Method for solving transverse cracks of ultra-thick plate billet corner by applying 3D (three-dimensional) spraying process

A technology of extra-thick slabs and transverse cracks, which is applied in the field of secondary cooling system in steelmaking and continuous casting, and can solve problems such as prone to micro-cracks and affecting the yield of steel slabs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

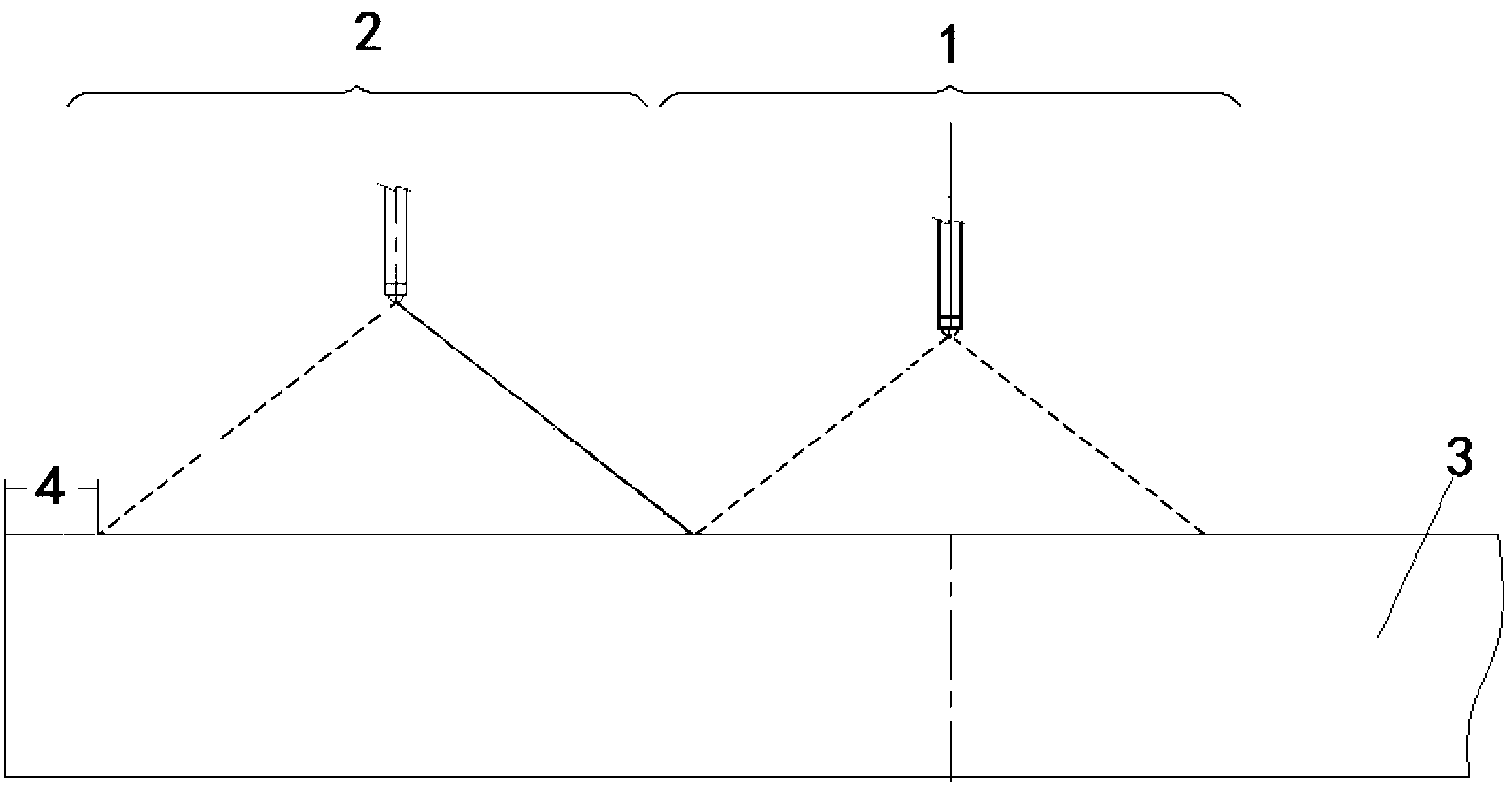

[0010] For extra-thick slabs with a thickness specification of 400mm, the cleaning and inspection results of the slabs were counted and analyzed, and the specific implementation of the 3D spray technology was determined. The steps are as follows:

[0011] 1) The fan-shaped segments for installing 3D nozzles are 1-8 segments;

[0012] 2) The principle of distribution of 3D nozzles in each segment is: according to the distribution of the secondary cooling zone;

[0013] 3) The distribution mode of the 3D nozzles of each segment along the casting direction: parallel and decreasing distribution;

[0014] 4) The distance from the spray edge of each segment 3D nozzle to the corner of the slab 4:

[0015] (1) -0.05m (Secondary Cooling Zone 6, corresponding to 1# segment)

[0016] (2) -0.05m (Secondary Cooling Zone 7, corresponding to 2# segment)

[0017] (3) 0.00m (Secondary cold zone 8, corresponding to 3#, 4# segment)

[0018] (4) 0.10m (Secondary Cooling Zone 9, corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com