Protective floor mat for decoration

A floor mat and polyethylene technology, applied in the direction of film/sheet release liner, film/sheet adhesive, application, etc., can solve the problems of non-slip, poor protection effect, not environmental protection, etc., to prevent personnel Slipping, avoiding secondary pollution, and excellent protective performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

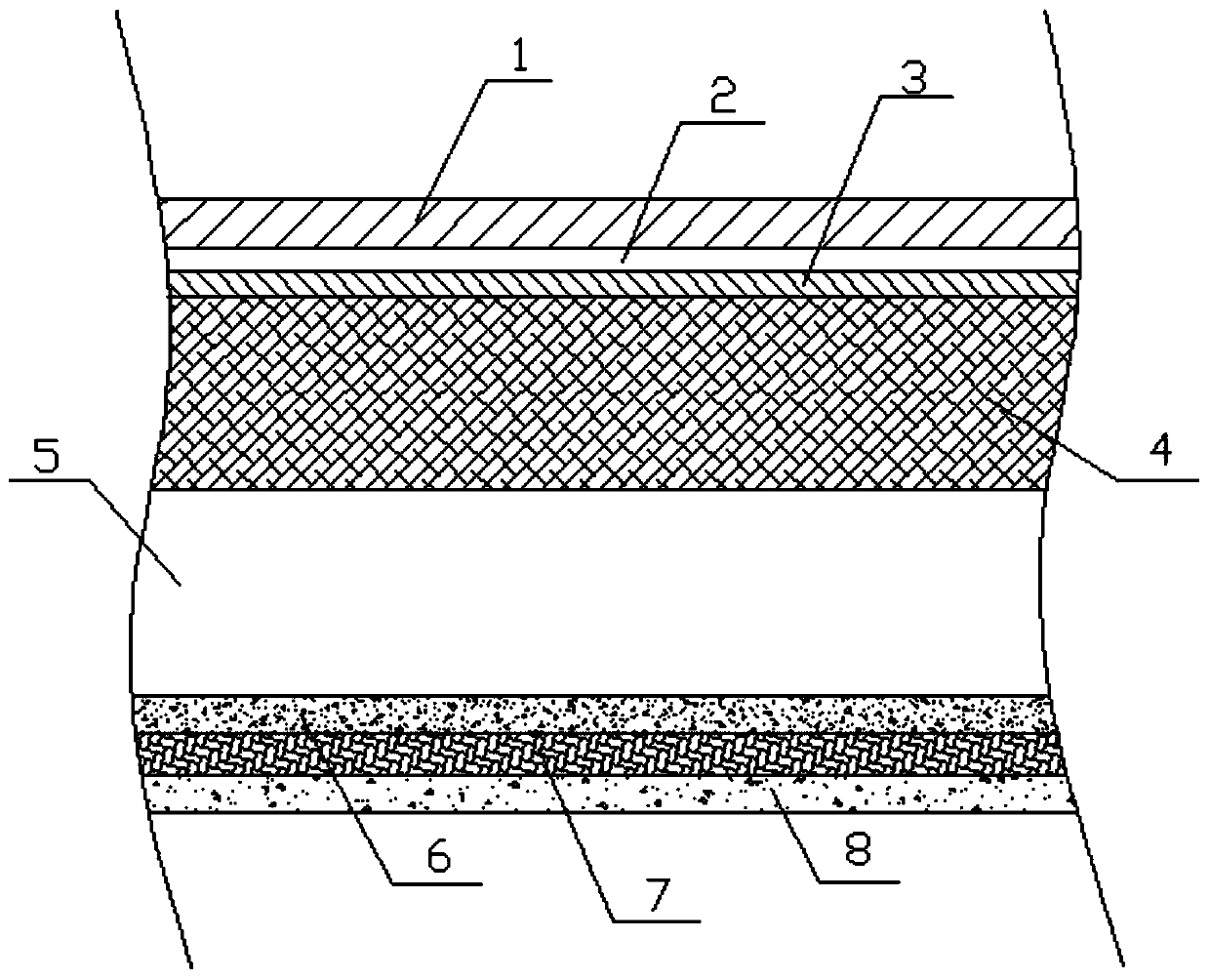

[0060] Such as figure 1 The decoration protective floor mat shown in the figure includes the following structural layers in order from top to bottom:

[0061] The first layer: cast polyethylene CPE film 1

[0062] The second layer: printing layer 2

[0063] The third layer: coated PE3

[0064] The fourth layer: polyethylene foam cotton 4

[0065] The fifth layer: polyethylene bubble film 5

[0066] The sixth layer: blown polyethylene PE film 6

[0067] The seventh layer: water-based self-adhesive 7

[0068] The eighth layer: blow molding polyethylene release type PE film 8;

[0069] The polyethylene bubble film is a polyethylene bubble film with single-layer bubbles, and the bubbles are cylindrical bubbles.

Embodiment 2

[0071] The difference between this embodiment and Embodiment 1 is that the polyethylene air bubble film is a double-layer air bubble film.

Embodiment 3

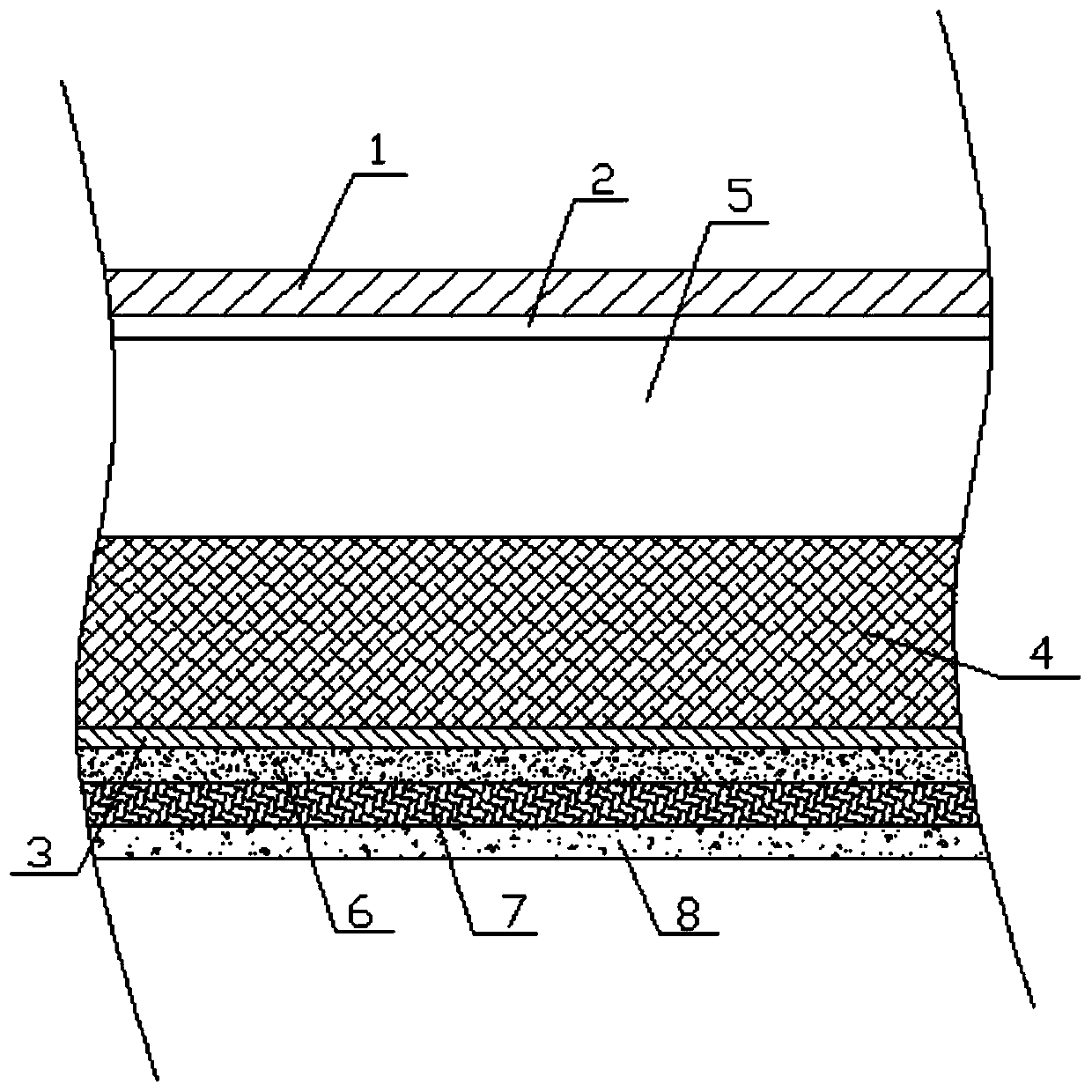

[0073] Such as figure 2 The decoration protective floor mat shown in the figure includes the following structural layers in order from top to bottom:

[0074] The first layer: cast polyethylene CPE film 1

[0075] The second layer: printing layer 2

[0076] The third layer: polyethylene bubble film 5

[0077] The fourth layer: polyethylene foam cotton 4

[0078] The fifth layer: coated PE3

[0079] The sixth layer: blown polyethylene PE film 6

[0080] The seventh layer: water-based self-adhesive 7

[0081] The eighth layer: blow molding polyethylene release type PE film 8;

[0082] The polyethylene bubble film is a polyethylene bubble film with single-layer bubbles, and the bubbles are cylindrical bubbles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com