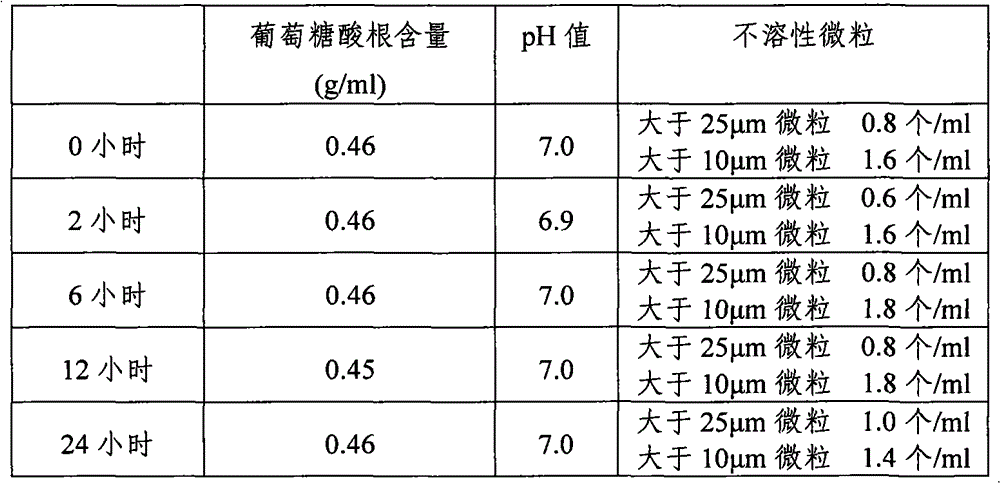

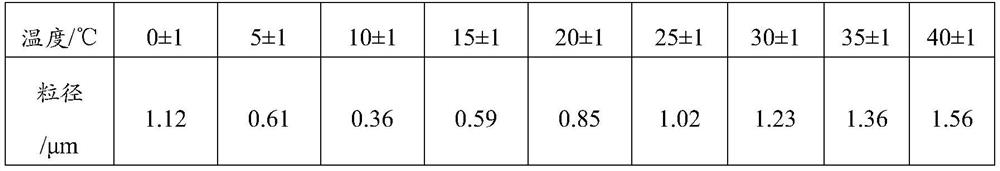

The invention relates to a solution for surgery and endoscope washing and a preparation method of the solution. Each 100mL of the solution contains 526mg of sodium chloride, 368mg of sodium acetate, 502mg of sodium gluconate, 37mg of potassium chloride and 30mg of magnesium chloride; and the pH value of the solution is 6.7 to 7.2 and the osmotic pressure is 280 to 300mOsmol / kg. The production process of the solution provided by the invention is managed according to the relevant quality standards of an injection, and the bacterial endotoxins and the insoluble particles completely accord with the requirements of the injection; and moreover, the polypropylene infusion bottles are served as an inner packing material, the contents and the packing material have good biocompatibility, so that the solution is convenient for clinical use and transportation and storage.

Owner:北京金康驰医药投资有限公司

Tray with limiting structure

ActiveCN103241470AImprove compatibilityComply with packaging requirementsRigid containersDamagable goods packagingEngineeringPrinted circuit board

A tray with a limiting structure is used for packaging an Open Cell of a liquid crystal screen and comprises a tray body. A groove for placing the Open Cell is arranged in the tray body. The tray is characterized by further comprising a limiting assembly, and the limiting assembly is connected to a body base plate of a gap between a printed circuit board (PCB) of the Open Cell and a liquid crystal box. The limiting assembly is connected with the tray body, and can be installed when in need or can be taken down when not in need, tray using compatibility is expanded, and the packaging requirements of an Open Cell A and an Open Cell B are met. The position of a limiting block in the limiting assembly is adjustable simultaneously and pull between the Open Cell and the limiting assembly is effectively avoided.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

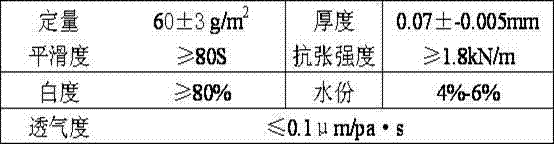

Aluminum-free anti-counterfeiting lining paper for cigarettes and production method thereof

InactiveCN102587206ALow priceNothing producedCoatings with pigmentsSpecial paperPolyvinyl alcoholAdhesive

The invention provides an aluminum-free anti-counterfeiting lining paper for cigarettes and a production method thereof. The lining paper is composed of an anti-counterfeiting paper layer, a coating layer and an aqueous printing oil layer. The technical indexes are as follows: the fixed quantify is 60+ / -3 g / m<2>; the thickness is 0.07+ / -0.005 mm; the flatness is more than or equal to 80 S; the tensile strength is more than or equal to 1.8 kN / m; the whiteness is more than or equal to 80%; the water content is 4-6%; and the air permeability is less than or equal to 0.01 micron / Pa.s. The production method comprises the following steps of: firstly preparing a coating; and then, coating the prepared coating on front and back sides of anti-counterfeiting paper on a coating machine, so as to prepare a product. According to the production method, the anti-counterfeiting paper is used as basic paper and an anti-counterfeiting function is organically combined with the lining paper for the cigarettes, thereby achieving the anti-counterfeiting effect and greatly reducing the cost. The formula of the coating used in the preparation method is unique and a main paint part is papermaking porcelain clay which is widely applied to the papermaking industry and is low in price and an adhesive is polyvinyl alcohol and has no extraneous odor or toxicity; in the production process, no organic solvent is used and no pollutant is generated, thereby protecting environment. Non-ferrous metal such as aluminum foils, aluminum powder and copper powder, is not used, so that the product cost is low, the energy consumption is low, and ideals of energy saving and environmental protection and low-carbon lifestyle are realized.

Owner:杜荣安 +2

Production method of biomass industrial cushion packaging product

The invention discloses a production method of a biomass industrial cushion packaging product. The method is characterized by including the following technological steps: adding straw fiber, starch and auxiliary modifier into the respective processing device; introducing straw fiber and auxiliary modifier into a same device and mixing; introducing starch into a gelatinization container; adding hot water and stirring into a slurry starch paste; introducing the starch paste into the device containing the straw fiber and the auxiliary modifier; and stirring uniformly and conveying to a wet material storage bin for a next production process. The method can greatly reduce the cost of raw materials; and the full biomass synthetic ingredient can be used in production of a magnetic soft iron element transfer pallet packaging product, which has excellent performance, reliable degradation, low cost, and extremely broad industrial promotion value.

Owner:山东九发生物降解工程有限公司

Transfer paint producing no regenerated benzene after UV (ultraviolet) printing and preparation method thereof

InactiveCN104497749AReduce contentReduce manufacturing costCellulose coatingsPolyurea/polyurethane coatingsBenzeneWater based

The invention discloses transfer paint producing no regenerated benzene after UV (ultraviolet) printing, which comprises the following components in parts by weight: 25-35 parts of water-based polymer resin, 8-12 parts of water-based cellulose, 10-20 parts of cosolvent, 30-40 parts of deionized water, 0.1-3 parts of pH regulator, 0.2-0.3 part of leveling agent, 0.05-0.1 part of defoaming agent and 0.05-0.1 part of releasing agent. The transfer paint prepared according to the above formula overcomes defects in the prior art, thus providing the safe, non-toxic and low-cost transfer paint producing no regenerated benzene after UV printing; and the transfer paint can be directly used instead of the existing solvent type laser transfer paint.

Owner:湖北绿新环保包装科技有限公司

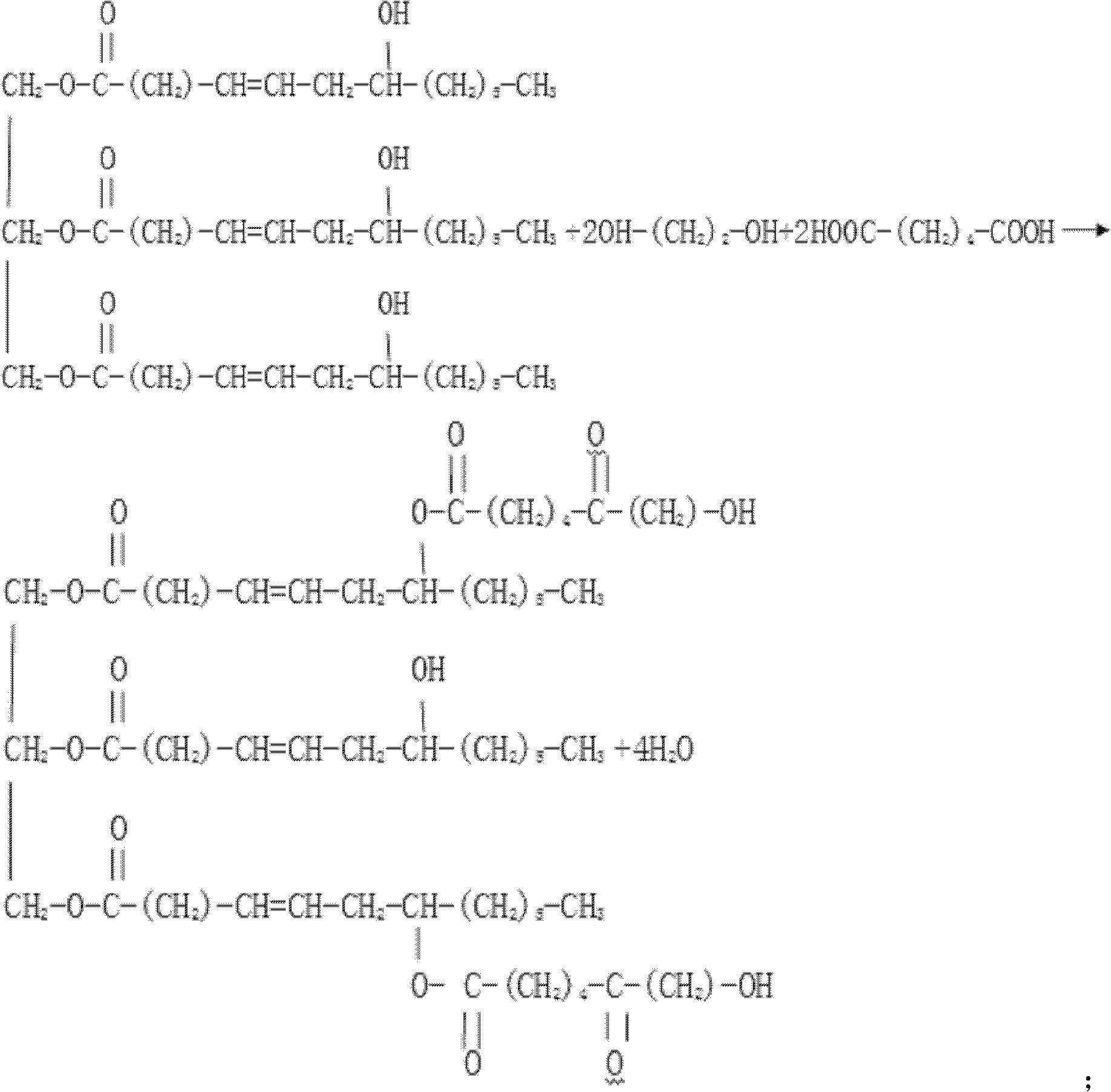

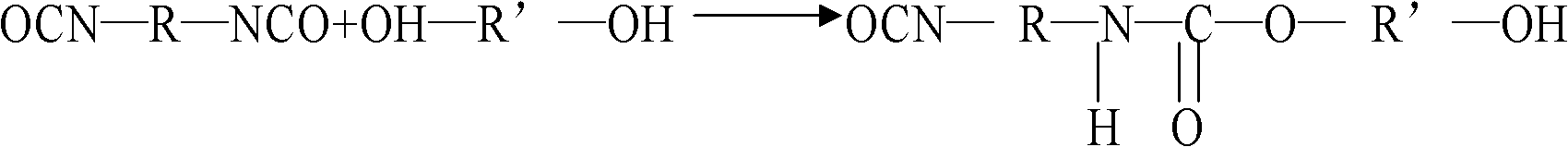

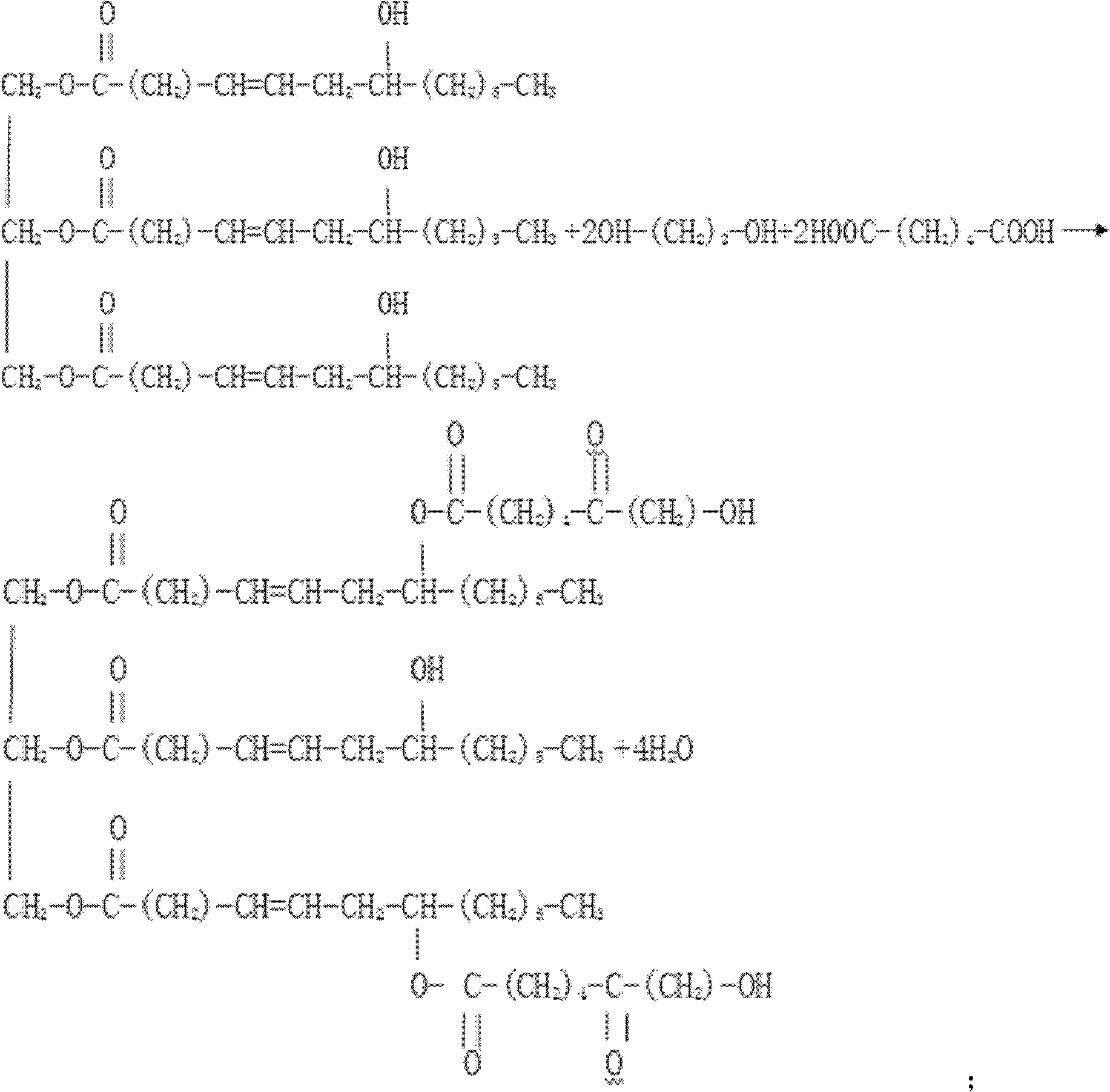

Trans-form double-component solvent-free polyurethane adhesive for composite film and preparation method thereof

InactiveCN107779162ANo emissionsComply with packaging requirementsNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterPolyurethane adhesive

The invention discloses a trans-form double-component solvent-free polyurethane adhesive for a composite film and a preparation method thereof. The adhesive is composed of a component A obtained by mixing polyester glycol and a silane coupling agent and an isocyanate-terminated component B, wherein the functional group mol ratio of the component A to the component B is 1 to (1.5 to 2.0). Accordingto the double-component solvent-free polyurethane adhesive disclosed by the invention, the composition is opposite to an existing solvent-free composition; the component A is changed into a hydroxylcomponent and the component B is changed into an isocyanate component; the trans-form double-component solvent-free polyurethane adhesive is environmentally friendly and no solvent is discharged; thetrans-form double-component solvent-free polyurethane adhesive is suitable for structures including a compound aluminum foil, aluminum foil water boiling, steaming, aluminum-plating water boiling andthe like; and the compound strength and other properties of the trans-form double-component solvent-free polyurethane adhesive are the same as those of a solvent type polyurethane adhesive, and the requirements of a soft package enterprise and food packages are met.

Owner:BEIJING COMENS NEW MATERIALS

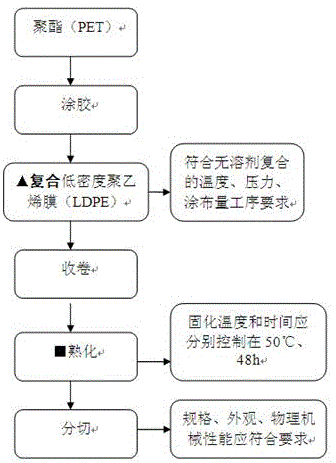

Polyester/low-density polyethylene composite film for packaging and preparation method of polyester/low-density polyethylene composite film

InactiveCN104476881AImprove adhesionNo leachable substancesSynthetic resin layered productsLaminationLow-density polyethylenePolyester

The invention discloses a polyester / low-density polyethylene composite film for packaging and a preparation method of the polyester / low-density polyethylene composite film. The polyester / low-density polyethylene composite film is mainly characterized by comprising a polyethylene terephthalate film, a low-density polyethylene film and a composite adhesive. The preparation method comprises steps as follows: after a polyester film is coated with an adhesive, the polyester film and the low-density polyethylene film are laminated and composited to form the polyester / low-density polyethylene composite film for packaging, and the polyester / low-density polyethylene composite film for packaging is obtained through one-time laminating and composite forming. The used raw materials are easy to degrade, solvent-free composition is adopted, and the film doesn't contain benzene homologs and derivate and is environment-friendly and healthy.

Owner:QIYANG WUZHOU PHARMA PACKAGING

Universal binder resin for water-based plastic surface printing ink, preparation method thereof and printing ink using binder resin

ActiveCN103183831BStrong coloring powerHigh glossInksNatural resin chemical modificationWater basedPrinting ink

The invention specifically relates to a universal binder resin for a water-based plastic surface printing ink, a preparation method thereof and a printing ink using the binder resin, belonging to the field of printing inks. The binder resin provided by the invention is prepared through the following steps: subjecting a modified rosin resin and an amide oligopolymer to a condensation reaction so as to produce an intermediate product with a carboxyl group; allowing the intermediate product and a resin containing multiple carboxyl groups to undergo polymerization; and carrying out amination so as to obtain the water-soluble binder resin. Because of introduction of an acylamino group, the binder resin has good adhesion, luster and printing adaptability on a variety of plastic film substrates. According to the invention, the preparation method for the binder resin is simple; the prepared printing ink has good printing adaptability and is applicable to surface printing of a variety of plastic film substrates, and since water is used as a solvent, the printing ink has no irritant gas and is green and environment-friendly.

Owner:广东天龙油墨有限公司

High chemical resistance borosilicate glass and purpose thereof

InactiveCN101717189BComply with packaging requirementsReduce manufacturing costPharmaceutical containersMedical packagingWorking temperatureChemical resistance

The invention discloses high chemical resistance borosilicate glass, comprising the following components based on oxides in percentage by weight: 71-75 SiO2, 3-6 Al2O3, 8-10 B2O3, 4-10 Na2O and 0-2.5 K2O, 0-1.2 CaO, 0-1 MgO, 1-3 BaO and 0-0.3 CeO2, wherein Na2O+K2O ranges from 7 to 10, and CaO+MgO ranges from 0 to 1.2. The invention has the following advantages: 1. As2O3, Sb2O3, BaSO4 and other harmful substances are not used in constituents, and the borosilicate glass can be used as a material for packing medicines; and 2. tested by experiments, the high chemical resistance borosilicate glass prepared from the constituents by the traditional production equipment has the coefficient of heat expansion ranging from 5.0*10<-6> K<-1> to 6.0*10<-6> K<-1>, the inversion temperature Tg ranging from 520 DEGC to 572 DEGC, the softening point ranging from 765 DEGC to 782 DEGC, the working temperature ranging from 920 DEGC to 1200 DEGC and the density ranging from, 2.32 g / cm<3> to 2.5g / cm<3>, which meet the requirement on medicinal packing and reduces the production cost.

Owner:SHANDONG LINUO NEW MATERIAL

Application of water metal-paint on special package steel tank

InactiveCN1483641AReduce manufacturing costComply with packaging requirementsFlexible coversWrappersLacquerMetal

The present invention is characterized by that the water metal paint can be spray-coated on the internal and external surfaces of steel barrel so as to produce the environment-protecting type coating light special packaging steel barrel, and the paint film quality of the environment-protecting steel barrel can completely meet the requirements for packaging steel barrel, and the quality of the steel barrel also can meet the packaging requirements for railway transportation and dangerous chemical cargo ocean transportation.

Owner:东莞振华泰丰实业发展有限公司

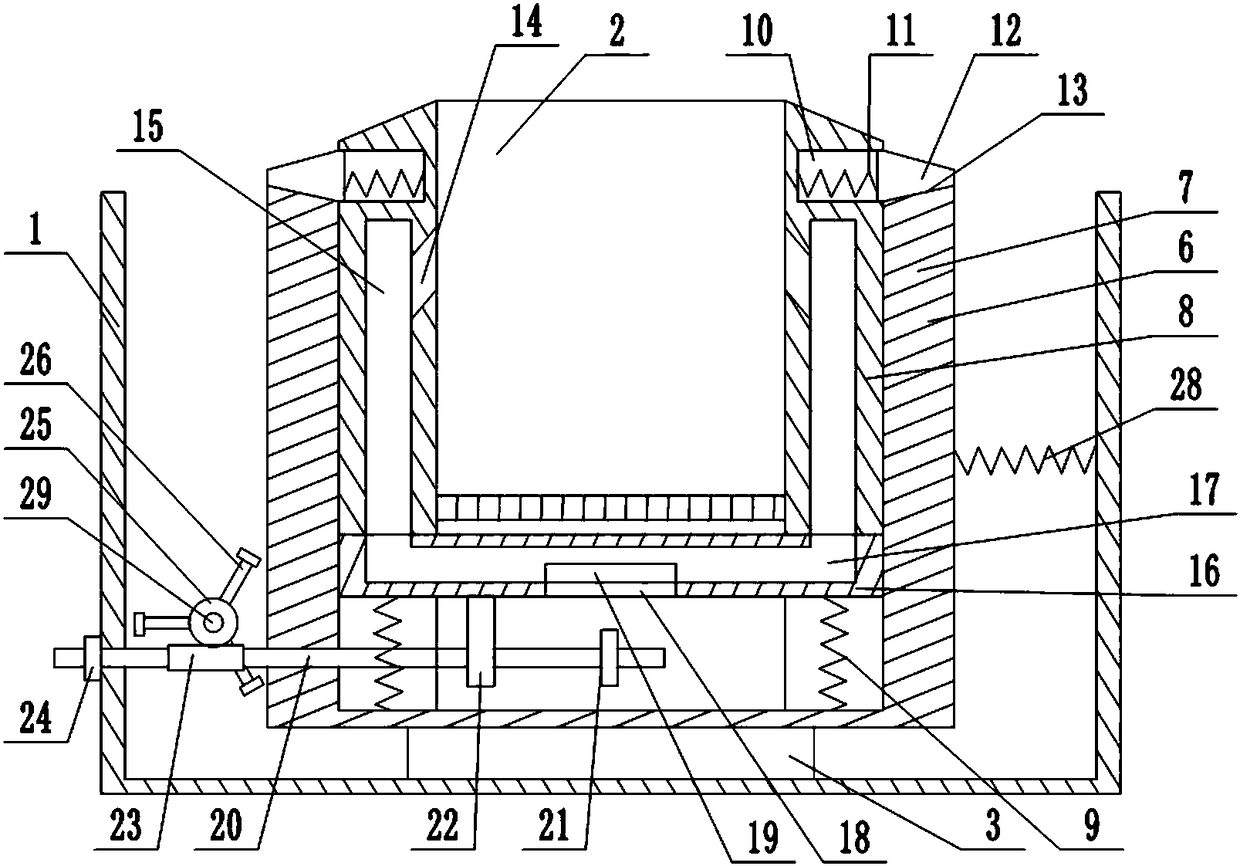

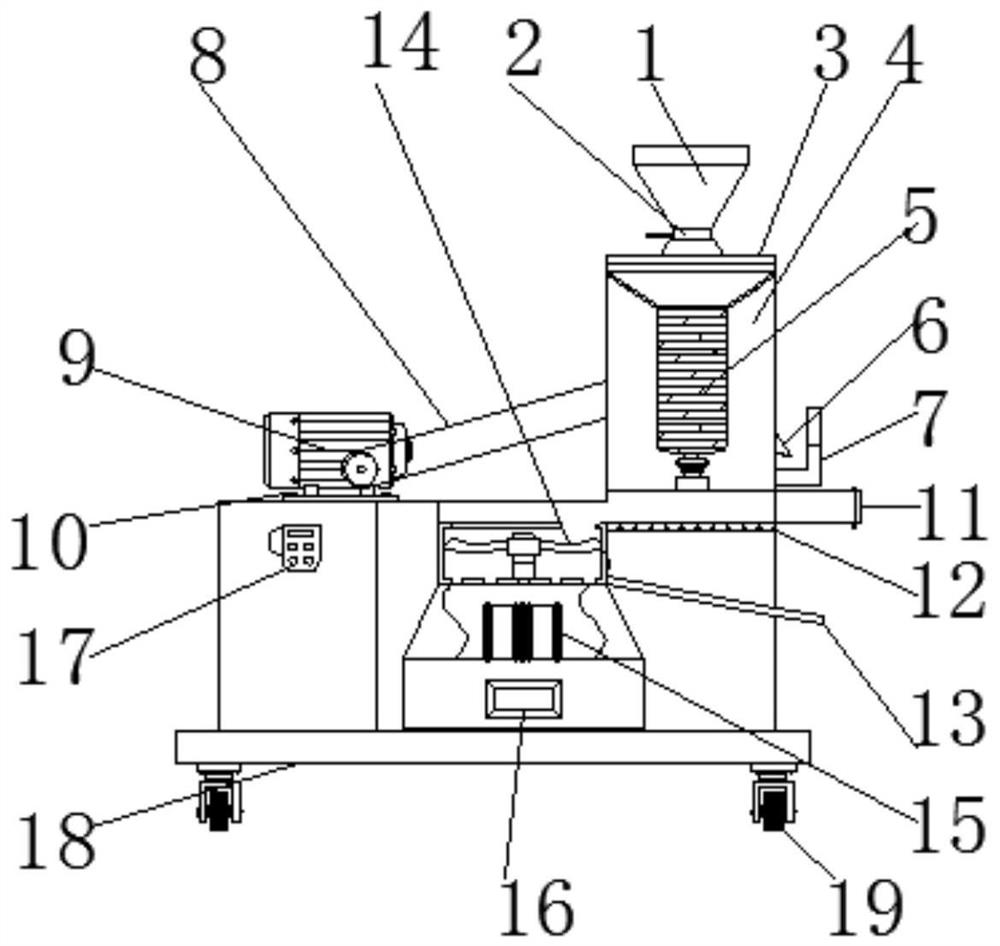

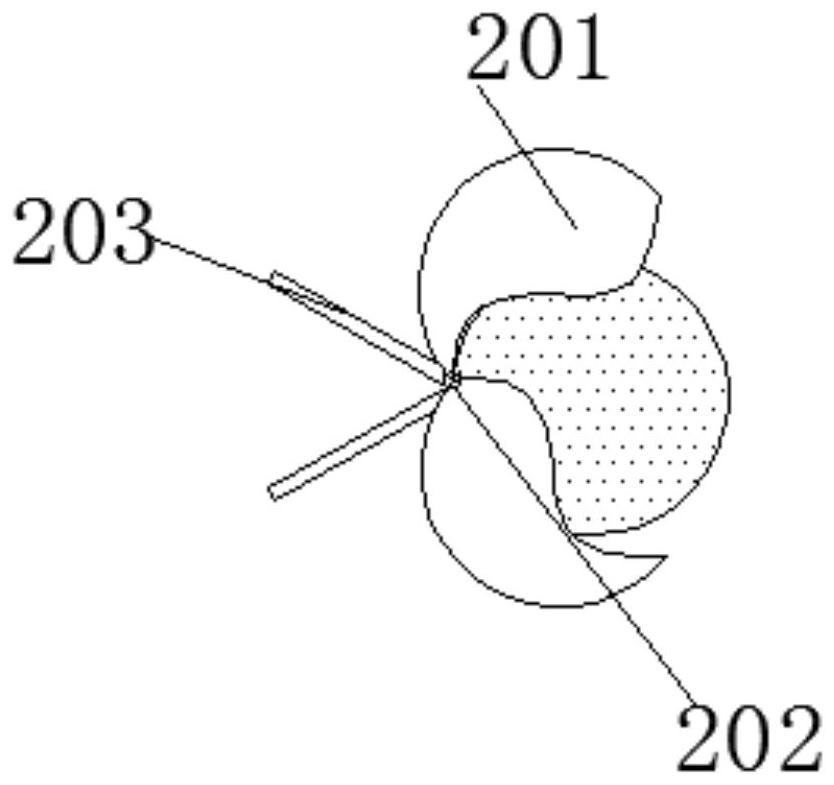

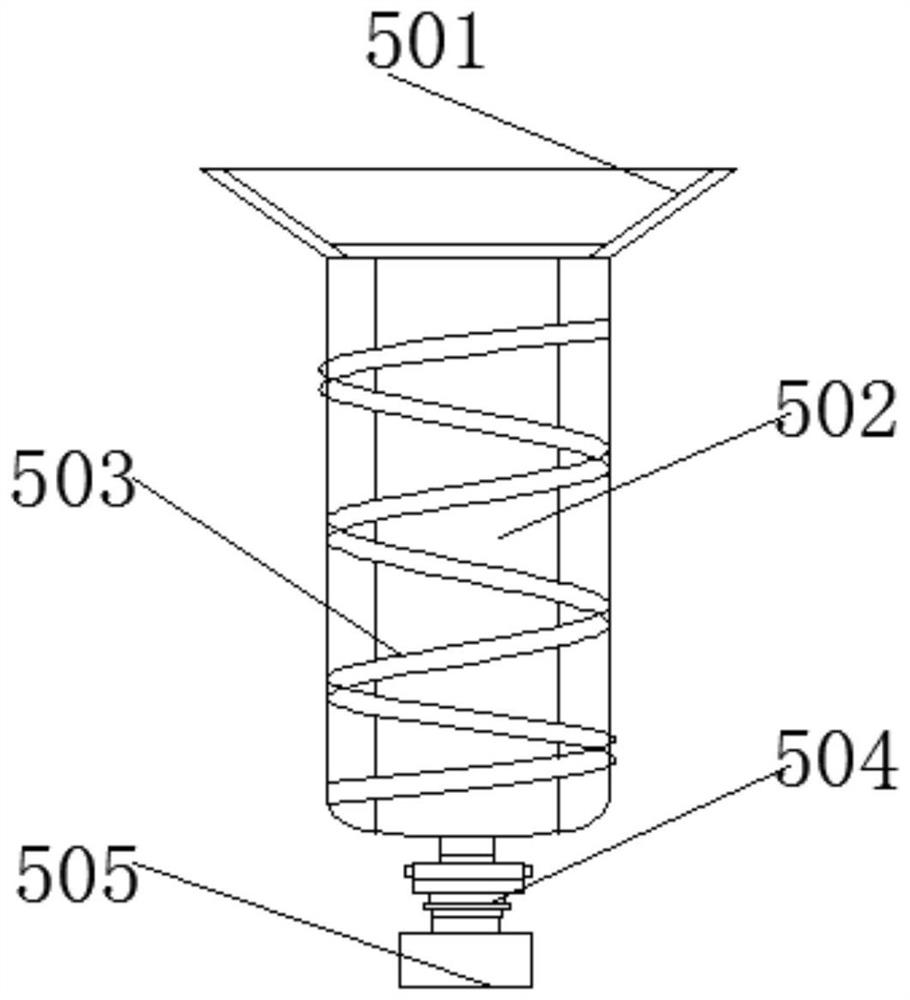

Dust removal device of parched rice powder making system

InactiveCN108325991APrevent compactionImprove dust removal effectCombination devicesDirt cleaningSlide plateCam

According to the scheme, the invention relates to the field of food processing, and discloses a dust removal device of a parched rice powder making system. The dust removal device comprises a water trough and a material collecting trough. The material collecting trough comprises a side part and a bottom part. Each second side wall of the side part comprises an outer wall and a sliding plate. Dustremoval units are arranged on the tops of the sliding plates. A top plate is connected between the two sliding plates and internally provided with a communication chamber. The communication chamber isinternally provided with a negative-pressure machine. An air spraying port is formed in the bottom of the communication chamber. Each outer wall is provided with a first opening, wherein a first rotation shaft is rotationally connected in the first opening and fixedly provided with a cam, rotation blades and a worm part. A second rotation shaft is rotationally connected in the water trough, a plurality of bailing troughs and a worm gear engaged with the worm part are fixed to the second rotation shaft, and the bailing troughs can abut against the material collecting trough in the rotation process. According to the scheme, the dust generated in the process of material collecting through the material collecting trough can be removed, parched rice powder making system pollution due to more generated dust is prevented, the materials are further cooled, and the output materials better meet the package requirement.

Owner:重庆市长寿区可又可食品有限公司

All-waterborne ink and preparation method thereof

ActiveCN110041750AImprove stabilityGood dispersionInksAir quality improvementPolyethylene vinyl acetateGlycidyl methacrylate

The invention belongs to the technical field of printing and particularly relates to all-waterborne ink and a preparation method thereof. A quaternary copolymerized water-soluble grinding resin solution is prepared from raw materials including hydroxyethyl methacrylate, glycidyl methacrylate, styrene and alginic acid, and a base material with stable performance is formed; the all-waterborne ink prepared from the base material, a connecting material, a water-soluble aid and water has good liquidity, high color concentration and good printability; a printed product is high in luster and good inleveling property, has comparable adhesion fastness and resistance with the solvent, and is free of harmful substance residues after drying. The printed product has adhesion resistance, mobility resistance, abrasion resistance and water resistance. The all-waterborne ink can be applied to surface printing of a shopping bag, a medical packaging bag, a transfer bag and a food bag made of plastic base materials such as BOPP (biaxially-oriented polypropylene), PET (polyethylene terephthalate), PE / PEVA (polyethylene / polyethylene vinyl acetate) and the like.

Owner:山东华诺日化有限公司

Solution for surgery and endoscope washing and preparation method thereof

InactiveCN102836171BIncrease osmotic pressureComply with injection requirementsSurgical drugsPharmaceutical delivery mechanismSodium acetrizoateSodium acetate

The invention relates to a solution for surgery and endoscope washing and a preparation method of the solution. Each 100mL of the solution contains 526mg of sodium chloride, 368mg of sodium acetate, 502mg of sodium gluconate, 37mg of potassium chloride and 30mg of magnesium chloride; and the pH value of the solution is 6.7 to 7.2 and the osmotic pressure is 280 to 300mOsmol / kg. The production process of the solution provided by the invention is managed according to the relevant quality standards of an injection, and the bacterial endotoxins and the insoluble particles completely accord with the requirements of the injection; and moreover, the polypropylene infusion bottles are served as an inner packing material, the contents and the packing material have good biocompatibility, so that the solution is convenient for clinical use and transportation and storage.

Owner:北京金康驰医药投资有限公司

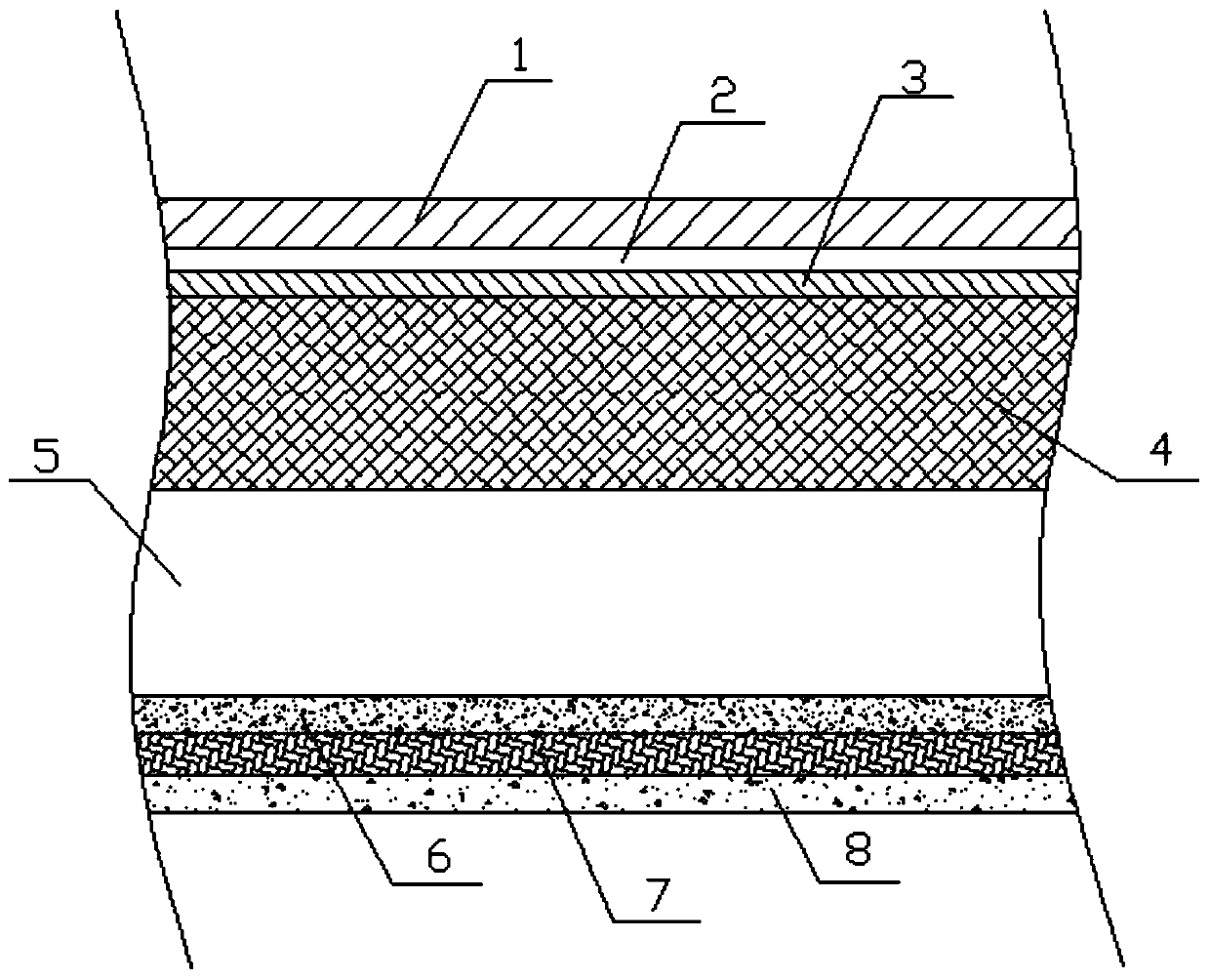

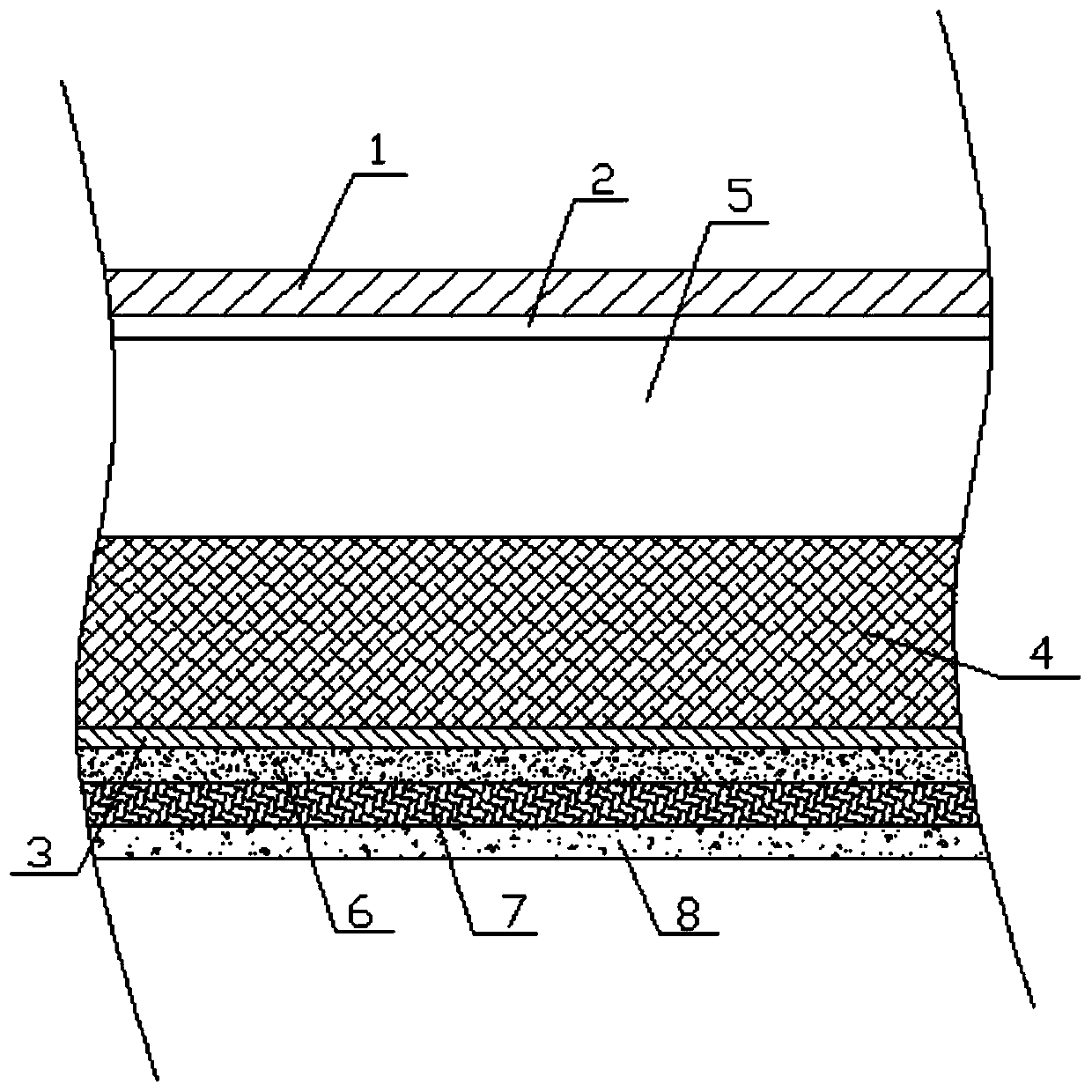

Protective floor mat for decoration

PendingCN110079236AImprove the protective effectPrevent slippingFlat articlesFilm/foil adhesive release linersWater basedAdhesive

The invention discloses a protective floor mat for decoration. The protective floor mat for decoration sequentially comprises the following structural layers from top to bottom: a casting polyethyleneCPE film as a first layer, a printing layer as a second layer, a laminating film PE as a third layer, polyethylene foamed cotton as a fourth layer, a polyethylene bubble film as a fifth layer, a blow-moulding polyethylene PE film as a sixth layer, a water-based non-setting adhesive as a seventh layer and a blow-moulding polyethylene release PE film as an eighth layer; or a casting polyethylene CPE film as a first layer, a printing layer as a second layer, a polyethylene bubble film as a third layer, polyethylene foamed cotton as a fourth layer, a laminating film PE as a fifth layer, a blow-moulding polyethylene PE film as a sixth layer, a water-based non-setting adhesive as a seventh layer and a blow-moulding polyethylene release PE film as an eighth layer. The protective floor mat for decoration is light in weight, good in protective effect, good in slip resistance and environment-friendly.

Owner:杭州新明包装有限公司

A kind of all-aqueous ink and preparation method thereof

ActiveCN110041750BImprove wettabilityPrevent flocculation and sedimentationInksAir quality improvementPolymer science(Hydroxyethyl)methacrylate

The invention belongs to the technical field of printing, and in particular relates to an all-aqueous ink and a preparation method thereof. The present invention adopts hydroxyethyl methacrylate, glycidyl methacrylate, styrene and alginic acid as raw materials to prepare a water-soluble grinding resin solution for quaternary copolymerization to form a base material with stable performance; The all-water-based ink prepared with solvent and water has good fluidity, high color concentration, and good printability; the printed matter has high gloss, good leveling, adhesion fastness and resistance comparable to solvent ink, and no harmful substances remain after drying . Prints are anti-blocking, anti-migration, abrasion-resistant and water-resistant. It can be used for surface printing of shopping bags, medical packaging, transfer bags and food bags printed on the surface of BOPP, PET, PE / PEVA and other plastic substrates.

Owner:山东华诺日化有限公司

Tray with limit structure

ActiveCN103241469BImprove compatibilityComply with packaging requirementsRigid containersDamagable goods packagingChip on filmEngineering

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

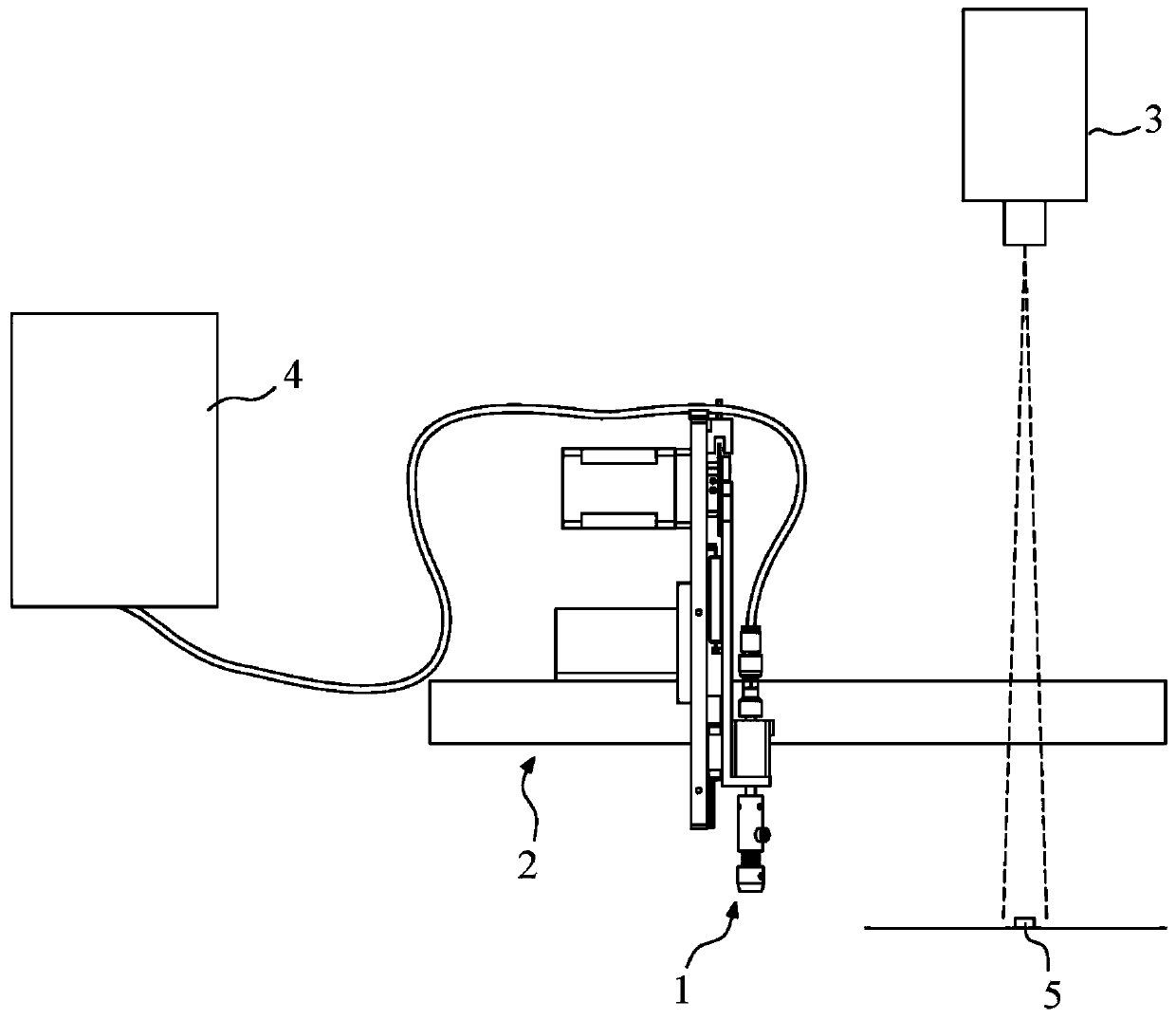

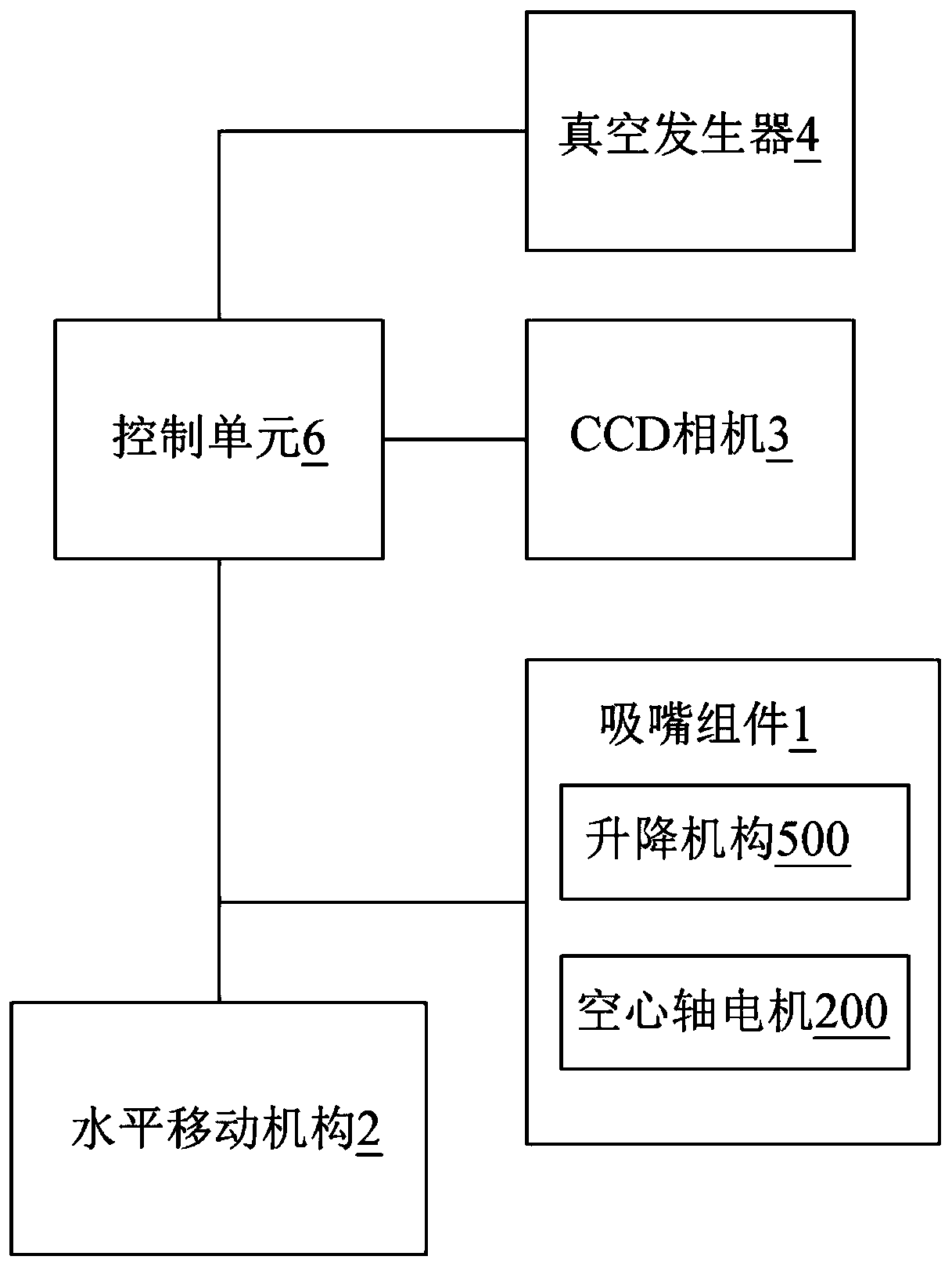

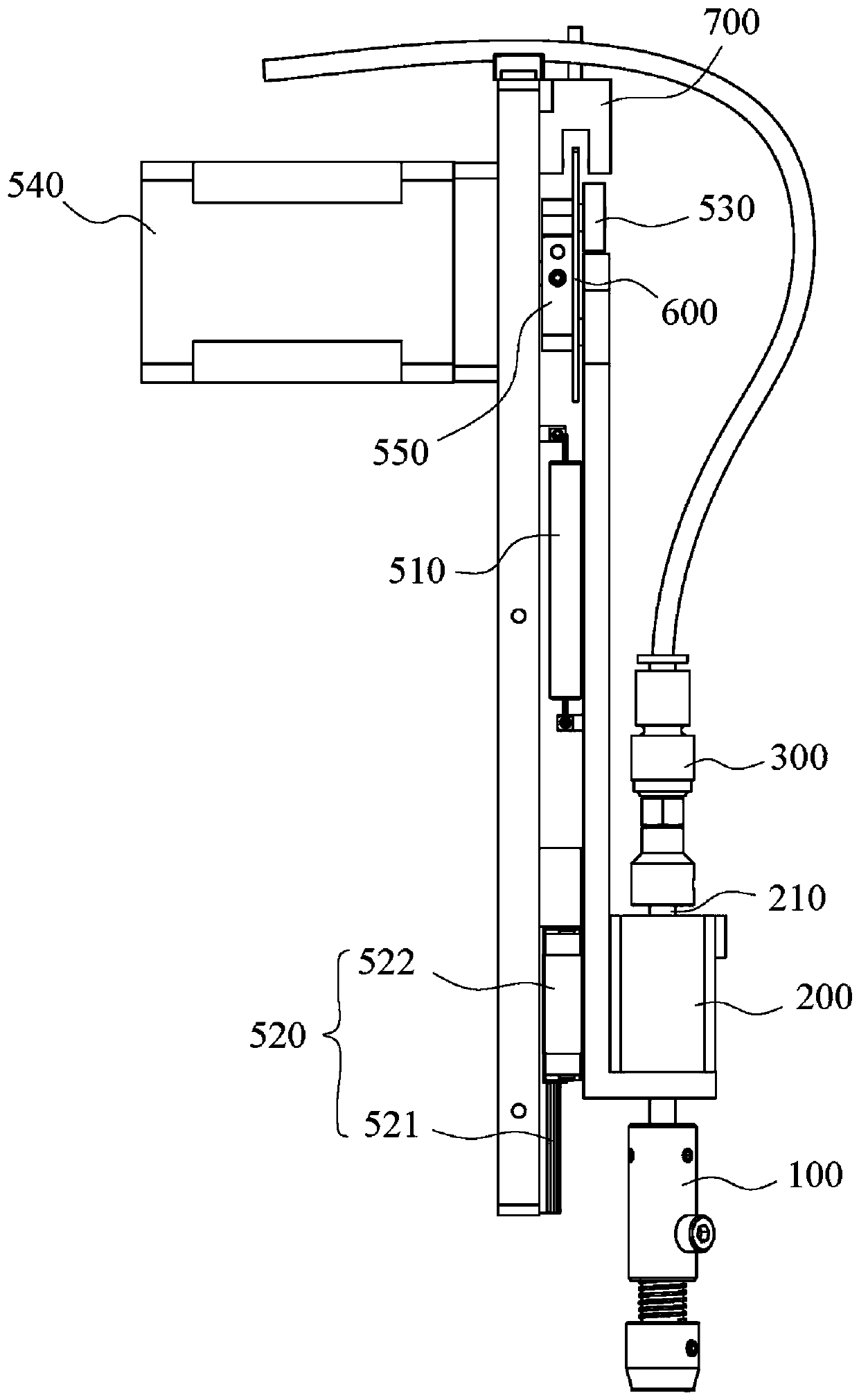

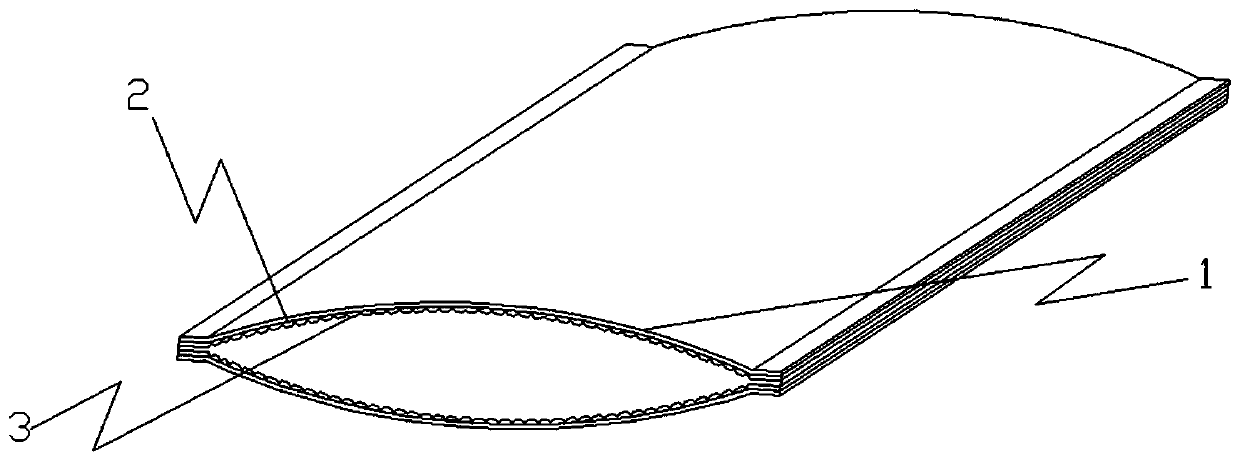

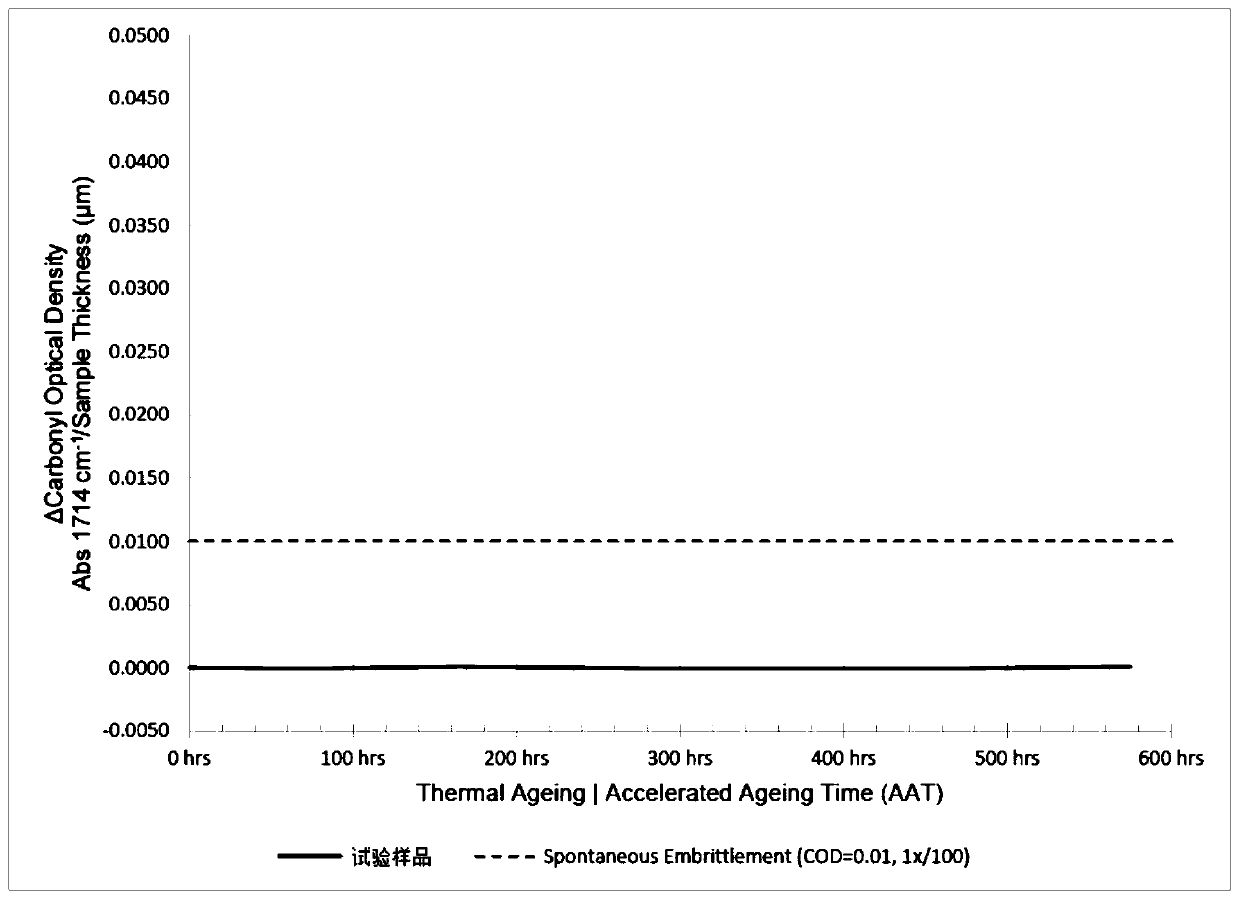

Novel transfer system and method for annular highlight product

The invention discloses a novel transfer system for an annular highlight product. The system comprises a suction nozzle assembly, a horizontal movement mechanism, a CCD camera and a vacuum generator,the suction nozzle assembly comprises one or more suction nozzles, a hollow shaft motor, a rotation joint and a mounting component capable of performing lifting motion, and each suction nozzle comprises a connection base, a suction head and a cushion block; the upper ends of the suction heads are connected with the connection bases, and the lower ends of the suction heads are provided with containing cavities; the cushion blocks are arranged in the containing cavities and made of elastic soft materials, the suction heads can reciprocate in the axial direction, and the hollow shaft motor is fixed to the mounting component; the lower end of a motor shaft of the hollow shaft motor is communicated with the connection bases, the upper end of the motor shaft is connected with the rotation joint,and the horizontal movement mechanism is used for driving the suction nozzle assembly to horizontally move; a lens of the CCD camera faces downwards and is used for shooting a product image, and thevacuum generator is connected with the rotation joint through an air guide pipe. The product transfer system can suck, rotate and transfer the annular highlight product. The invention further discloses a novel transfer method for the annular highlight product.

Owner:SUZHOU LINGYU ELECTRONICS TECH CO LTD

Vacuum sealing plastic bag capable of being naturally degraded

ActiveCN111169126AGuaranteed performanceHigh tensile strengthLamination ancillary operationsBio-packagingLow-density polyethyleneHigh density

The invention discloses a vacuum sealing plastic bag capable of being naturally degraded. The vacuum sealing plastic bag is formed by compounding a plurality of film layers, wherein at least one of the plurality of film layers is made of a degradation promoting material D2W, the plurality of film layers contain polyethylene, and the addition amount of the degradation promoting material is 5% of the addition amount of the polyethylene in percentage by mass. According to the invention, polyethylene materials including HDPE (high-density polyethylene), LDPE (low-density polyethylene), LLDPE (linear low-density polyethylene) and metallocene linear low-density polyethylene are compounded to form different film layers, so the comprehensive performance of the sealing plastic bag can meet the requirements of food packaging; the degradation promoting material is added, so oxidative degradation of the vacuum sealing plastic bag in the natural environment is promoted, and secondary pollution is avoided; and preparation process is simple, and the problems that plastic products are difficult to naturally degrade, low in environmental protection property, high in production cost and the like andhave influence on human health are solved on the whole.

Owner:DIFEN ELECTRIC APPLIANCE CO LTD

Tray with limiting structure

ActiveCN103241470BImprove compatibilityComply with packaging requirementsDamagable goods packagingEngineeringMechanical engineering

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Water-soluble water-resistant printing ink for plastic woven sack and preparation thereof

ActiveCN101302373BGood printabilityImprove securityInksOther printing apparatusSolubilityWater based

The invention relates to a water-solubility printing ink and a method for preparing the same, in particular to a printing ink for a water-solubility waterproof plastic woven bag and a method for preparing the same. The printing ink for the water-solubility waterproof plastic woven bag is prepared by the following compositions in percentage by weight: 30 to 55 percent of crylic acid added rosin resin, 8 to 12 percent of nontoxic pigment, 12 to 20 percent of water, 8 to 12 percent of ammonia, 10 to 15 percent of pure acrylic emulsion, 3 to 6 percent of water-based wax, 0.1 to 1 percent of defoaming agent and 0.3 to 1 percent of flatting agent, which are in mass percentage. The printing ink solves the disadvantages of a solvent-type plastic woven bag after being printed by the printing ink has the influence of odor of the residual solvent; and a water-based woven bag after being printed has the poor water resistance, etc. The product can be widely used in the packaging printing of the plastic woven bag of grain, vegetable, tobacco, food, solid beverage and other industries, in particular to farm and sideline products, food and other aspects which relate to the packaging of hydrous products. The printed product can ensure safety and nontoxicity, can not produce the harm to human health and is a green and environment-friendly product.

Owner:浙江永在油墨有限公司

Aluminum-free anti-counterfeiting lining paper for cigarettes and production method thereof

InactiveCN102587206BLow pricePlay an anti-counterfeiting roleCoatings with pigmentsSpecial paperPolyvinyl alcoholAdhesive

The invention provides an aluminum-free anti-counterfeiting lining paper for cigarettes and a production method thereof. The lining paper is composed of an anti-counterfeiting paper layer, a coating layer and an aqueous printing oil layer. The technical indexes are as follows: the fixed quantify is 60+ / -3 g / m<2>; the thickness is 0.07+ / -0.005 mm; the flatness is more than or equal to 80 S; the tensile strength is more than or equal to 1.8 kN / m; the whiteness is more than or equal to 80%; the water content is 4-6%; and the air permeability is less than or equal to 0.01 micron / Pa.s. The production method comprises the following steps of: firstly preparing a coating; and then, coating the prepared coating on front and back sides of anti-counterfeiting paper on a coating machine, so as to prepare a product. According to the production method, the anti-counterfeiting paper is used as basic paper and an anti-counterfeiting function is organically combined with the lining paper for the cigarettes, thereby achieving the anti-counterfeiting effect and greatly reducing the cost. The formula of the coating used in the preparation method is unique and a main paint part is papermaking porcelain clay which is widely applied to the papermaking industry and is low in price and an adhesive is polyvinyl alcohol and has no extraneous odor or toxicity; in the production process, no organic solvent is used and no pollutant is generated, thereby protecting environment. Non-ferrous metal such as aluminum foils, aluminum powder and copper powder, is not used, so that the product cost is low, the energy consumption is low, and ideals of energy saving and environmental protection and low-carbon lifestyle are realized.

Owner:杜荣安 +2

A peeling device for grain production

ActiveCN110586226BHigh peeling rateAvoid breakingGrain huskingGrain polishingAgricultural engineeringElectric machinery

The invention discloses a peeling device for grain production, a peeling device for grain production, comprising a grain inlet, a box cover, a peeling device, a guide rod, a motor, a drying plate, a water guide, a drying device, and a grain outlet , a controller, a base, an air dryer, a buckle and a card slot, the lower surface of the grain inlet is provided with an adjusting opening device, the box cover is installed under the adjusting opening device, and the lower surface of the box cover is connected with a box body, The peeling device is installed inside the box, the outer surface of the box is fixedly connected with a grain skin outlet, the lower end of the grain skin outlet is provided with a groove, the guide rod is arranged on the outer surface of the box, and the motor is fixed It is connected to the outer surface of the guide rod, and the bottom end of the motor is inserted and connected with bolts. The peeling device for grain production is equipped with a centrifugal peeling device, and the centrifugal device is used to separate the grain from the skin. Compared with the traditional grain peeling device, the effect is better, the grain peeling rate is improved, and the grain is avoided. Broken condition.

Owner:安徽雪莲面粉有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com