Method for preparing tungsten molybdenum copper composite material by microwave sintering

A composite material and microwave sintering technology, which is applied in the field of microwave sintering tungsten-molybdenum-copper composite materials, can solve the problems of long sintering time, high sintering temperature, complicated process, etc., and achieves short sintering time, low sintering temperature, and shortened time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~21

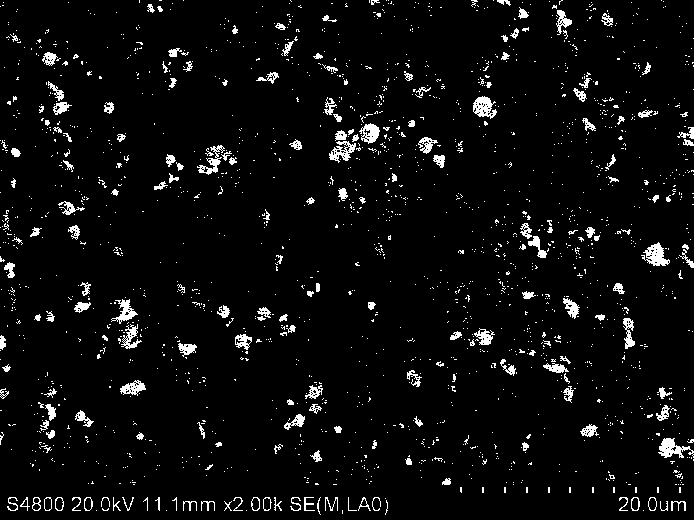

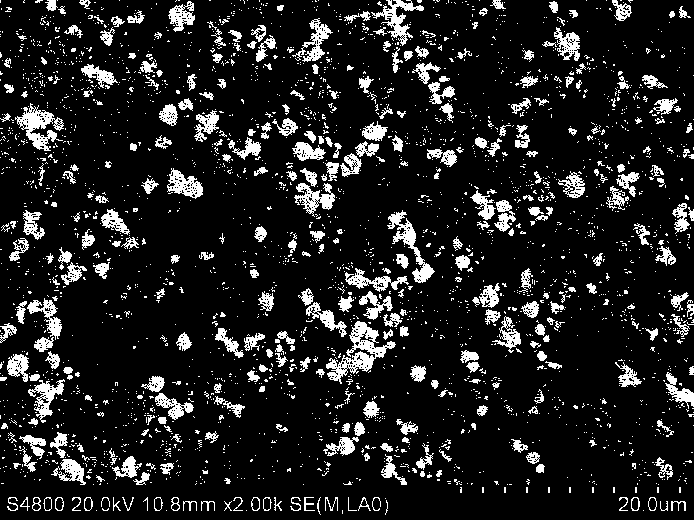

[0028] 1. Put copper powder with a particle size of 5~75μm, tungsten powder and molybdenum powder with a particle size of 2~3μm into the high-energy planetary ball mill for ball milling according to the mass ratio listed in the table, and add a little alcohol into the ball mill tank at the same time To prevent the powder from being oxidized during the ball milling process.

[0029]2. Put the tungsten-molybdenum-copper powder mixed by the ball mill into the mold and press it into a green body with a cylindrical structure, and the relative density of the green body is kept at 68%~78%.

[0030] 3. Place the green body in the microwave sintering furnace, heat the green body to 200°C and keep it warm for 1-5 minutes, then raise the temperature to 700-1000°C at a heating rate of 25-50°C / min and hold it for 5-20 minutes, then turn off the power Furnace cooling completes sintering to obtain W-Mo-Cu alloy.

[0031] 4. During the sintering process, the shape of the green body remains i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com