Method for producing amorphous precursor serving as anode material of lithium ion battery

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, secondary batteries, chemical instruments and methods, etc., can solve problems such as long reaction time, high processing cost, and increased internal resistance of materials, and achieve low requirements for reaction conditions, Low-cost source, easy-to-response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

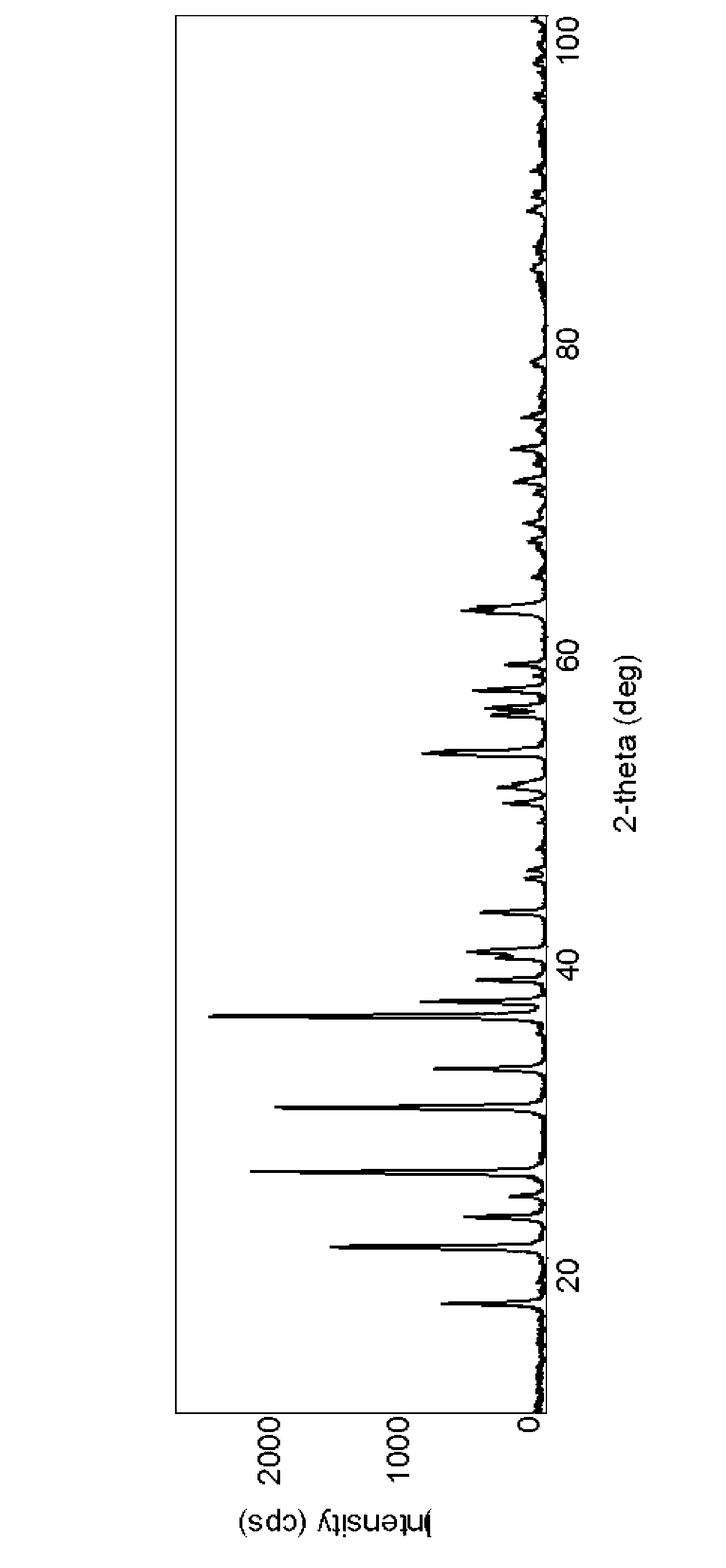

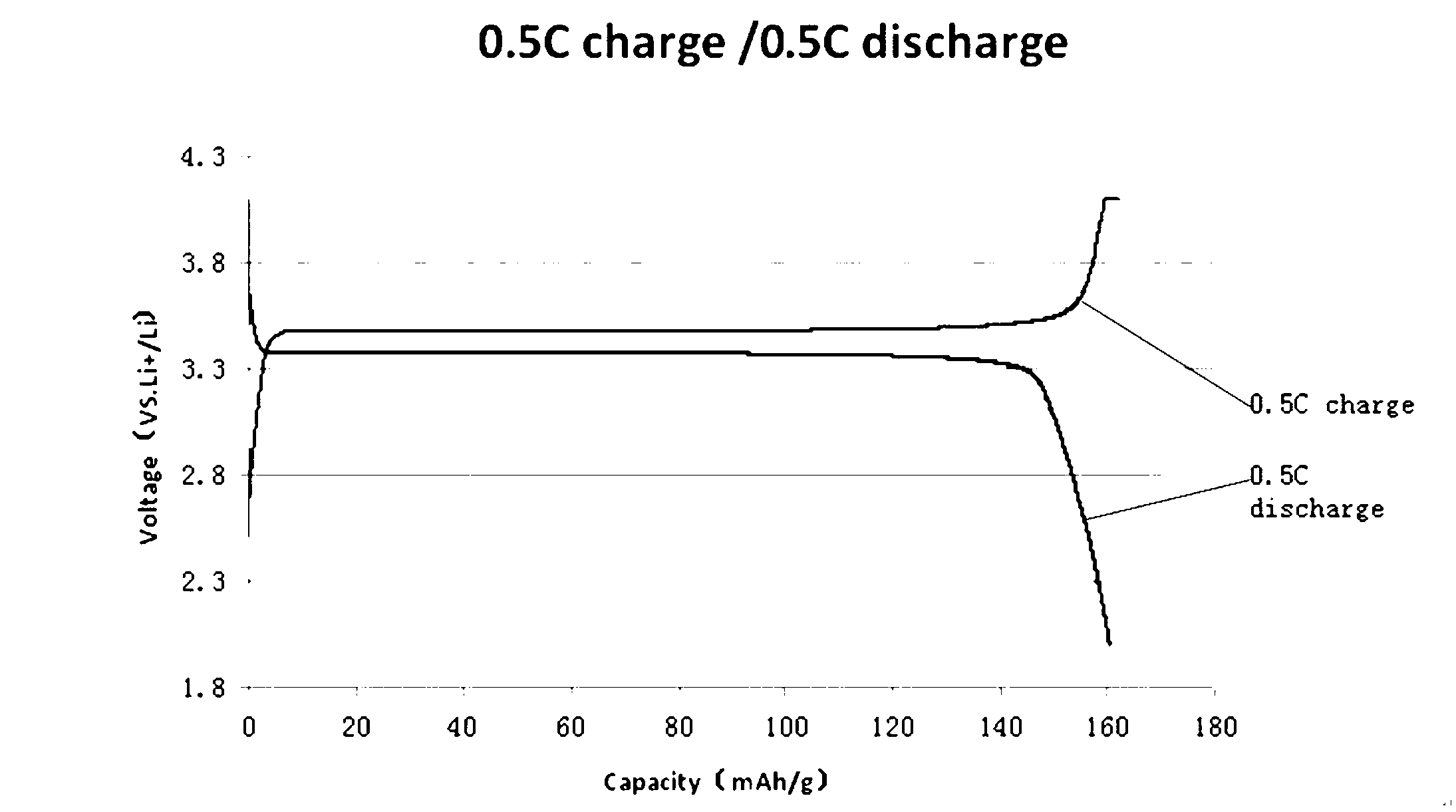

[0044] Example LiFePO 4 Synthesis of cathode active materials

[0045] In a specific embodiment of the present invention, LiFePO 4 It can be synthesized in the following ways. Reagents used in this synthesis included iron (II) sulfate (2.0M), ammonium dihydrogen phosphate (2.0M). All solutions were prepared using deionized water degassed by boiling for 10 minutes. In this test, the reaction was carried out in a low-temperature reactor with a circulating cooling system, and the temperature was controlled at 10°C±2°C during the entire reaction process. Reagents were added using a coprecipitation reactor with a 2L jacketed reactor vessel equipped with a pH controller and using a digital peristaltic pump. During the process, the addition of ammonium dihydrogen phosphate is automatically controlled by the pH controller, and the peristaltic pump on the reactor is used to add ammonium dihydrogen phosphate as needed. Reaction The mixture solution in the reactor was stirred using ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com