Method for preparing FeSe-based superconducting material

A technology of superconducting materials and ball-to-material ratio, which is applied in the field of superconducting material preparation, can solve the problems that the superconducting phase is difficult to achieve Unicom, does not have superconducting performance, and the material has low current-carrying performance, so as to shorten the time required for ball milling , reduce the original particle size, and repeatable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

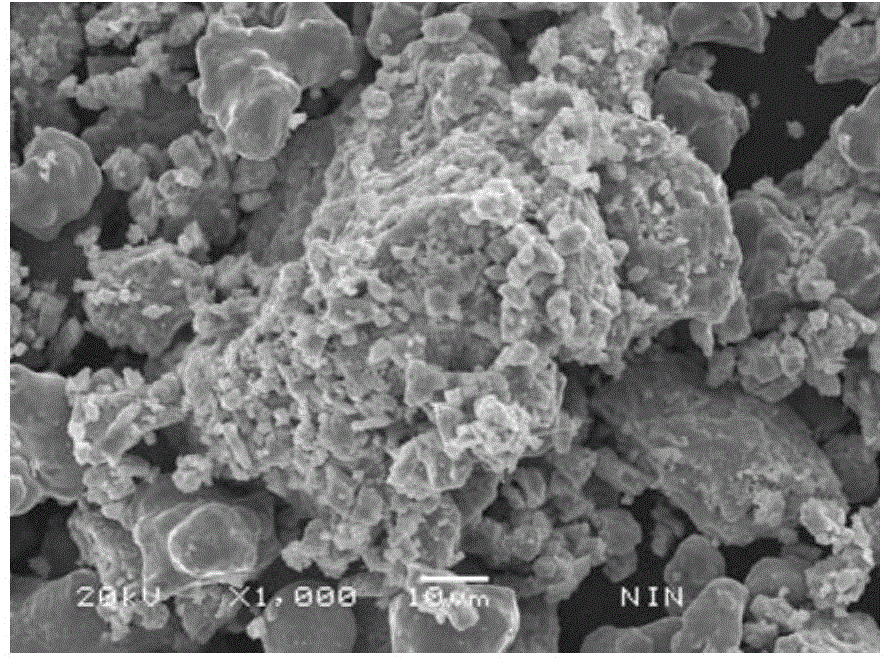

Embodiment 1

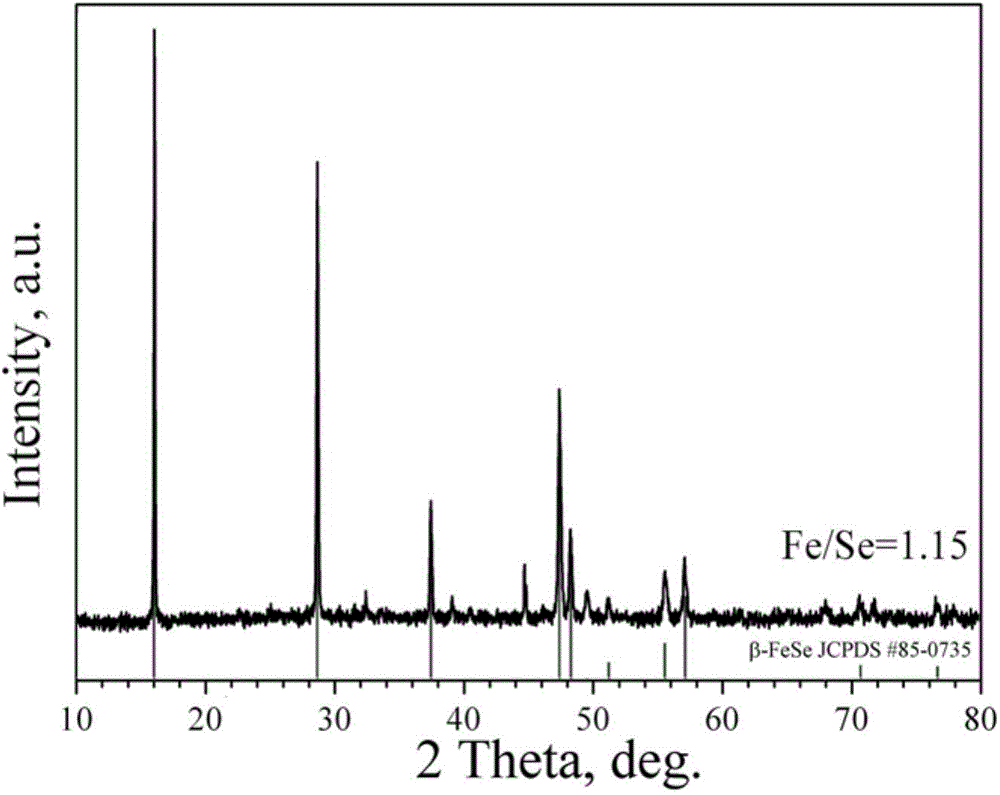

[0034] Step 1. In a glove box full of inert gas, place the mixed powder in a vacuum ball mill jar, then seal the vacuum ball mill jar and take it out; the mixed powder is made of iron powder and selenium powder with a molar ratio of 1.15:1 composition, the iron powder is reduced iron powder, the mass purity of the iron powder is not less than 99%, and the mass purity of the selenium powder is not less than 99%;

[0035] Step 2. Place the vacuum ball milling tank containing the mixed powder in step 1 in a high-energy ball mill for high-energy ball milling. The specific process is:

[0036] Step 201: Under the condition that the rotational speed of the high-energy ball mill is 1740r / min, the mixed powder is subjected to high-energy ball milling for 20 minutes, and then the vacuum ball mill tank is taken out and soaked in liquid nitrogen until the mixed powder is cooled below 0°C; the high-energy ball mill The ball-to-material ratio of processing is 1:4;

[0037] Step 202, repea...

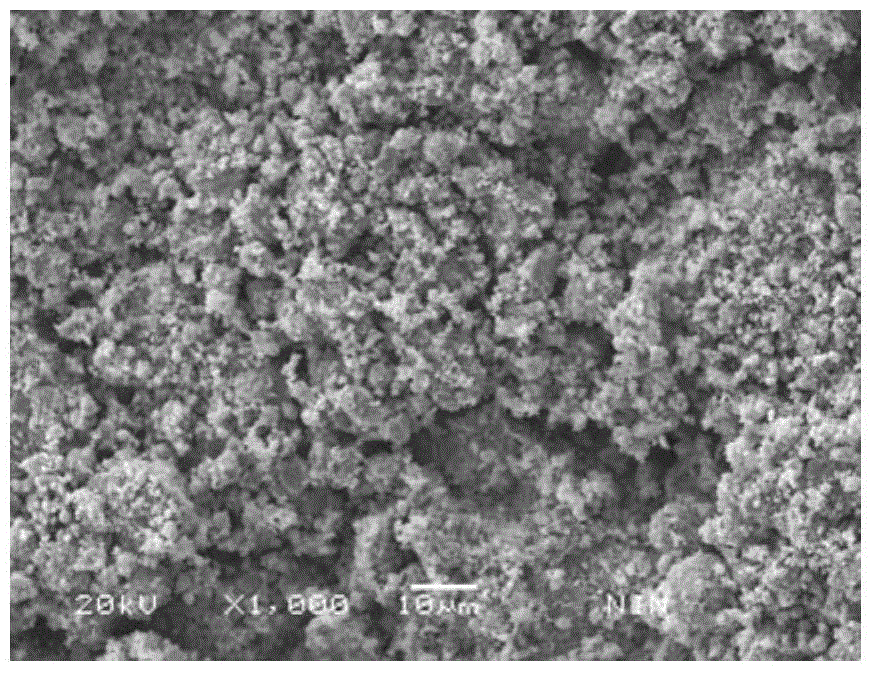

Embodiment 2

[0044] Step 1. In a glove box full of inert gas, place the mixed powder in a vacuum ball mill jar, then seal the vacuum ball mill jar and take it out; the mixed powder is composed of iron powder and selenium powder with a molar ratio of 1.25:1 composition, the iron powder is reduced iron powder, the mass purity of the iron powder is not less than 99%, and the mass purity of the selenium powder is not less than 99%;

[0045] Step 2. Place the vacuum ball milling tank containing the mixed powder in step 1 in a high-energy ball mill for high-energy ball milling. The specific process is:

[0046] Step 201: Under the condition that the rotational speed of the high-energy ball mill is 1800r / min, the mixed powder is subjected to high-energy ball milling for 15 minutes, and then the vacuum ball mill tank is taken out and soaked in liquid nitrogen until the mixed powder is cooled below 0°C; the high-energy ball mill The ratio of ball to material to be processed is 1:6;

[0047] Step 2...

Embodiment 3

[0052] Step 1. In a glove box full of inert gas, place the mixed powder in a vacuum ball mill jar, then seal the vacuum ball mill jar and take it out; the mixed powder is made of iron powder and selenium powder with a molar ratio of 0.9:1 composition, the iron powder is reduced iron powder, the mass purity of the iron powder is not less than 99%, and the mass purity of the selenium powder is not less than 99%;

[0053] Step 2. Place the vacuum ball milling tank containing the mixed powder in step 1 in a high-energy ball mill for high-energy ball milling. The specific process is:

[0054] Step 201. Under the condition that the rotational speed of the high-energy ball mill is 1500r / min, the mixed powder is subjected to high-energy ball milling for 30 minutes, and then the vacuum ball mill tank is taken out and soaked in liquid nitrogen until the mixed powder is cooled below 0°C; the high-energy ball mill The ratio of ball to material to be processed is 1:10;

[0055] Step 202, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com