Supramolecular polymerized carbon nitride photocatalyst and preparation method and application thereof

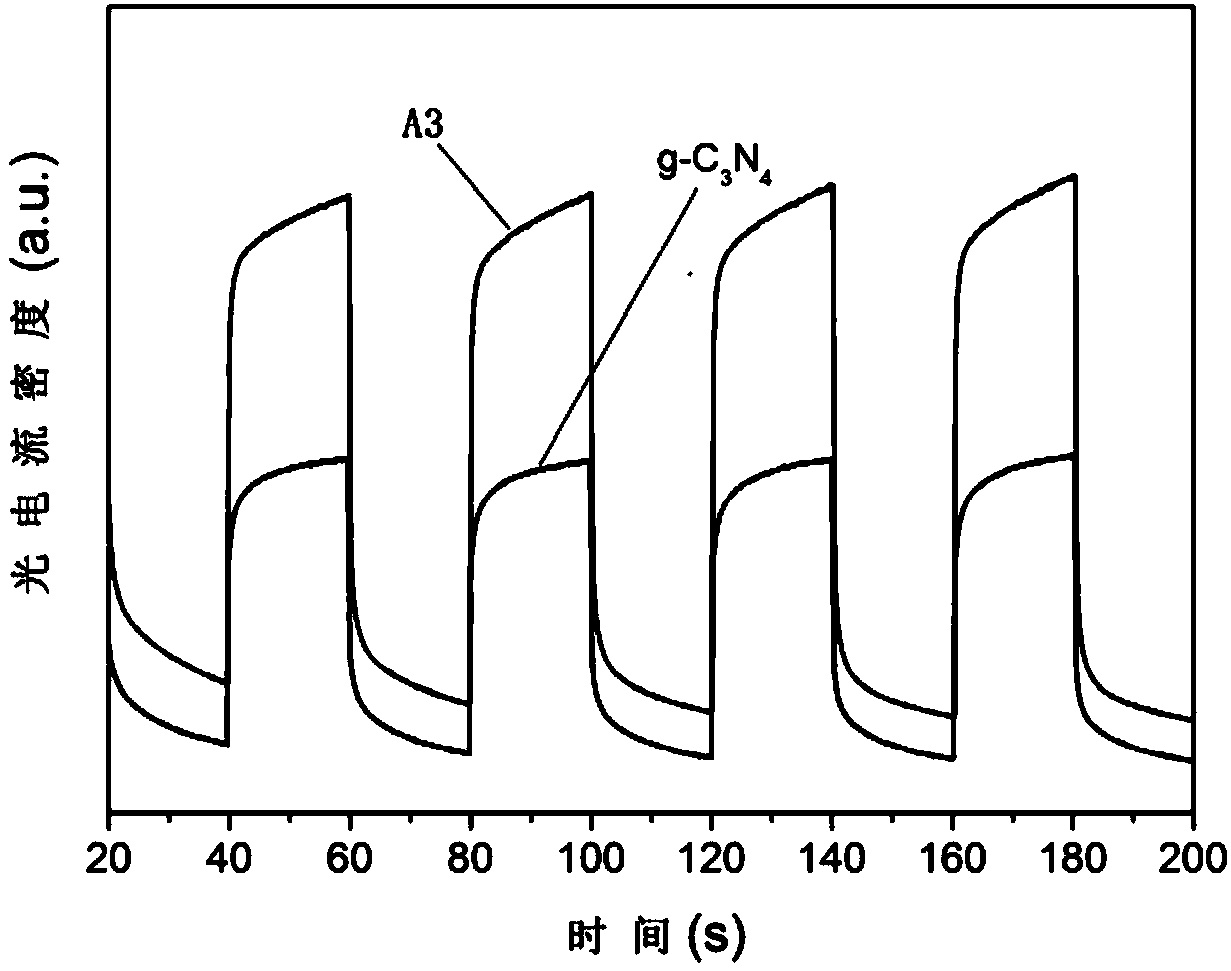

A supramolecular and catalyst technology, applied in the field of photocatalysis, can solve the problems of affecting the morphology and photocatalytic performance of carbon nitride, unfavorable large-scale mass production, high raw material cost, etc., and achieve superior photocatalytic degradation performance and good separation effect of photogenerated charges , the effect of high photogenerated charge separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

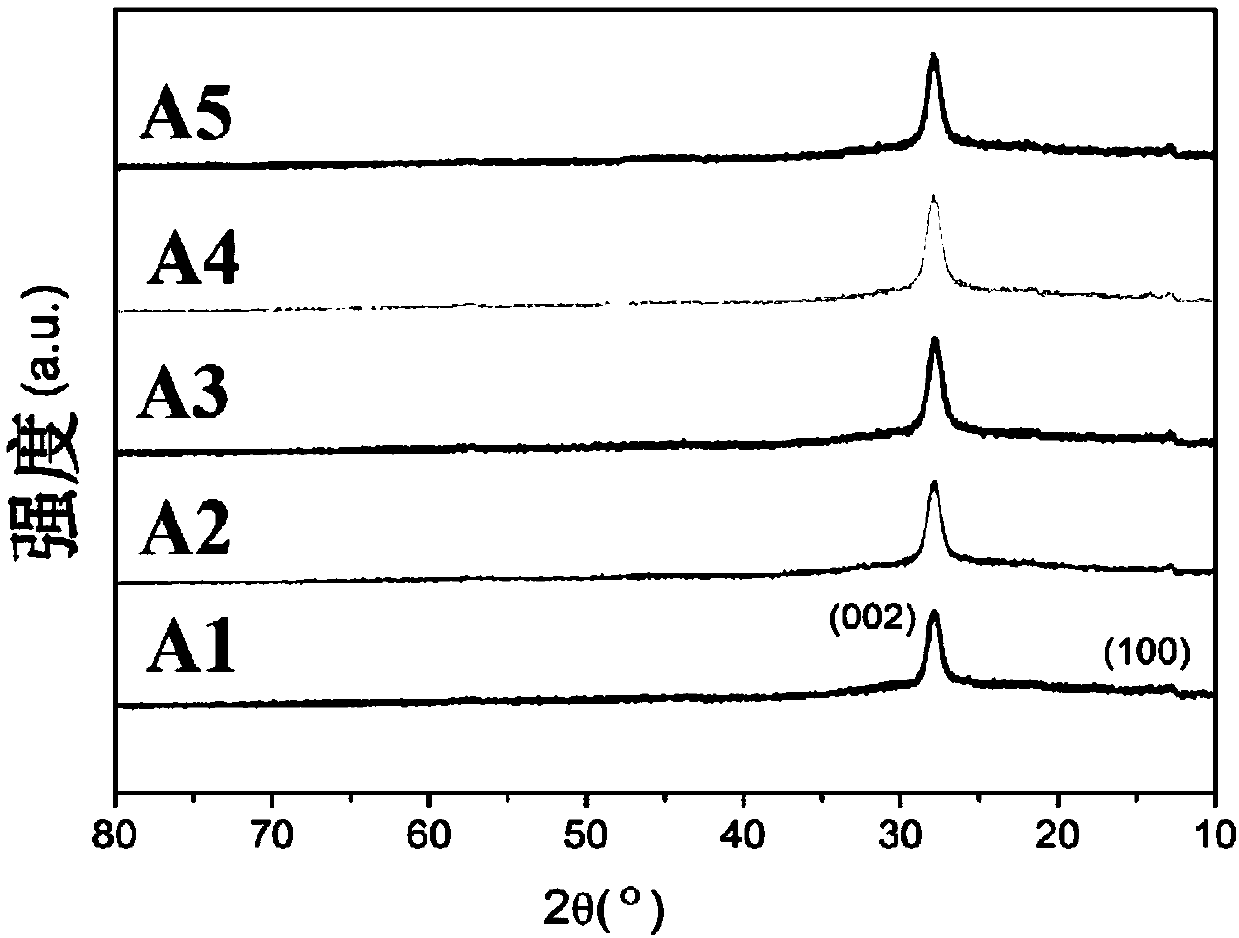

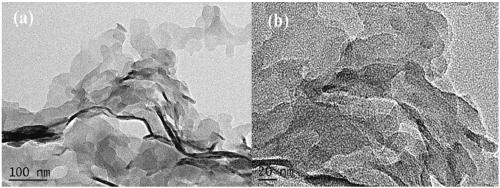

[0032] A preparation method of supramolecular polymerization carbon nitride photocatalyst, comprising the following steps:

[0033] (1) be 4: 4: 1 according to the ratio of the amount of substance of melamine, cyanuric acid and urea, take by weighing melamine, cyanuric acid and urea (the total mass of the three is 8g); Melamine, cyanuric acid and urea were added to dimethyl sulfoxide (the total volume of dimethyl sulfoxide used was 160mL), sonicated, so that melamine, cyanuric acid and urea were completely dissolved in dimethyl sulfoxide , to obtain melamine solution, cyanuric acid solution and urea solution.

[0034] (2) In a constant temperature water bath, heat the melamine solution, cyanuric acid solution and urea solution obtained in step (1) to 30°C, and keep the constant temperature, then these three solutions are mixed with each other, at a speed of 250r Molecular polymerization was carried out for 30 min under the electric stirring condition of / min. After the reacti...

Embodiment 2

[0038] A preparation method of supramolecular polymerization carbon nitride photocatalyst, comprising the following steps:

[0039] (1) According to the mass ratio of melamine, cyanuric acid and urea is 1:1:1, take by weighing melamine, cyanuric acid and urea (the total mass of the three is 8g); Polycyanuric acid and urea were added respectively in dimethyl sulfoxide (the total volume of dimethyl sulfoxide used was 160mL), sonicated, melamine, cyanuric acid and urea were respectively completely dissolved in dimethyl sulfoxide to obtain melamine solution, cyanuric acid solution and urea solution.

[0040] (2) In a constant temperature water bath, heat the melamine solution, cyanuric acid solution and urea solution obtained in step (1) to 60°C, and keep the constant temperature, then these three solutions are mixed with each other, at a speed of 250r Molecular polymerization was carried out for 30 min under the electric stirring condition of / min. After the reaction was complet...

Embodiment 3

[0044] A preparation method of supramolecular polymerization carbon nitride photocatalyst, comprising the following steps:

[0045] (1) According to the mass ratio of melamine, cyanuric acid and urea is 1:1:1, take by weighing melamine, cyanuric acid and urea (the total mass of the three is 8g); Polycyanuric acid and urea were added respectively in dimethyl sulfoxide (the total volume of dimethyl sulfoxide used was 160mL), sonicated, melamine, cyanuric acid and urea were respectively completely dissolved in dimethyl sulfoxide to obtain melamine solution, cyanuric acid solution and urea solution.

[0046] (2) In a constant temperature water bath, heat the melamine solution, cyanuric acid solution and urea solution obtained in step (1) to 30°C, and keep the constant temperature, then these three solutions are mixed with each other, at a speed of 250r Molecular polymerization was carried out for 30 min under the electric stirring condition of / min. After the reaction was complet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com