Method for recycling rhodium from rhodium octanoate mother liquor

A technology of rhodium octanoate and mother liquor, which is applied in the field of recovering rhodium from rhodium octanoate mother liquor, can solve the problems of complex purification process, large amount of rhodium ash, and low rhodium yield, and achieve simple process flow, low pollution and high recovery rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

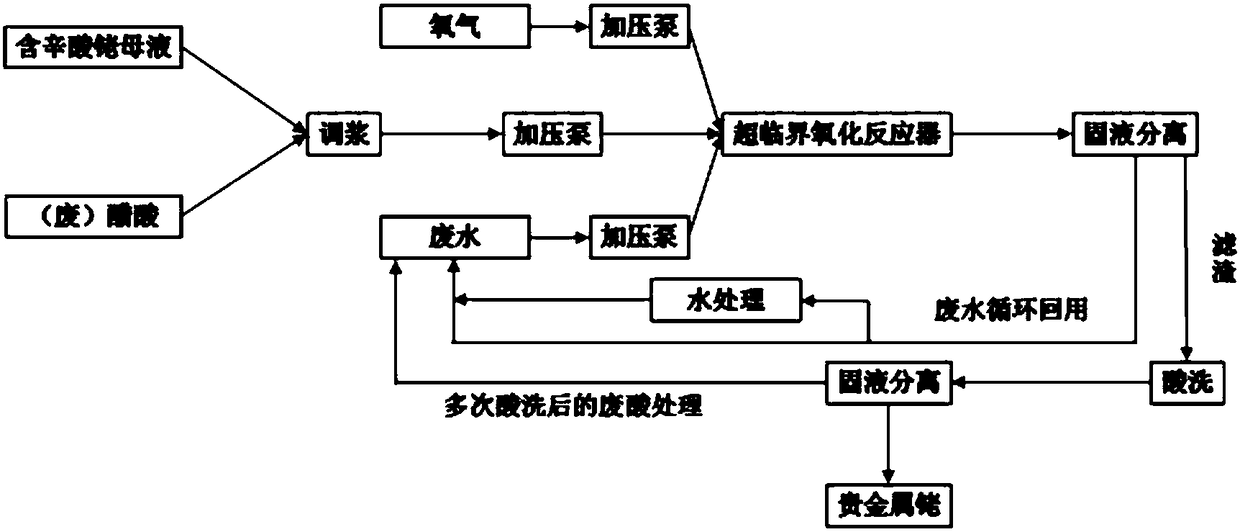

[0036] The method for reclaiming rhodium from octanoic acid rhodium mother liquor, comprises the steps:

[0037] (1) mix octanoic acid rhodium mother liquor and acetic acid with mass ratio 1:1 and carry out pulping process, obtain slurry;

[0038] (2) After the slurry and wastewater are mixed, the flow ratio of the slurry and wastewater into the three channels is determined by the mass and calorific value, so that the calorific value of the slurry and wastewater is mixed at 4-6MJ / kg, and oxygen is introduced as an oxidant , carry out supercritical oxidation treatment, the material from the supercritical oxidation reactor is decompressed in multiple stages, and the gas-liquid separation is obtained to obtain a gas phase system and a non-gas phase system, and the non-gas phase system uses a ceramic ultrafiltration membrane for solid-liquid separation treatment to obtain the first solid phase, wherein the wastewater obtained from solid-liquid separation is returned to supercritic...

Embodiment 2

[0042] The method for reclaiming rhodium from octanoic acid rhodium mother liquor, comprises the steps:

[0043] (1) mix octanoic acid rhodium mother liquor and acetic acid with mass ratio 1:3 and carry out pulping process, obtain slurry;

[0044] (2) After the slurry and wastewater are mixed, the flow ratio of the slurry and wastewater into the three channels is determined by the mass and calorific value, so that the calorific value of the slurry and wastewater is mixed at 4-6MJ / kg, and oxygen is introduced as an oxidant , carry out supercritical oxidation treatment, after the material from the supercritical oxidation reactor undergoes multi-stage pressure reduction, gas-liquid separation is obtained to obtain a gas phase system and a non-gas phase system, and the non-gas phase system is filtered by an ultrafiltration membrane made of ceramic material, Obtain the first solid phase, wherein the waste water obtained by filtration is returned to the supercritical oxidation treat...

Embodiment 3

[0048] The method for reclaiming rhodium from octanoic acid rhodium mother liquor, comprises the steps:

[0049] (1) mix octanoic acid rhodium mother liquor and acetic acid with mass ratio 1:2 and carry out pulping process, obtain slurry;

[0050](2) After the slurry and wastewater are mixed, the flow ratio of the slurry and wastewater into the three channels is determined by the mass and calorific value, so that the calorific value of the slurry and wastewater is mixed at 4-6MJ / kg, and oxygen is introduced as an oxidant , carry out supercritical oxidation treatment, after the material from the supercritical oxidation reactor undergoes multi-stage pressure reduction, gas-liquid separation is obtained to obtain a gas phase system and a non-gas phase system, and the non-gas phase system is filtered by an ultrafiltration membrane made of ceramic material, Obtain the first solid phase, wherein the waste water obtained by filtration is returned to the supercritical oxidation treatm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com