All-waterborne ink and preparation method thereof

An all-water-based ink technology, applied in the field of printing, can solve the problems of poor compatibility of color paste system and rheological property adjustment system, weak preparation technology of ink precursor pigment color paste, poor stability of water-based ink, etc., and achieve excellent tinting strength and Adhesion fastness, optimized grinding process, good wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0034] Preparation of water-soluble grinding resin liquid:

[0035]Add 5.0L solvent acetone to a 10.0L reactor, add 40g hydroxyethyl methacrylate (HEMA), 60g glycidyl methacrylate (GMA), 80g alginic acid (A) and 200g styrene (S) under nitrogen atmosphere , 5g dibenzoyl peroxide (BPO) as initiator, be warming up to reflux stirring and carry out free radical polymerization 18-24h;

[0036] Then remove the acetone under reduced pressure, evaporate the acetone to dryness, slowly add deionized water to adjust the non-volatile components to 35wt%, and finally use 0.2mol / L sodium hydroxide aqueous solution to adjust the acid value of the system resin solution to 168 to obtain a quaternary copolymer water-soluble grinding resin liquid.

Embodiment 1

[0038] The water-soluble grinding resin liquid prepared in manufacturing example 1 is used as grinding resin to prepare base material, and the method is as follows:

[0039] Add 240g water, 160g water-soluble grinding resin liquid, 500g pigment (roller carbon black, particle size 1.1-1.2 microns), 50g dispersant (TEGO Dispers 760W), 3.5g defoamer (TEGO Foamex 810) to the high-speed After the stirrer stirred for about 30 minutes, then add 45g thinning resin emulsion (the HC-8102B type ink resin produced by Foshan Sanshui Haocheng Synthetic Resin Co., Ltd.) and disperse with a high-speed grinder for 1-2 hours to obtain the base material; High-speed grinder dispersion refers to grinding at room temperature (20-30°C) with a grinding speed of 2000-2200 rpm; the grinding medium used in the high-speed grinder is zirconia beads with a particle size of 0.4-0.6mm. The material ratio is 4:1.

Embodiment 2

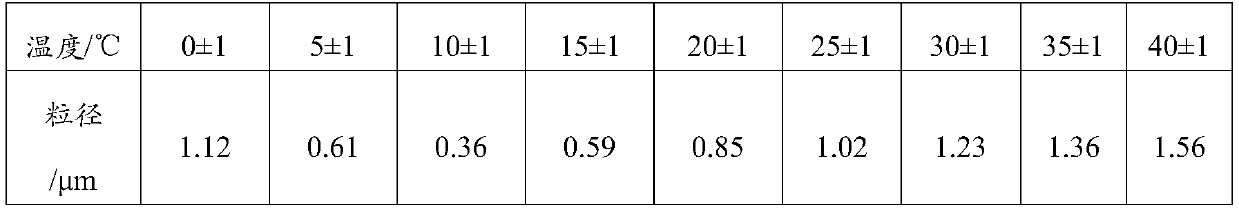

[0052] In the preparation process of the base material, the present invention surprisingly finds that the base material prepared in winter has good stability, and the particle size is basically distributed between 0.3-0.6 μm; while the base material prepared in summer has poor stability, and the particle size is basically Distributed between 1.2-1.5 μ m; so the present invention has carried out systematic optimization to the grinding temperature of base material, method is as follows:

[0053] Add 240g water, 160g water-soluble grinding resin liquid, 500g pigment (roller carbon black, particle size 1.1-1.2 microns), 50g dispersant (TEGO Dispers 760W), 3.5g defoamer (TEGO Foamex 810) to the high-speed After the stirrer stirred for about 30 minutes, then add 45g thinning resin emulsion (the HC-8102B type ink resin produced by Foshan Sanshui Haocheng Synthetic Resin Co., Ltd.) and disperse with a high-speed grinder for 1-2 hours to obtain the base material; High-speed grinder dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com