Tray with limit structure

A limit structure and pallet technology, applied in rigid containers, fragile goods packaging, containers, etc., can solve the problems of COF2 pulling damage, OpenCellB6 cannot be used, increase the cost of production links, etc., and achieve the effect of expanding compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

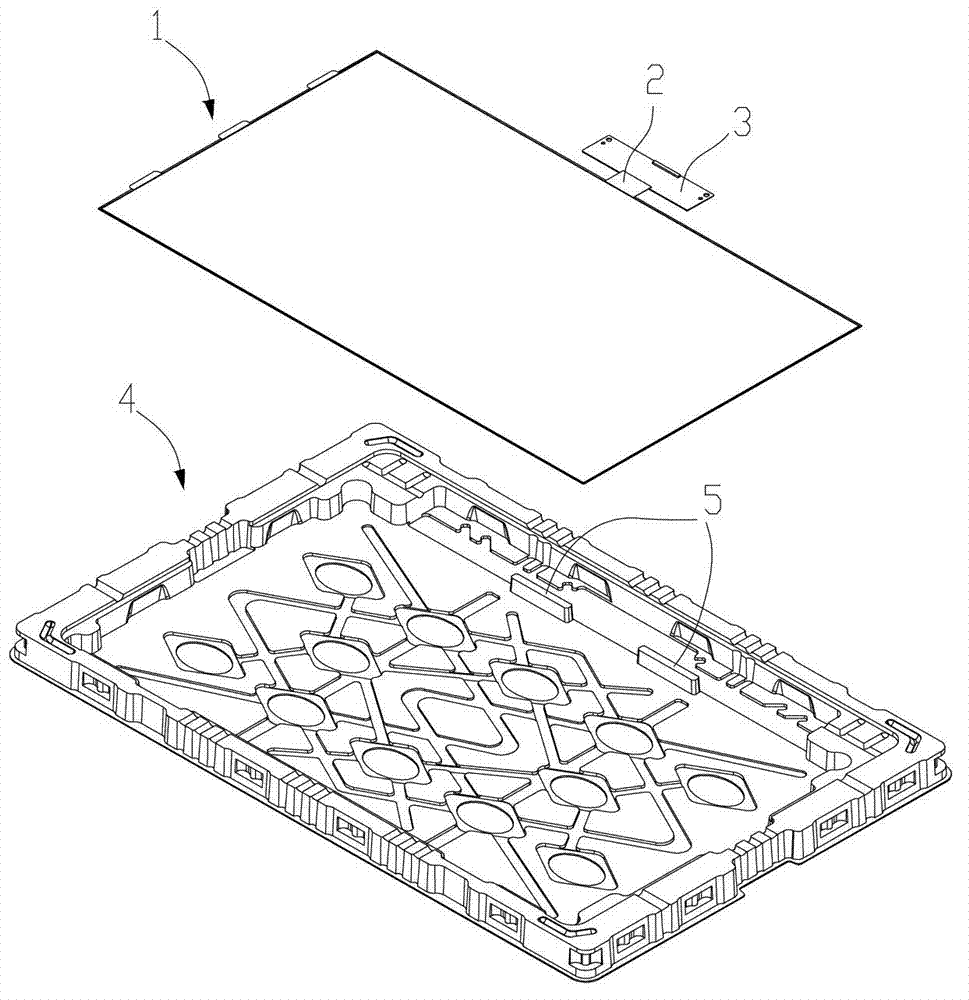

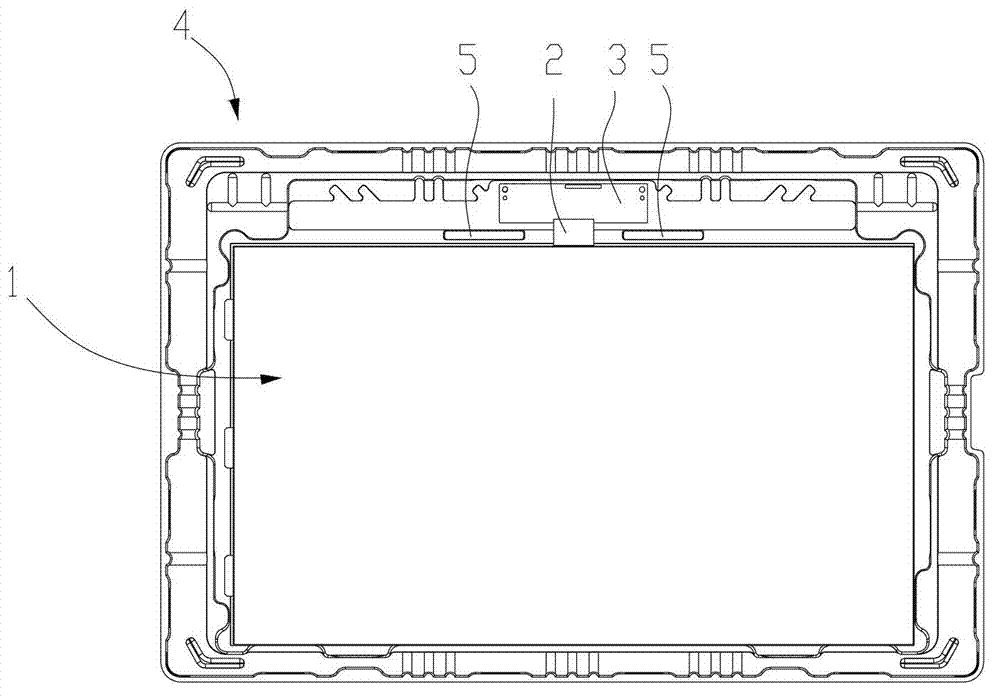

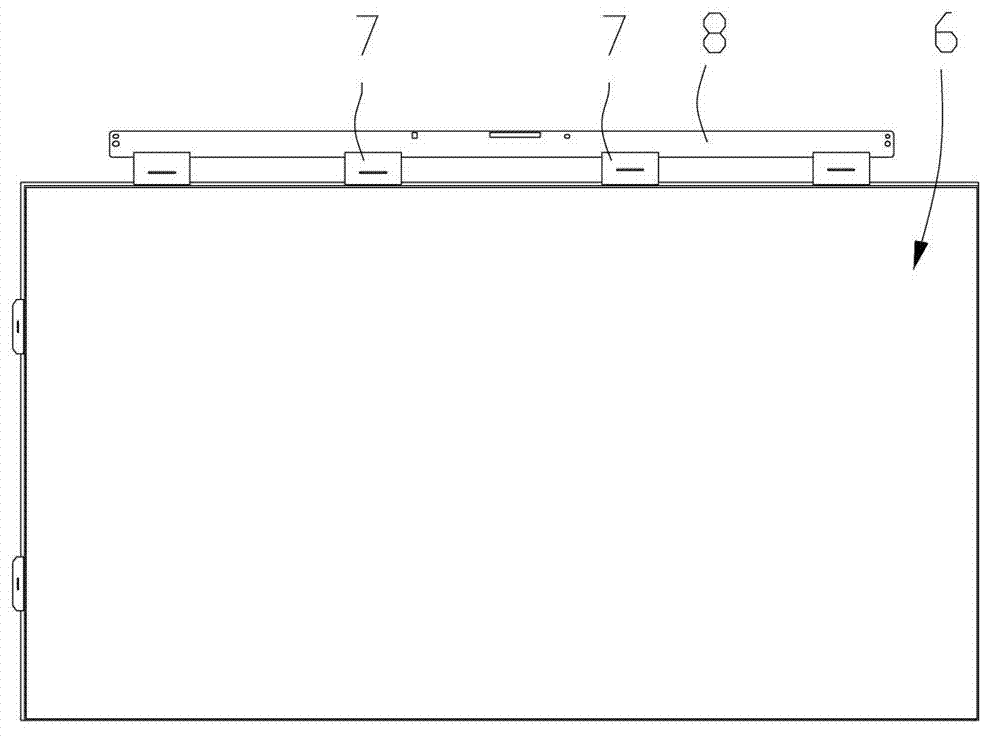

[0022] Such as Figure 4 , Figure 5 As shown, the tray for placing the Open Cell of the LCD screen includes a tray body 10, the tray body 10 is provided with a groove 11 for placing the Open Cell, the Open CellA20 is placed in the groove 11, and the Open Cell A20 is connected by a COF21 Liquid crystal box 22, PCB board 23 form. In addition, it also includes a buckle 30, see also Image 6 , The buckle 30 is composed of two mutually hinged components, namely a fixing component 31 and a buckling component 32 . The fixing member 31 includes a fixing part 311 and a receiving part 312, which are integrally formed in a stepped shape, and 32 buckle members are hinged at the steps, and when the buckle member 32 rotates toward the receiving part 312, it finally fits on the receiving part 312. On the surface, this can prevent the buckle member 32 from directly pressing on the PCB board 23 , and also keep the installation effect of the two buckle parts 30 assembled on both sides of th...

Embodiment 2

[0025] This embodiment differs from Embodiment 1 in the structure of the buckle, and other similar structures will not be repeated here. Such as Figure 7 As shown, the buckle 50 is hinged by a fixing member 51 and a buckling member 52 . This structure makes it possible for the buckle member 52 to be pressed against the PCB without being restricted by the receiving portion as in Embodiment 1 when it rotates downward. Therefore, the length of the buckle part 53 in the buckle member can be designed to be long enough, so that when the end of the buckle part 53 is inserted into the bottom surface of the tray, it can avoid being pressed against the PCB. Similarly, a layer of antistatic buffer gasket 41 is provided on the outer surface of the buckle part 53 , and an adhesive is provided on the side surface 54 of the fixing member 51 to adhere to the inner wall of the tray body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com