Bismuth molybdate/titanium carbide heterojunction two-dimensional photocatalytic material as well as preparation method and application thereof

A photocatalytic material, titanium carbide technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve complex preparation methods of two-dimensional layered materials, catalytic Performance impact is large, harsh conditions and other issues, to achieve the effect of improving catalytic performance, inhibiting recombination, and accelerating separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A bismuth molybdate / titanium carbide heterojunction two-dimensional photocatalytic material comprises layered bismuth molybdate and titanium carbide nanosheets, and the layered bismuth molybdate is supported on the titanium carbide nanosheets.

[0038] In this embodiment, the mass ratio of titanium carbide nanosheets and layered bismuth molybdate in the bismuth molybdate / titanium carbide heterojunction two-dimensional photocatalytic material is 2:1000.

[0039] In this embodiment, the layered bismuth molybdate has a single-layer layered structure with a thickness of 1.02 nm; the thickness of titanium carbide nanosheets is 1.98 nm.

[0040] A preparation method of the bismuth molybdate / titanium carbide heterojunction two-dimensional photocatalytic material of the above-mentioned present embodiment, comprising the following steps:

[0041] (1) Preparation of titanium carbide nanosheets

[0042] (1.1) Accurately weigh 0.5g of titanium aluminum carbide and add it to the mi...

Embodiment 2

[0047] A bismuth molybdate / titanium carbide heterojunction two-dimensional photocatalytic material is basically the same as in Example 1, the only difference being that in the bismuth molybdate / titanium carbide heterojunction two-dimensional photocatalytic material in Example 2, the titanium carbide nanometer The mass ratio of flakes and layered bismuth molybdate is 5:1000.

[0048] A preparation method of the bismuth molybdate / titanium carbide heterojunction two-dimensional photocatalytic material in the above-mentioned present embodiment is basically the same as the preparation method in Example 1, the only difference is that the raw materials in the preparation method in Example 2 The dosage of the two-dimensional layered titanium carbide nanosheets is 0.0031 g.

[0049] The bismuth molybdate / titanium carbide heterojunction two-dimensional photocatalytic material prepared in Example 2 is named "5:1000 bismuth molybdate / titanium carbide".

Embodiment 3

[0051] A bismuth molybdate / titanium carbide heterojunction two-dimensional photocatalytic material is basically the same as in Example 1, the only difference being that in the bismuth molybdate / titanium carbide heterojunction two-dimensional photocatalytic material in Example 3, titanium carbide nanometer The mass ratio of flakes and layered bismuth molybdate is 10:1000.

[0052] A preparation method of the bismuth molybdate / titanium carbide heterojunction two-dimensional photocatalytic material in the above-mentioned present embodiment is basically the same as the preparation method in Example 1, the only difference is that the raw materials in the preparation method in Example 3 The dosage of the two-dimensional layered titanium carbide nanosheets is 0.0062 g.

[0053] The bismuth molybdate / titanium carbide heterojunction two-dimensional photocatalytic material prepared in Example 3 is named "10:1000 bismuth molybdate / titanium carbide".

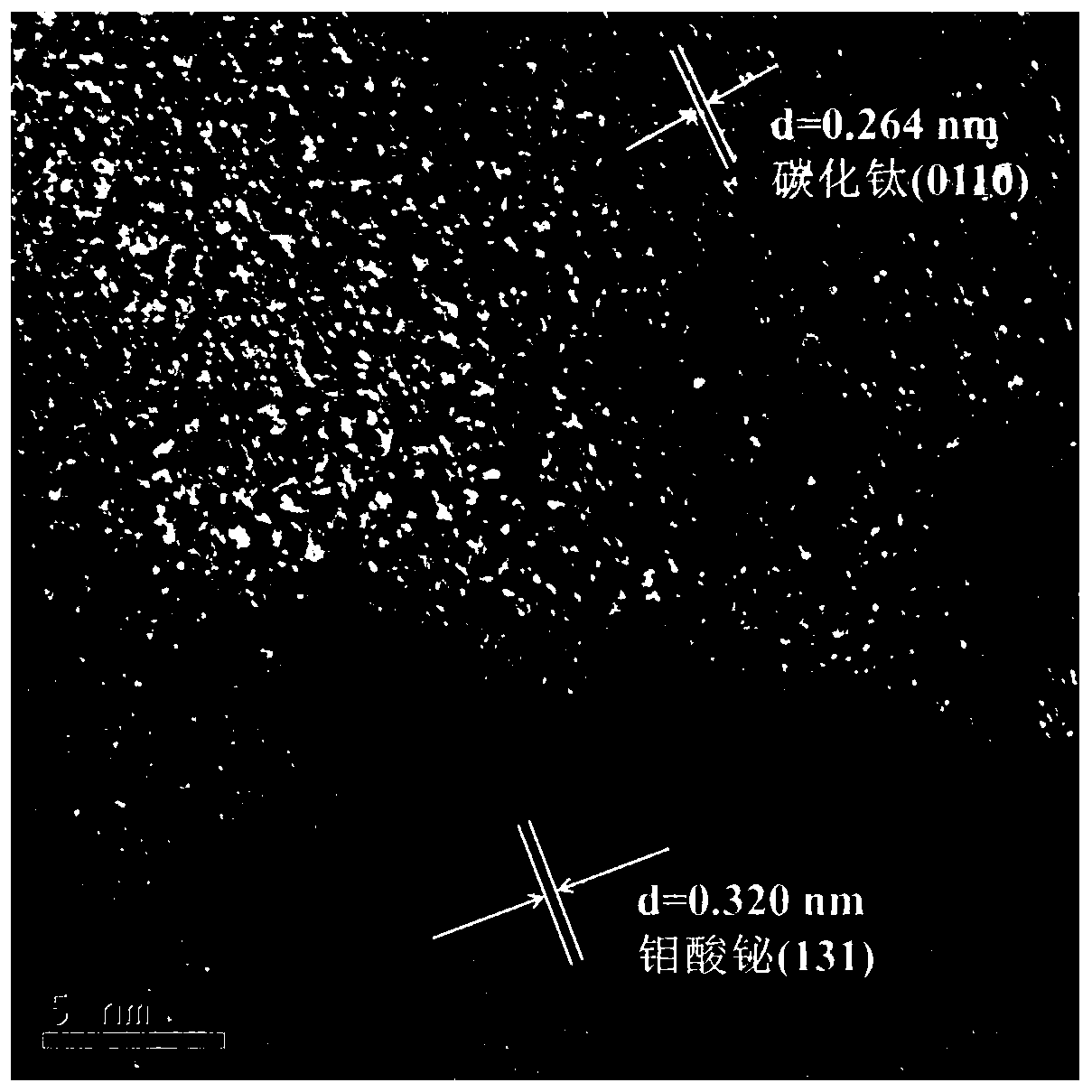

[0054] figure 1 It is a transmissi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com