Metal organic framework modified stannous sulfide composite photocatalyst as well as preparation method and application thereof

A metal-organic framework and stannous sulfide technology, applied in the field of photocatalysis, can solve the problems of high electron-hole recombination rate of stannous sulfide, affecting light absorption efficiency, poor photocatalytic activity, etc., and achieve photogenerated electron-hole utilization High efficiency, high practical application value, and high photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

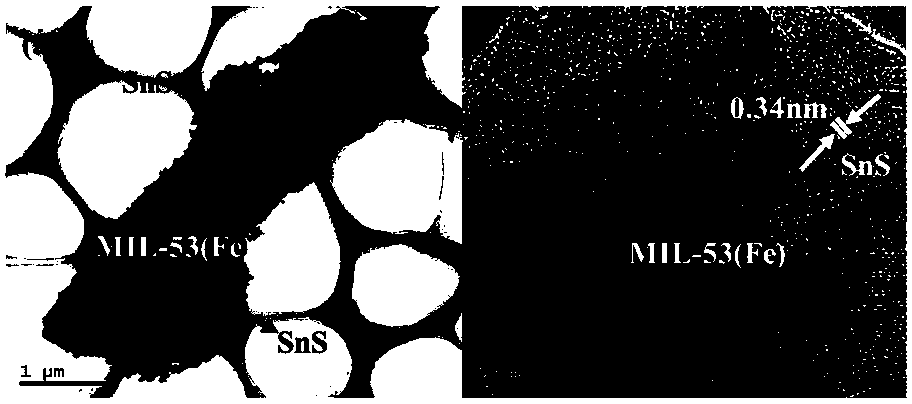

[0041] A metal-organic framework modified stannous sulfide composite photocatalyst, the metal-organic framework modified stannous sulfide composite photocatalyst is supported by a metal-organic framework, and the metal-organic framework is loaded with stannous sulfide, wherein the metal-organic framework is MIL-53( Fe).

[0042] In this example, the mass percentage of MIL-53(Fe) in the metal-organic framework-modified stannous sulfide composite photocatalyst is 6.63%.

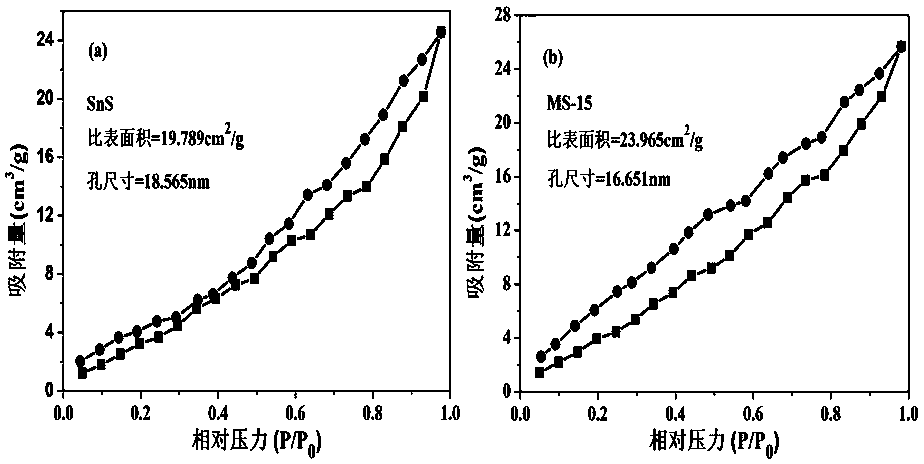

[0043] In this example, the specific surface area of the MOF-modified stannous sulfide composite photocatalyst is 23.965m 2 / g.

[0044] In this embodiment, MIL-53(Fe) is rod-shaped, and stannous sulfide is block-shaped.

[0045] The preparation method of the metal-organic framework modified stannous sulfide composite photocatalyst of the above-mentioned present embodiment comprises the following steps:

[0046] (1) Preparation of rod-shaped MIL-53(Fe):

Embodiment 2

[0061] A metal-organic framework-modified stannous sulfide composite photocatalyst, which is basically the same as the metal-organic framework-modified stannous sulfide composite photocatalyst of Example 1, the difference being: the metal-organic framework-modified stannous sulfide composite photocatalyst of Example 2 The mass percent content of MIL-53(Fe) in it is 9.95%.

[0062] A method for preparing the metal-organic framework-modified stannous sulfide composite photocatalyst of the above-mentioned present embodiment is basically the same as the preparation method of the metal-organic framework-modified stannous sulfide composite photocatalyst of Example 1, the difference being: the method of embodiment 2 The amount of rod-shaped MIL-53(Fe) in step (2.1) was 15 mg.

[0063] The metal-organic framework modified stannous sulfide composite photocatalyst prepared in Example 2 was named MS-15.

[0064] figure 1 It is the SEM figure of the metal-organic framework modified stan...

Embodiment 3

[0070] A metal-organic framework-modified stannous sulfide composite photocatalyst, which is basically the same as the metal-organic framework-modified stannous sulfide composite photocatalyst of Example 1, the difference being: the metal-organic framework-modified stannous sulfide composite photocatalyst of Example 3 The mass percent content of MIL-53(Fe) in it is 13.3%.

[0071] A kind of preparation method of the metal-organic framework modified stannous sulfide composite photocatalyst of the above-mentioned present embodiment is basically the same as the preparation method of the metal-organic framework modified stannous sulfide composite photocatalyst of embodiment 1, the difference is: embodiment 3 The dosage of rod-shaped MIL-53(Fe) in step (2.1) was 20 mg.

[0072] The metal-organic framework modified stannous sulfide composite photocatalyst prepared in Example 3 was named MS-20.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com