Novel transfer system and method for annular highlight product

A transfer system and product technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of difficult suction and transfer, small adsorption area, etc., and achieve the effect of preventing crushing and bonding tightly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

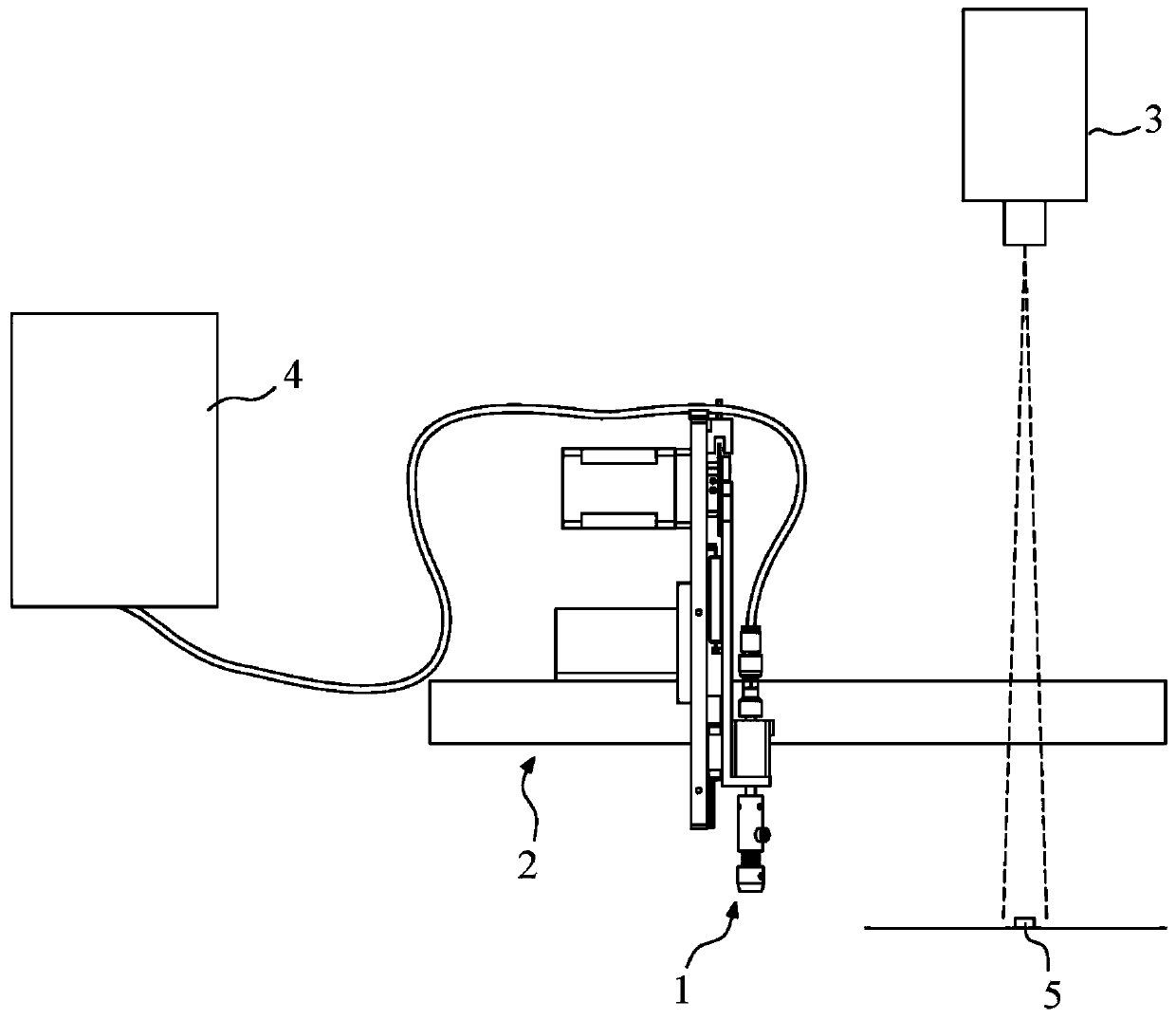

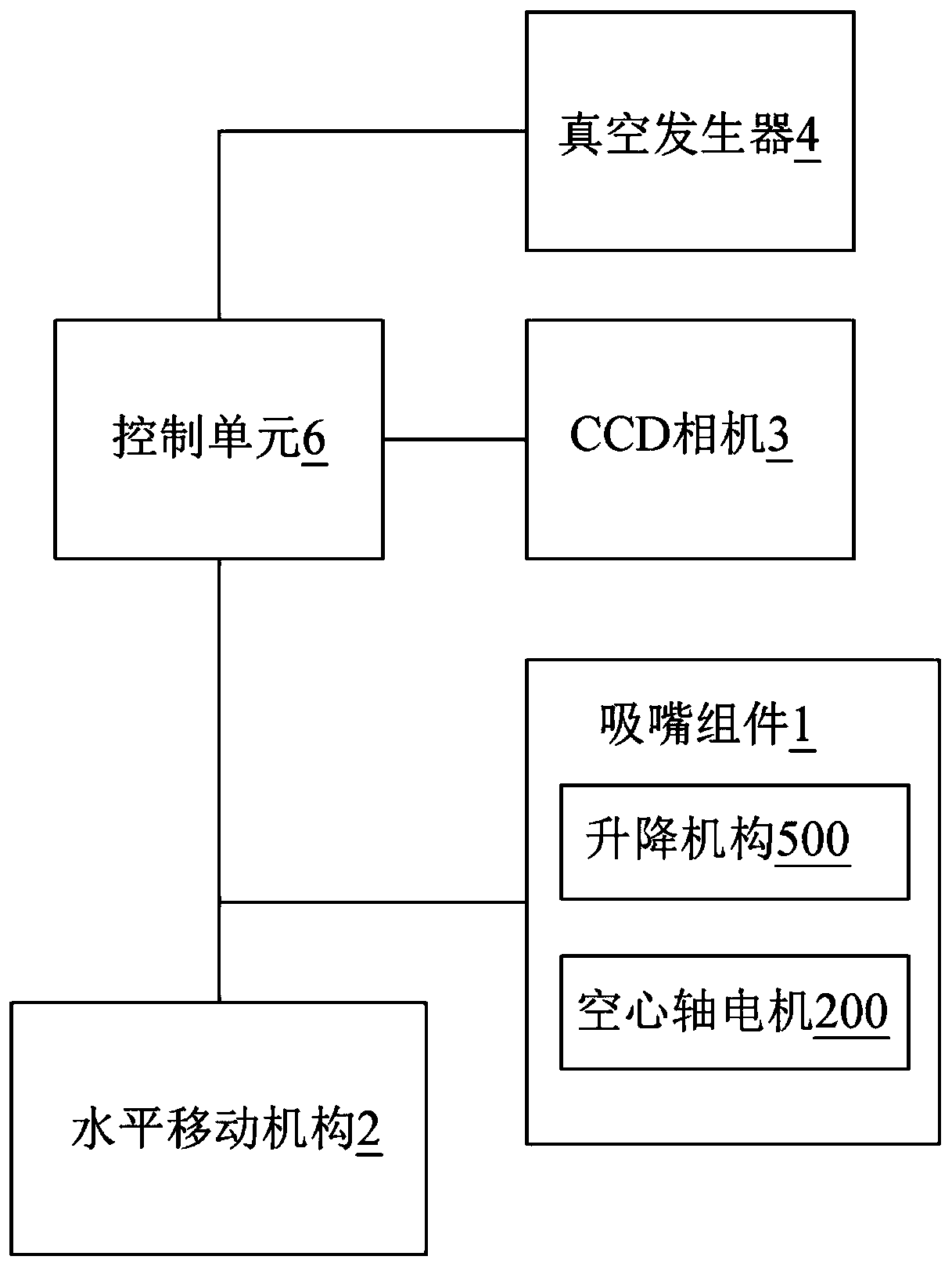

[0037] According to one aspect of the present invention, a novel annular highlight product transfer system is provided. Please refer to

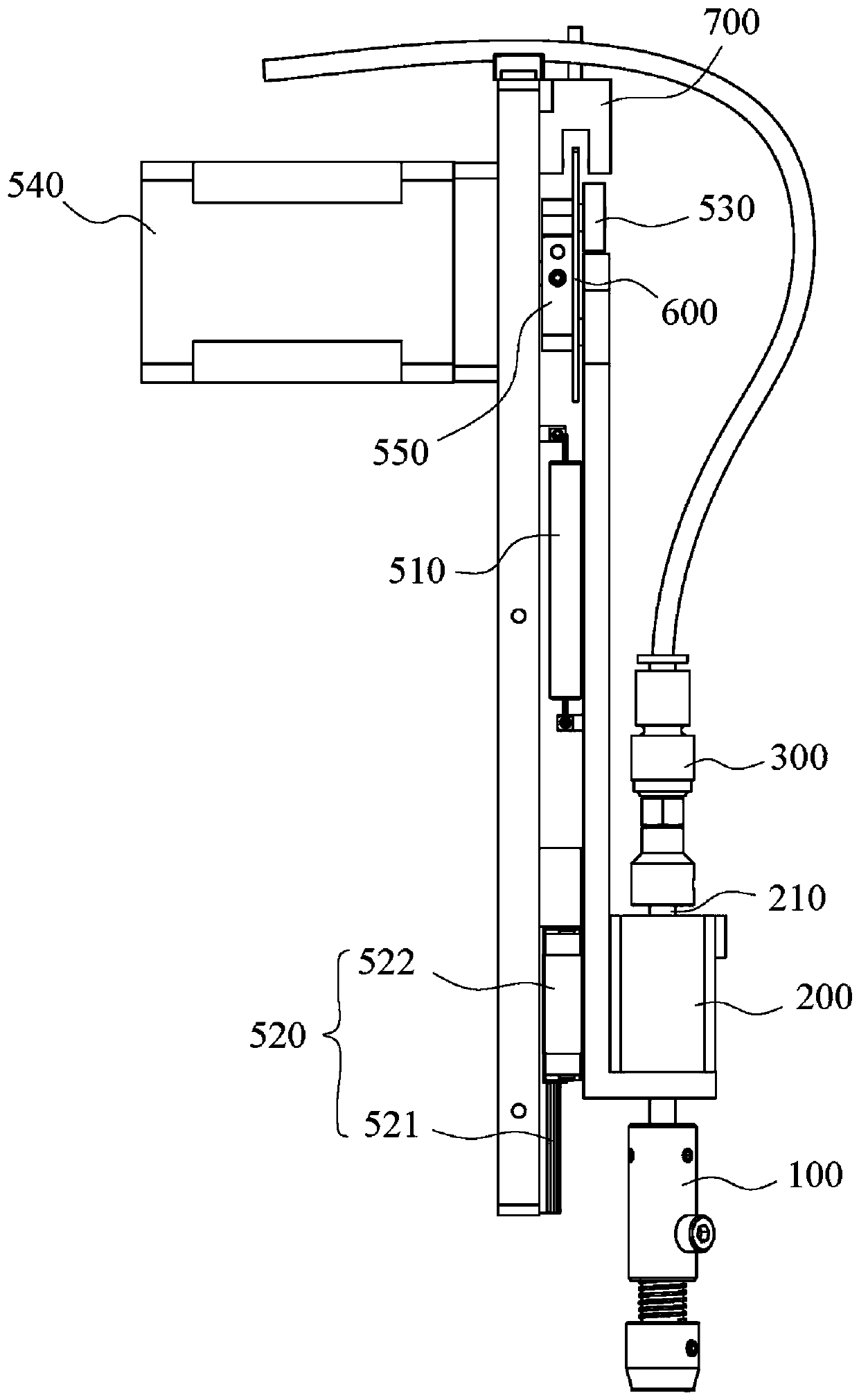

[0038] figure 1 , the transfer system includes a suction nozzle assembly 1 , a horizontal movement mechanism 2 , a CCD camera 3 and a vacuum generator 4 . Please combine image 3 and Figure 4 The suction nozzle assembly 1 includes at least one suction nozzle 100 , a hollow shaft motor 200 , a rotary joint 300 and a mounting part 400 capable of lifting and lowering. The hollow shaft motor 200 is fixed on the mounting part 400, and its motor shaft 210 and the suction nozzle 100 are arranged vertically. 4 are connected with air duct. The horizontal movement mechanism 2 includes two linear modules arranged orthogonally, wherein the suction nozzle assembly 1 is connected to one of the linear modules, so that the suction n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com