Method for preparing polymers

A polymer and block polymer technology, applied in the field of copolymers, can solve the problems that the hydrogenation degree of the hydrogenation product needs to be improved, the reaction activity of the hydrogenation catalyst is low, and the reaction temperature is high, so as to reduce the preparation cost and improve the hydrogenation degree , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] The invention provides a kind of preparation method of polymer, and this method comprises the steps:

[0016] (1) mixing the glue solution of the unsaturated polymer with a hydrogenation catalyst, the hydrogenation catalyst containing organic compounds of organoaluminum and Group VIIIB metals;

[0017] (2) The mixture obtained in step (1) is subjected to the first hydrogenation reaction and the second hydrogenation reaction in the presence of hydrogen, the reaction temperature of the first hydrogenation reaction is -10 ~ 15 ° C, the second hydrogenation reaction The reaction temperature of hydrogenation reaction is 40-120 ℃;

[0018] (3) removing the solvent in the reaction product obtained in step (2).

[0019] In the method step (1) of the present invention, there is no particular limitation on the method of mixing the glue solution of the unsaturated polymer with the hydrogenation catalyst, and it can be various methods commonly used in the art, for example, adding ...

Embodiment 1-10

[0040] Examples 1-10 of the present invention serve to illustrate the preparation of the polymers of the present invention.

[0041] (1) dissolving the unsaturated polymer in an organic solvent to obtain a glue;

[0042] (2) Add the glue solution of unsaturated polymer in the reaction kettle, fill and discharge degassing, then add hydrogenation catalyst, mix;

[0043] (3) Filling with hydrogen, stirring, and reacting, the conditions of the reaction include: the reaction temperature is b°C, the hydrogen pressure is a MPa, and the reaction time is c minutes;

[0044] (4) be warming up to e ℃, keep the hydrogen pressure as d MPa, and react for f hours;

[0045] (5) The hydrogenated product was condensed and precipitated by ethanol, and dried in vacuum at 60° C. for 8 hours.

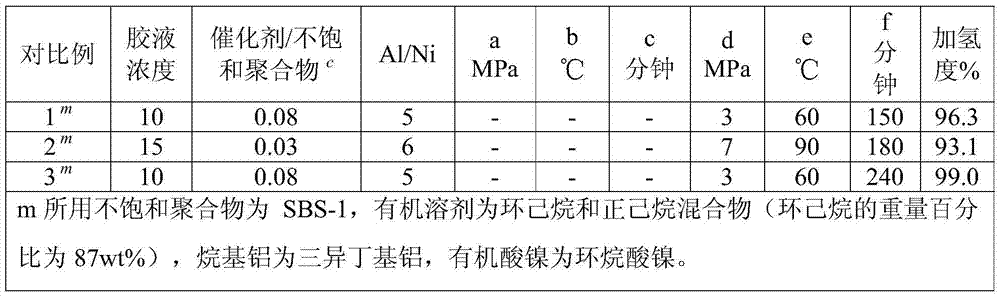

[0046] In embodiment 1-10, in unsaturated polymer, glue solution concentration (being the mass percentage concentration of unsaturated polymer in glue solution), organic solvent, Al / Ni in hydrogenation cat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com