Slump retention type solid poly carboxylic acid water reducing agent and preparation method thereof

A polycarboxylic acid and slump-preserving technology, applied in the field of slump-preserving solid polycarboxylate water reducing agent and its preparation, can solve the problems of inability to achieve green environmental protection, complex preparation process, and high equipment cost, and achieve a conversion rate of green and no Effects of pollution, simple operation and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

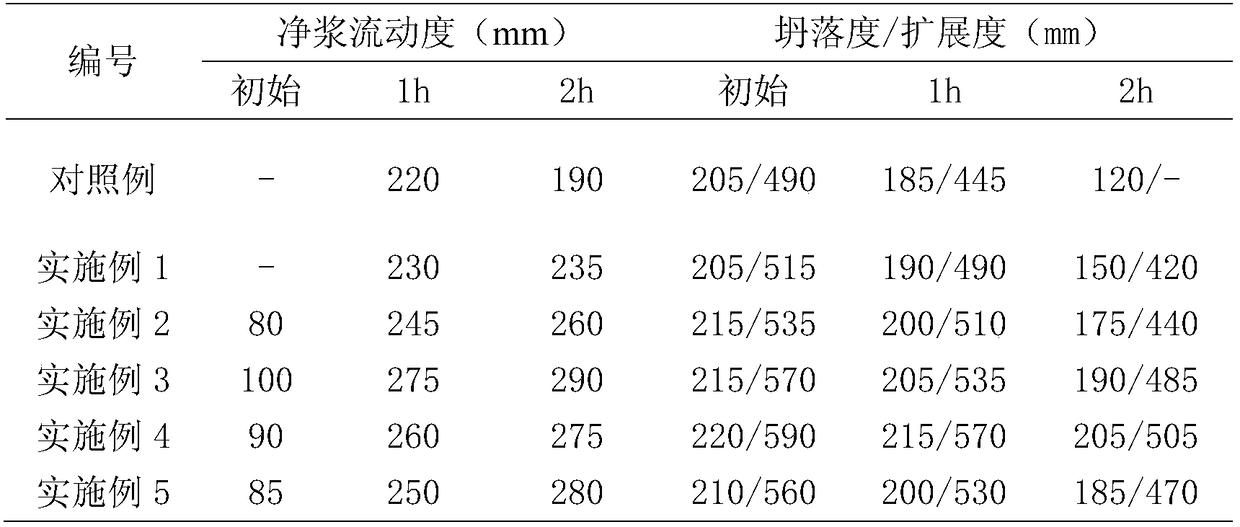

Examples

Embodiment 1

[0023] Step 1: Add 360g of allyl alcohol polyoxyethylene ether (weight average molecular weight 1200) into a four-necked flask reaction kettle, heat to 60°C and stir to melt it;

[0024] Step 2: Add 14.7 g of maleic anhydride and 1.75 g of cumene hydroperoxide to the molten allyl alcohol polyoxyethylene ether macromer obtained in step 1, and stir evenly to obtain a mixed solution A;

[0025] Step 3: Add dropwise the mixed solution B consisting of 2.0g N,N-diethylaniline, 1.2g mercaptopropionic acid and a small amount of water to the mixed solution A in step 2, then add dropwise the mixed solution B consisting of 58.8g maleic anhydride and 91.8g Mixed solution C composed of hydroxymethyl acrylate, 2.5g dimethyl azobisisobutyrate was added after 2 minutes, in which mixed solution B and mixed solution C were added dropwise for 2h and 1.5h respectively. The temperature of the process system is maintained between 65-70°C;

[0026] Step 4: Add 9 g of potassium hydroxide aqueous sol...

Embodiment 2

[0028] Step 1: Add 360g of methallyl polyoxyethylene ether (weight average molecular weight: 2400) into a four-necked flask reactor, heat to 65°C and stir to melt it;

[0029] Step 2: Add 5.4 g of methacrylic acid and 1.4 g of tert-butyl hydroperoxide to the molten methallyl polyoxyethylene ether macromonomer obtained in step 1, and stir evenly to obtain a mixed solution A;

[0030] Step 3: Add dropwise the mixed solution B consisting of 1.9g N,N-diethylaniline, 2.2g sodium methacrylate and a small amount of water to the mixed solution A in step 2, and then add dropwise the mixed solution B composed of 26.83g methyl Mixed solution C composed of acrylic acid and 52.2g hydroxyethyl methacrylate, add 2.6g of azobisisoheptanonitrile after 2 minutes, in which mixed solution B and mixed solution C were added dropwise for 2h and 1.5h respectively, and kept for 1h after dropping , the temperature of the system during the whole reaction process is maintained between 70-75°C;

[0031] ...

Embodiment 3

[0033] Step 1: Add 360g of prenol polyoxyethylene ether (weight average molecular weight 2400) into a four-necked flask reaction kettle, heat to 70°C and stir to melt;

[0034] Step 2: Add 6.75 g of acrylic acid and 1.6 g of ammonium persulfate to the molten prenol polyoxyethylene ether macromonomer obtained in Step 1, and stir evenly to obtain a mixed solution A;

[0035] Step 3: Add dropwise the mixed solution B consisting of 1.9g N,N-diethylaniline, 1.2g mercaptopropionic acid and a small amount of water to the mixed solution A in step 2, then add dropwise the mixed solution B consisting of 20.25g acrylic acid and 52.2g acrylic acid For the mixed solution C composed of hydroxyethyl ester, 2.8g of azobisisobutyronitrile was added after 2 minutes, and the mixed solution B and the mixed solution C were added dropwise for 2h and 1.5h respectively. Between 75-80°C;

[0036] Step 4: Add 10 g of sodium hydroxide aqueous solution with a mass fraction of 60% to neutralize the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com