Method for preparing formic acid

A technology of formic acid and methyl formate, which is applied in the field of formic acid preparation, can solve the problems of high energy consumption, long process, and easy reverse esterification reaction, etc., and achieve low energy consumption, short process, and effective control of reverse esterification reaction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

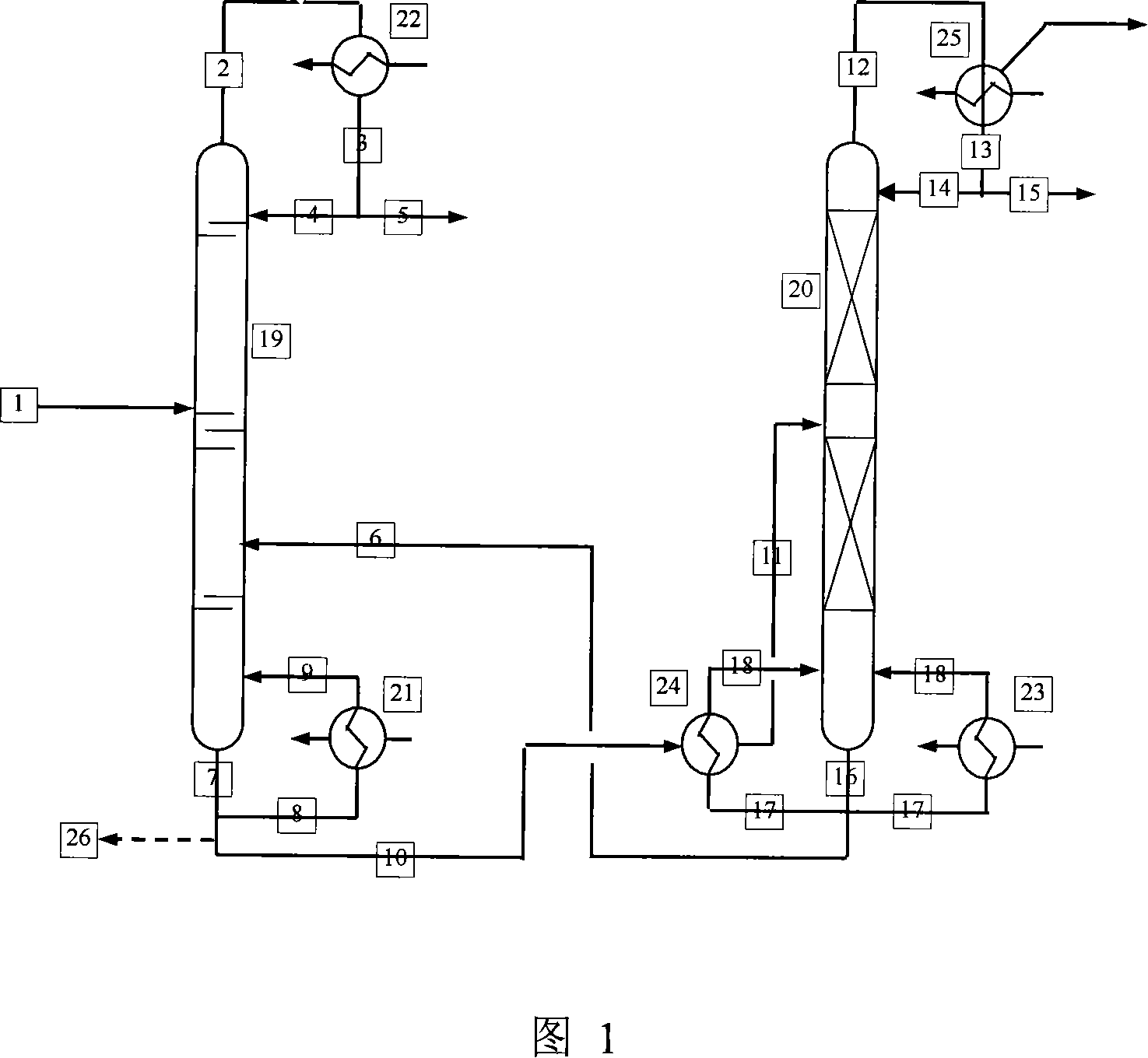

[0032] The present embodiment is the preparation method of high-purity formic acid, and its technological process is as shown in Figure 1, mainly comprises the following steps:

[0033] (1), hydrolysis reaction: make raw material water and methyl formate hydrolyze in the hydrolysis system (not drawn in Fig. 1), generate the hydrolysis mixture 1 containing water, formic acid, methyl alcohol and excess methyl formate;

[0034](2), pressurized distillation and separation: the hydrolysis mixture 1 containing water, formic acid, methanol and excess methyl formate obtained in the hydrolysis reaction of step (1) is introduced into the middle part of the first distillation tower 19;

[0035] This hydrolysis mixture 1 flow rate is 18087kg / h, wherein methyl formate 8124kg / h, methyl alcohol 2233kg / h, water 5319kg / h, formic acid 2411kg / h; This first distillation tower 19 is a tray tower, operating pressure 0.13MPa (G) , the tower top temperature is 109°C, the reflux ratio R=1.2;

[0036]...

Embodiment 2

[0045] What this embodiment is different from embodiment 1 is: do not use the second distillation tower, the first distillation tower still liquid directly as the formic acid product of 85% (wt), also do not have the second distillation tower still liquid to enter in the first distillation tower simultaneously lower part.

[0046] The operating conditions of the first distillation column are the same as in Example 1, and the feed 1 of the hydrolyzed mixture of the first distillation column 19 is the same as in Example 1.

[0047] The first distillation tower still liquid 10 of the present embodiment contains: water 407.7kg / h, formic acid 2504.4kg / h, add up to 2912.1kg / h, formic acid concentration 86.0% (wt);

[0048] In this embodiment, the production liquid 5 at the top of the first distillation tower contains: water 4874.7kg / h, methyl formate 8002.1kg / h, methanol 2298kg / h, a total of 15174.8kg / h.

[0049] Can get by calculating: formic acid rate of recovery: 103.87%, formic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com