Polyester/low-density polyethylene composite film for packaging and preparation method of polyester/low-density polyethylene composite film

A technology for low-density polyethylene and packaging, applied in chemical instruments and methods, lamination devices, synthetic resin layered products, etc., can solve the problems of huge cost, environmental pollution, etc., and achieve environmental degradation, strong adhesion, The effect of scientific production technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

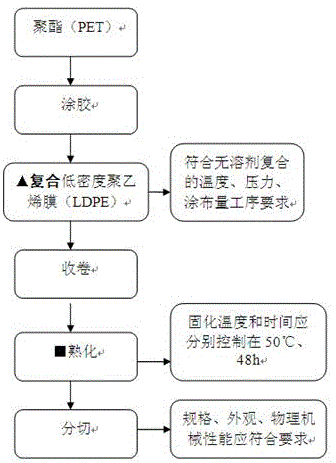

Method used

Image

Examples

Embodiment 1

[0029] Take 18000kg of polyethylene terephthalate film with a thickness of 0.2mm, and keep the pressure at 0.3Mpa; first, apply 45kg of glue A, keep the temperature of the glue at 30°C, and the speed of the coating roller at 250 rpm. The temperature is 50°C, spread evenly; after the A glue is completely cured, start to coat 45kg of B glue, the temperature of B glue is kept at 40, the speed of the coating roller is 250 rpm, and the total coating amount of the mixed glue is 1.5g / m2. Then it is laminated with a low-density polyethylene film weighing 1910 kg and having a thickness of 0.05 mm, rolled up, cured at 40°C for 36 hours, cut, quality inspected, weighed at 19950 kg, and put into storage.

Embodiment 2

[0031] Take 18,000kg of polyethylene terephthalate film with a thickness of 0.25mm, and keep the pressure at 0.4 Mpa; first, coat 45kg of glue A, keep the temperature of the glue at 35°C, and the speed of the coating roller at 300 rpm. The temperature is 50°C, spread evenly; after the A glue is completely cured, start to coat 40kg of B glue, the temperature of B glue is kept at 45°C, the speed of the coating roller is 300 rpm, and the total coating amount of the mixed glue is 2g / m2. Then it is laminated with a low-density polyethylene film weighing 1900 kg and having a thickness of 0.05 mm, rolled, aged, aged at 50°C for 48 hours, cut, quality inspected, weighed 19980 kg, and put into storage.

Embodiment 3

[0033] Take 17,500kg of polyethylene terephthalate film with a thickness of 0.3mm, and keep the pressure at 0.5 Mpa; first, apply 45kg of glue A, keep the temperature of the glue at 40°C, and the speed of the coating roller at 350 rpm. The temperature is 50°C, spread evenly; after the A glue is completely cured, start to coat 36kg of B glue, the temperature of B glue is kept at 50°C, the speed of the coating roller is 350 rpm, and the total coating amount of the mixed glue is 2g / m2. Then it is laminated with a low-density polyethylene film weighing 2450kg and having a thickness of 0.05mm, rolled, aged, aged at 50°C for 48 hours, cut, quality inspected, weighed 20030kg, and put into storage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com